|

|

Post by Oily Rag on Jun 19, 2015 3:38:58 GMT

Most of you will not know me from a bar of soap, however I am excited as I will be in the UK soon with my lovely Ginger and we shall be taking in the sights at the sites and visiting some of my favourite railways. It will be Ginger's first time in the UK. I muck about with the full size choo choos as well, doing some work at the Rosewood Railway in Queensland. Fireman and general do all stuff but my love is in the workshop with small and large locos when ever I can. After waiting more than 8 years to build the house extension and have my model engineering desires sated with a new"Man Cave" workshop separate from my full time workshop I am now back again on my 5" Jimmy Jackson designed 060 simple but good passenger hauling loco. I started it in 1987, age 24 but my bicycle racing, then international work with Aussie cycling teams (team Mechanic) and my chosen path of full time professional expression (making lugged bespoke bicycles, "Llewellyn" marque) has kept me away from my engine. I still subscribe to ME since 1985. Any how, the first parts for my loco since 2005 have been made in my new workshop these last few weeks and that was very exciting for me. A set of four steam operated cylinder drains. YAY! Humble parts but a YAY for me! The loco when reassembled is close to test running on air.   Knife or shaving tool in action for the first time I like it and well worth the effort to make one up. Knife or shaving tool in action for the first time I like it and well worth the effort to make one up.  [/font] |

|

|

|

Post by Oily Rag on Jun 19, 2015 5:00:52 GMT

The 254S was pristine and I had it shipped out 5 years ago but it lived in it's crate till this year. I fitted metric dials to it, but crikey, Myford marked the dials in .025mm and not long marked in tenths. Better if it was .02 and long marked in tenths and every .20 numbered. Annoys me that people try to make metric machines work like imperial and think, .0254mm, but I will get over it eh! Maybe a DRO will be fitted and I shall revel in decadence . Changing spindal speeds is a right pain on the 254, maybe a electric speed set up one day will appease my fuss. It cuts accurate, after a lot of care setting up with test bars and level etc and I chase .005mm over 125mm lengths in my test set ups. Happy chap am I with this

Put an eye beam running through the workshop into the carport next to the house which was great for bringing machines in but will good for supporting boilers into and out of loco frames. Listening to the test cricket on the radio while working in here is just heaven with a cup of Yorkshire Black tea.

|

|

|

|

Post by Oily Rag on Jun 19, 2015 5:59:15 GMT

My current beginners loco Mostly in bits again   started in 1987 when I was doing a heck of lot of this for 15 years in OZ and a few season in France. No talent! started in 1987 when I was doing a heck of lot of this for 15 years in OZ and a few season in France. No talent!

|

|

|

|

Post by Oily Rag on Jun 19, 2015 6:07:05 GMT

The work shop in the next room under the house is for my chosen path of professional expression which is making bespoke bicycles.

www.llewellynbikes.com

www.flickr.com/photos/llewellyncustombicycles/albums

Different world now compared to when I started with frame builders as 16 yo git in 1979, but I have a solid market from the around the world and I have a UK and US agent for my propriety frame building castings, such as lugs and dropouts. So I am super interested in 3D printing waxes for casting loco parts for the next project.

|

|

|

|

Post by Oily Rag on Jun 19, 2015 6:20:32 GMT

|

|

|

|

Post by Oily Rag on Jun 19, 2015 6:34:47 GMT

I work on the full size ones as well

Fireman at the Rosewood Railway, and on the management committee, track work, doing our FB page.................dealing with members brain explosions, herding the cats.......................................

A lot for my first time posting but as my metal working projects progress in the months and years to come I will put some pics up of a beginner model engineer that started 28 years ago and got side lined and only just involved with steam the last 4 years.

As I said earlier, Ginger and I get on the big bird and will be at the mecca of steam actmco, THE UK. So I will be quiet till I make more metal bits in the new MAN CAVE

|

|

|

|

Post by ilvaporista on Jun 19, 2015 6:37:56 GMT

|

|

|

|

Post by Oily Rag on Jun 19, 2015 6:55:52 GMT

Thanks, I have lived tight, worked long days and hours for many years, now it is time to sate my need of railways and making things, besides bike frames.

Ya wonder at the sod who thought we count differently than in tens when working metric. May have as well marked the dials in cubits. I sit there counting the grads and writing them on paper and using a pencil to mark the dials to keep track of where I am going. Dro one day, and be rid of the clutch belt changing nonsense as well. My Taiwanese lathe is a joy with a gear box and dials marked imperial and metric. It is older than the Myford. However the 254 cuts so so accurate compared to my previous world. I also got a a cheap tool grinder at $1200 aud and learning to set up all my HSS profiles. Heaps of fun.

Gillford, oh yes, I know, but I am on holidays and Ginger wants to see the UK, not just coal smoke and nice hot steam oil, but I will have it on my list to steer towards tee hee. I want to shock them one day at Gilling when I finish #253, fly over with it in a crate via TNT international, and couple up to BR stock and run around. I bit over scale at 1/8 (3'6" gauge) but it would be fun :-)

I want to see flying legends at Duxford as well, I like warbirds. I subscribe to Aeroplane monthly.

|

|

|

|

Post by ilvaporista on Jun 19, 2015 8:34:27 GMT

Now far be it from me to be described as tight with money but..... The best way I find of viewing the Flying Legends is to go on the Friday, normal entry price apply and they are doing practice for most of the day (weather permitting) so you get to see the whole show but without paying the increased entry fee. Until a coupe of years ago Guildford used to be on the same weekend and when it coincided with Farnborough Airshow we would arrive on Friday morning at Stansted, go to the 'pre-show' at Duxford, set up for Guildford on Friday night, all weekend at the Steam Rally and on Monday morning was the first trade day of Farnborough (watched through the fence).... Me tight with money??? Never.....

|

|

|

|

Post by Oily Rag on Jun 21, 2015 23:10:44 GMT

Beginners stuff I know, but if one can be pointed to mistakes then I welcome to be corrected for own my progression of metal working skills.

Saturday arvo, ground out a male thread relief tool that could get closer up to the chuck. 1.7mm wide. Roughed out on the bench grinder, to the tool grinder for the final passes, then to the diamond hone and then a 1000 grit rub to polish off the four edges. Works a treat.  Then to the lathe, admission pipes to the steam chests. The drawing calls for brass so the PB hex stayed in the drawer for another job. Then to the lathe, admission pipes to the steam chests. The drawing calls for brass so the PB hex stayed in the drawer for another job.

The lovely Ginger sorted a red kettle that whistles to live in my MAN CAVE.

|

|

|

|

Post by Oily Rag on Jun 23, 2015 11:47:14 GMT

In 1987 I got my box of castings which included a couple of Phos bronze ones to be used for the exhaust and admission steam.

Filed them over, then turned, drilled and tapped and then a wee clean up with files and 320 grit and then a wire brush over   against the drawing against the drawing pack our bag tomorrow and we are on the big bird to the UK pack our bag tomorrow and we are on the big bird to the UK

|

|

|

|

Post by Oily Rag on Aug 21, 2015 23:02:36 GMT

Ginger and I are back from 5 weeks in the UK

Visited West Somerset, Lynton and Barnstaple, Vale of Reidol, Welsh Higland, Llangollen, Strapthey, Great Central, Severn Valley, some footplate rides, some driving and many goes at firing. I will be putting up my pics here www.flickr.com/photos/134218274@N08/albums

Any how, back to my local Rosewood Railway www.facebook.com/RosewoodRailway and I take on the workshop managers job (we are all 100 % volunteers) which is a big learning curve for me.

Got some recent time in my man cave working on the exhaust pipes. Discovered that my copy of ME hand book lists 1/2 x 26 TPI brass thread taping drill size as 11.8mm!

It seems it should be 11.5mm or 29/64".

I know it is simple stuff but super fun for me  I put a small diverter piece in the T, inspired by Doug Hewson article in EIM mag. Could not do any harm. I put a small diverter piece in the T, inspired by Doug Hewson article in EIM mag. Could not do any harm.

|

|

|

|

Post by Oily Rag on Mar 22, 2017 22:02:54 GMT

|

|

|

|

Post by Oily Rag on Mar 22, 2017 22:23:16 GMT

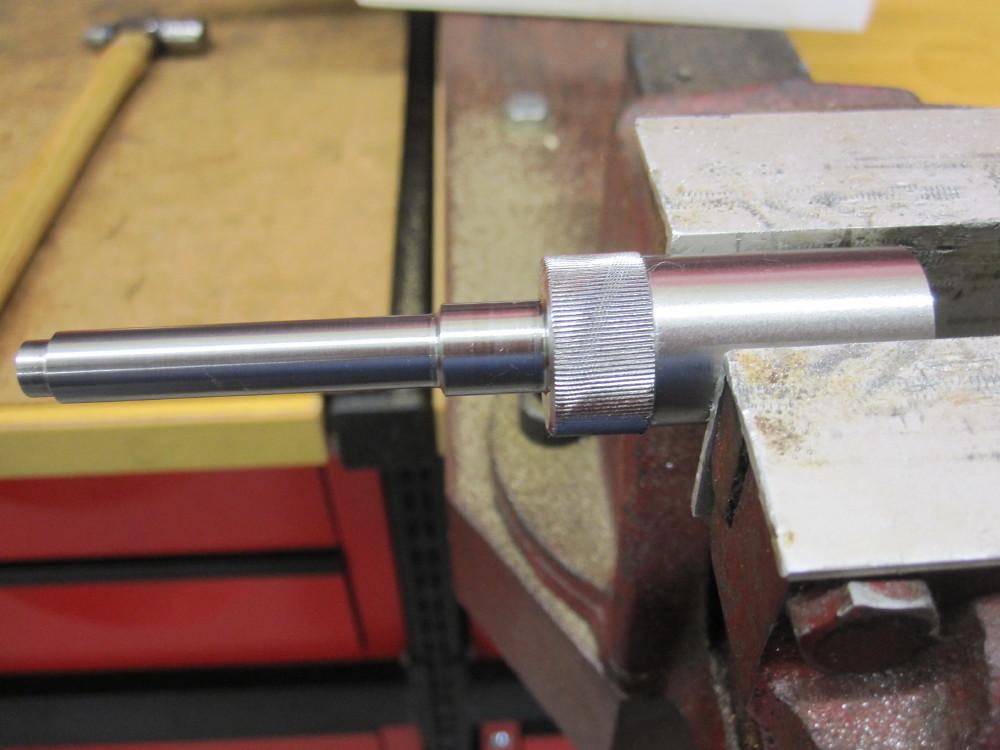

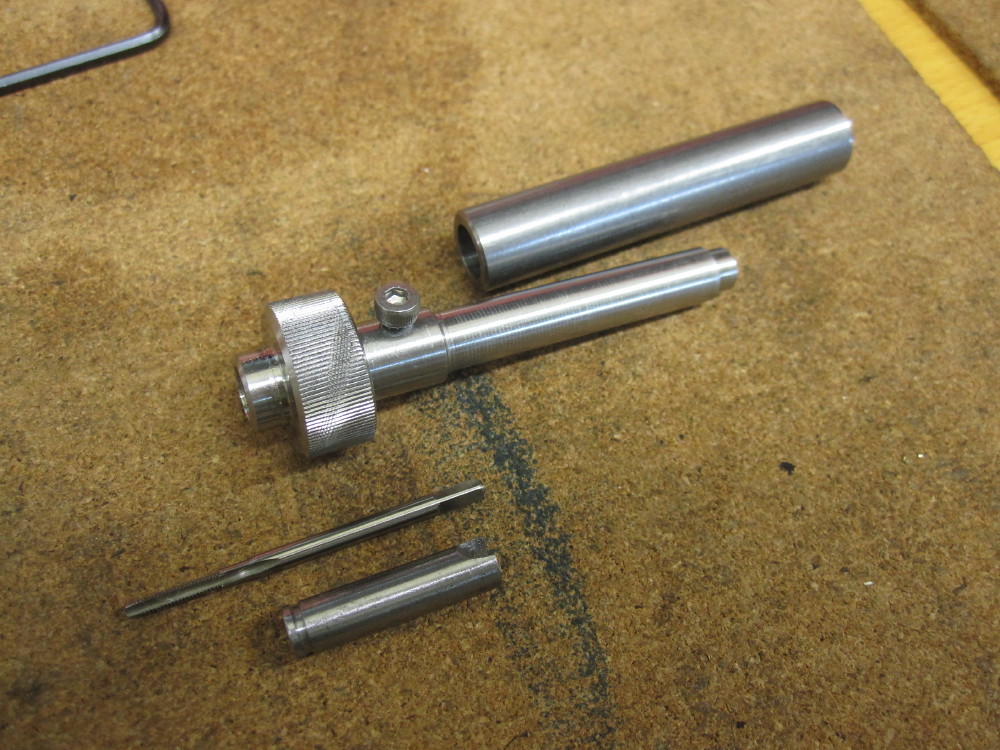

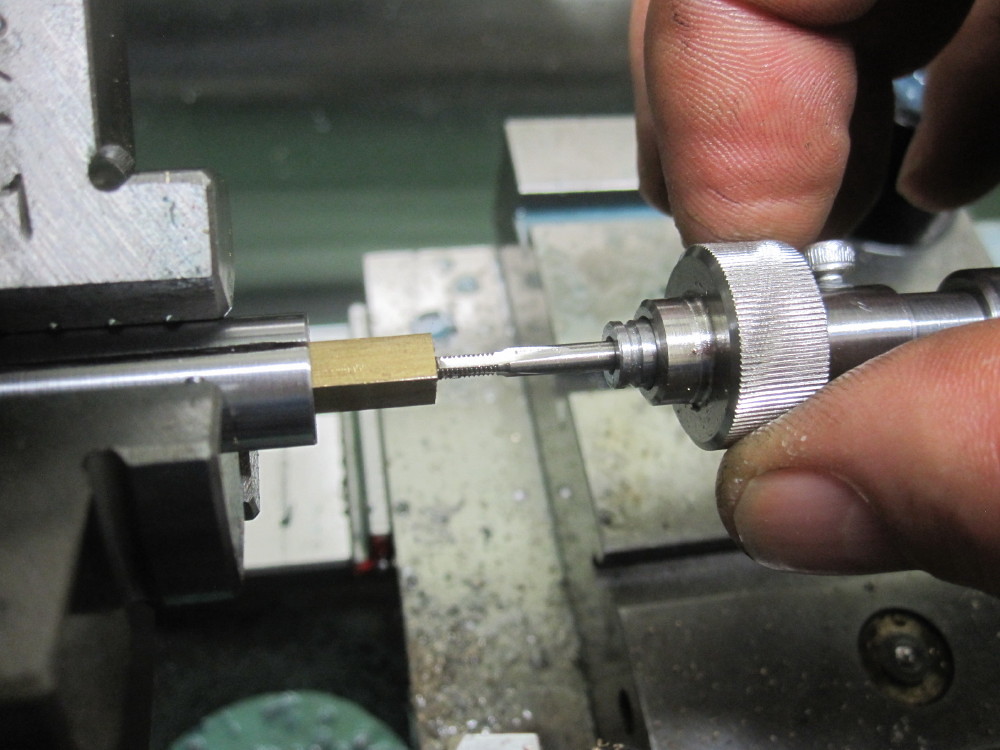

Brian has drawings of a small tail stock tap holder in his book. I have always wanted to make some sort of tap and die holders for the BA sizes, so these drawings got me going.

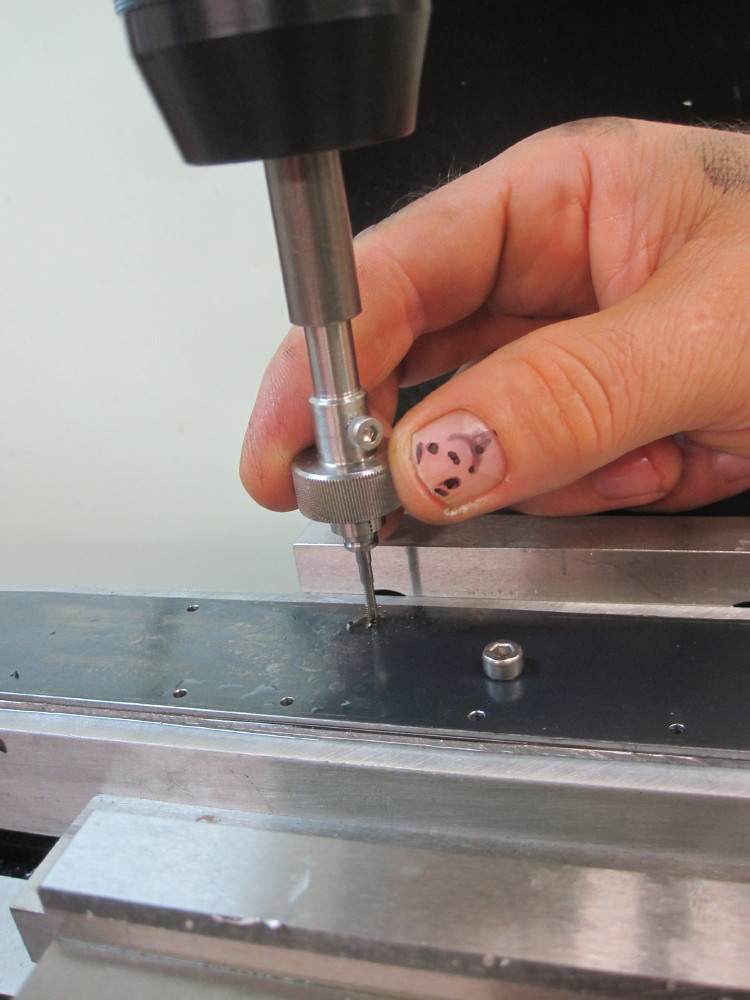

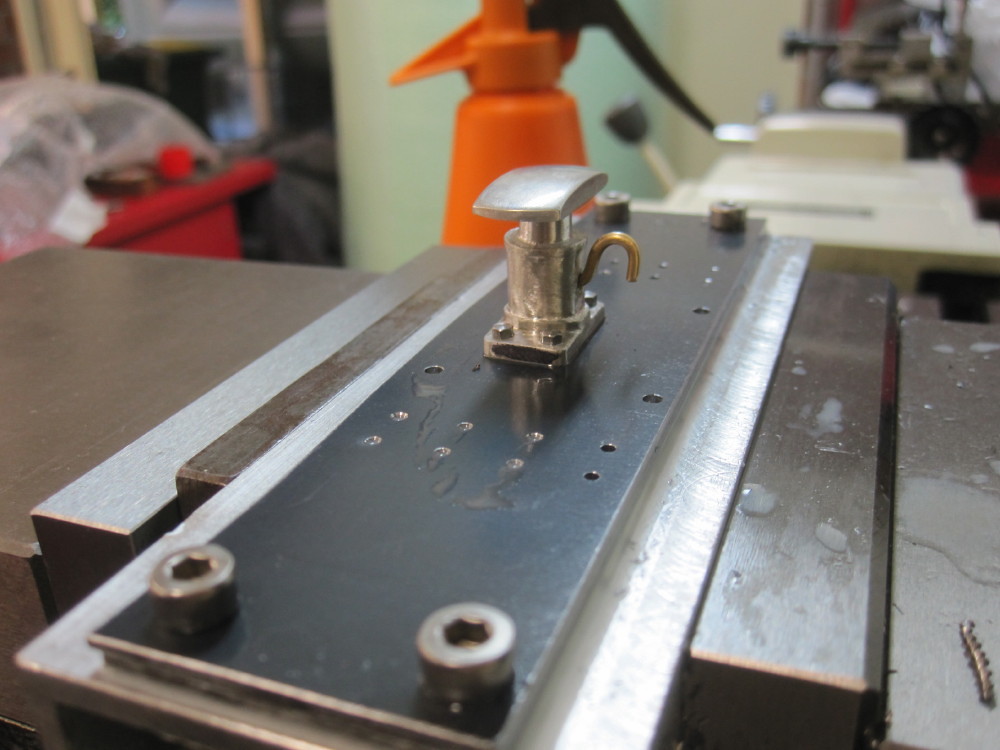

Grabbed a lump of stainless, because I had some and made a start. However Brian says drill it 1/8" to accept the BA taps.     BA taps come in all sorts of shank sizes. I got some top shelf and $ exy Sutton BA taps and measured. For 8BA I got 2.80mm and 10BA I got 2.50mm. I have some cheaper brands but I ignored those for the time being. Also the Sutton taps can vary up to .02mm in shanks size between the taper, inter and bottom taps, which surprised me. So I think, make the tool to fit all the small BA taps. I made sleeves from 1/4" RMS to fit each size tap that inserts with a light push fit. In small sizes I wanted to keep the accuracy of concentricity, or I fear broken taps. I am new to a lot of this so...................... The groove in the sleeve is for the finger nail to hook in to pull the sleeve out when changing. BA taps come in all sorts of shank sizes. I got some top shelf and $ exy Sutton BA taps and measured. For 8BA I got 2.80mm and 10BA I got 2.50mm. I have some cheaper brands but I ignored those for the time being. Also the Sutton taps can vary up to .02mm in shanks size between the taper, inter and bottom taps, which surprised me. So I think, make the tool to fit all the small BA taps. I made sleeves from 1/4" RMS to fit each size tap that inserts with a light push fit. In small sizes I wanted to keep the accuracy of concentricity, or I fear broken taps. I am new to a lot of this so...................... The groove in the sleeve is for the finger nail to hook in to pull the sleeve out when changing.

Drilled the 1.8mm and then used the new "Tapeie Holdie Thingie" and it worked a treat. I am the proud parent of my first 8BA threads.

OK, it is mundane for most but after many years of toil at my chosen path of professional expression the hours I spend in the "Red Room" (Llewellyn Locomotive Works) are most enjoyable, especially listening to the Test cricket in India on the radio.

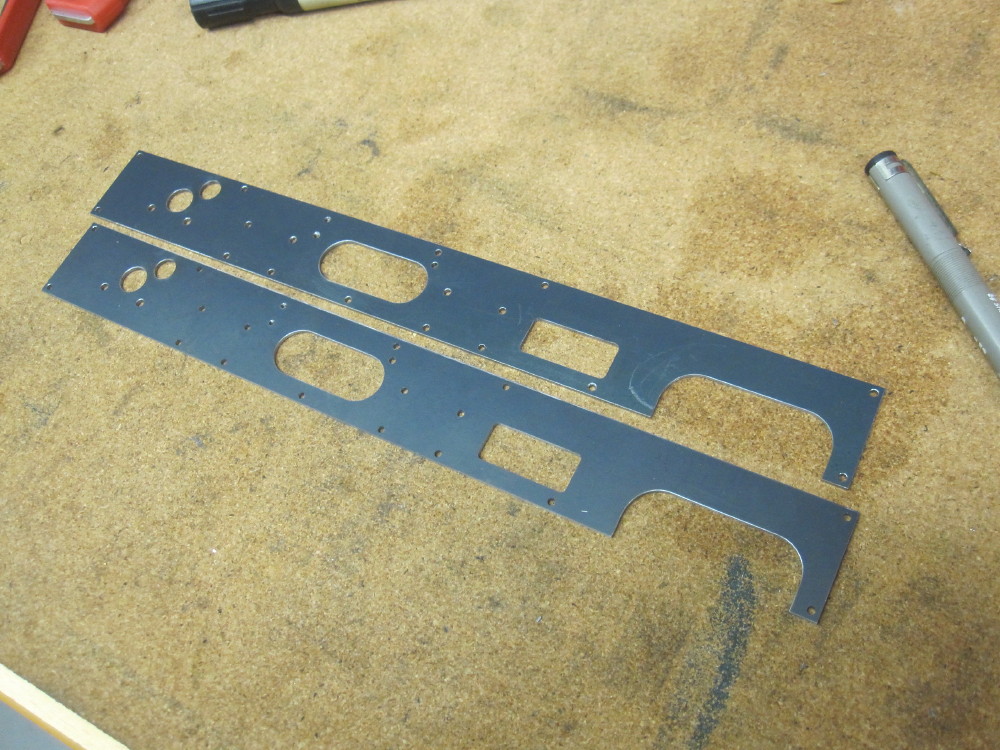

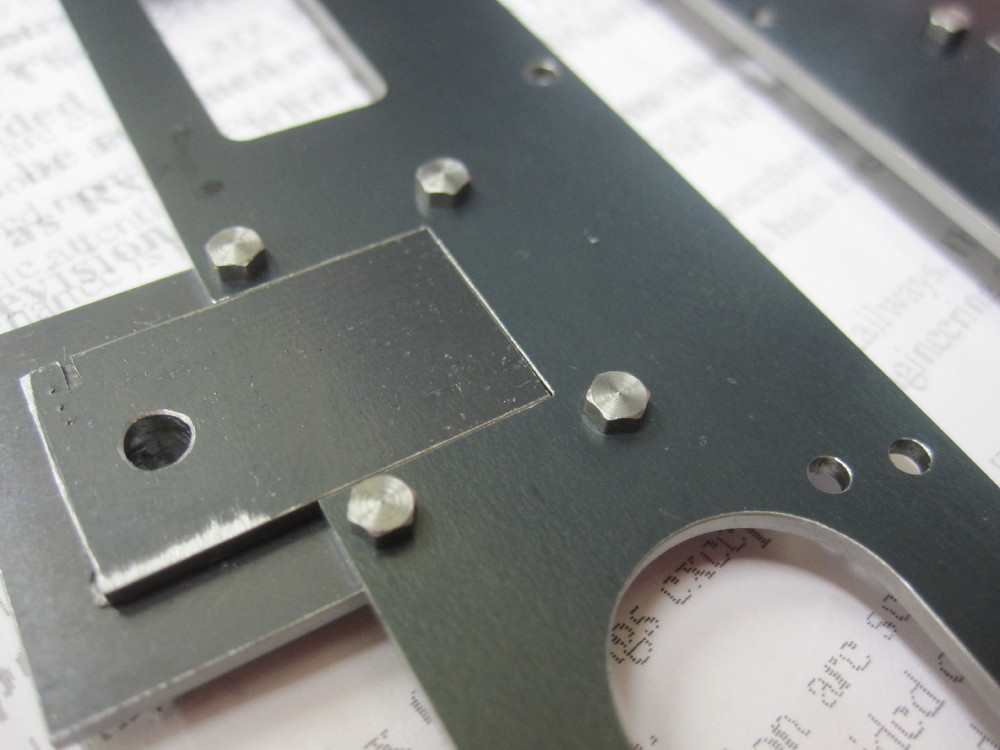

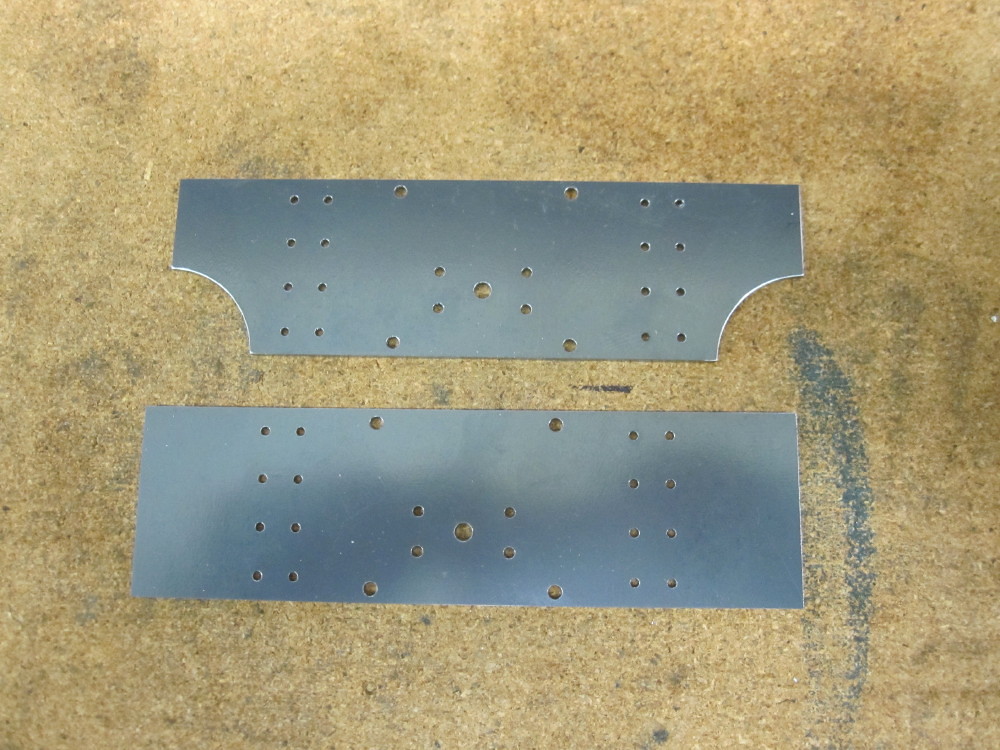

The frame edges etc will be milled last.

|

|

|

|

Post by quaintandrattly on Mar 23, 2017 8:11:06 GMT

Hey Dazza, look after that 720, it's my next project (in 7 1/4)

|

|

|

|

Post by Oily Rag on Mar 23, 2017 20:39:22 GMT

Hey Dazza, look after that 720, it's my next project (in 7 1/4) |

|

|

|

Post by Oily Rag on Mar 26, 2017 21:30:46 GMT

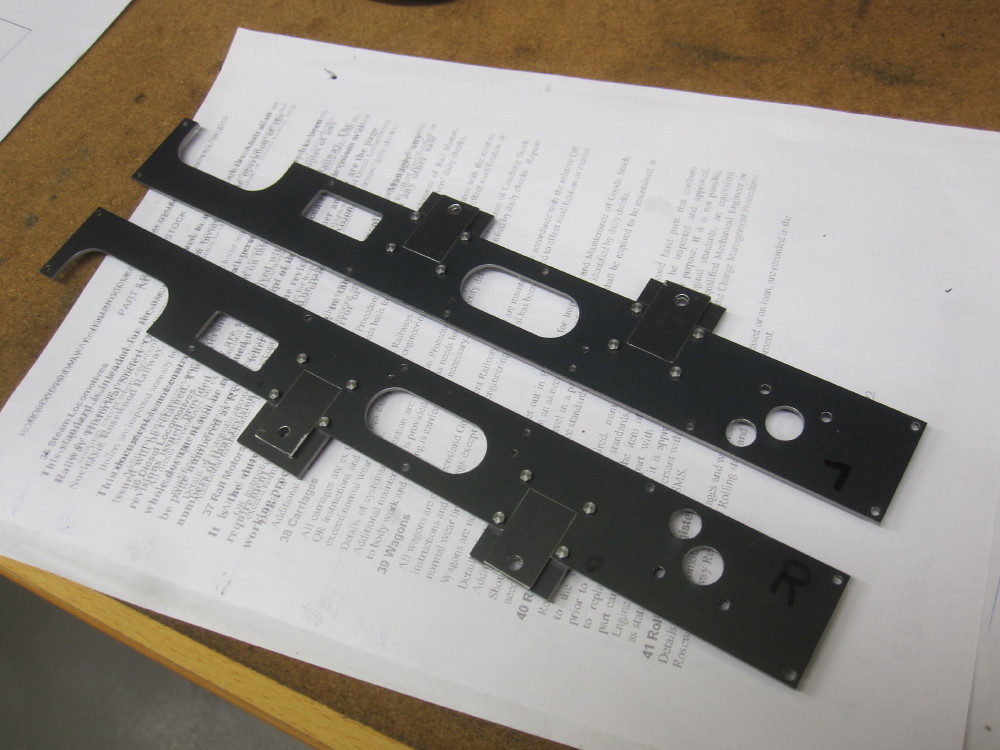

While listening to the forth test on the radio in the "Red Room", a very enjoyable afternoon of tasks on the mill drill.   I spent a lot of time to do a planned final cut with a climb mill pass. Mostly to teach my self techniques. I spent a lot of time to do a planned final cut with a climb mill pass. Mostly to teach my self techniques.

Before knock off time there was the clean off the lathe, mill/drill, sweep and mop the floor. I am pleased I sealed the concrete floor with epoxy. Before knock off time there was the clean off the lathe, mill/drill, sweep and mop the floor. I am pleased I sealed the concrete floor with epoxy. |

|

|

|

Post by Oily Rag on Apr 2, 2017 23:49:19 GMT

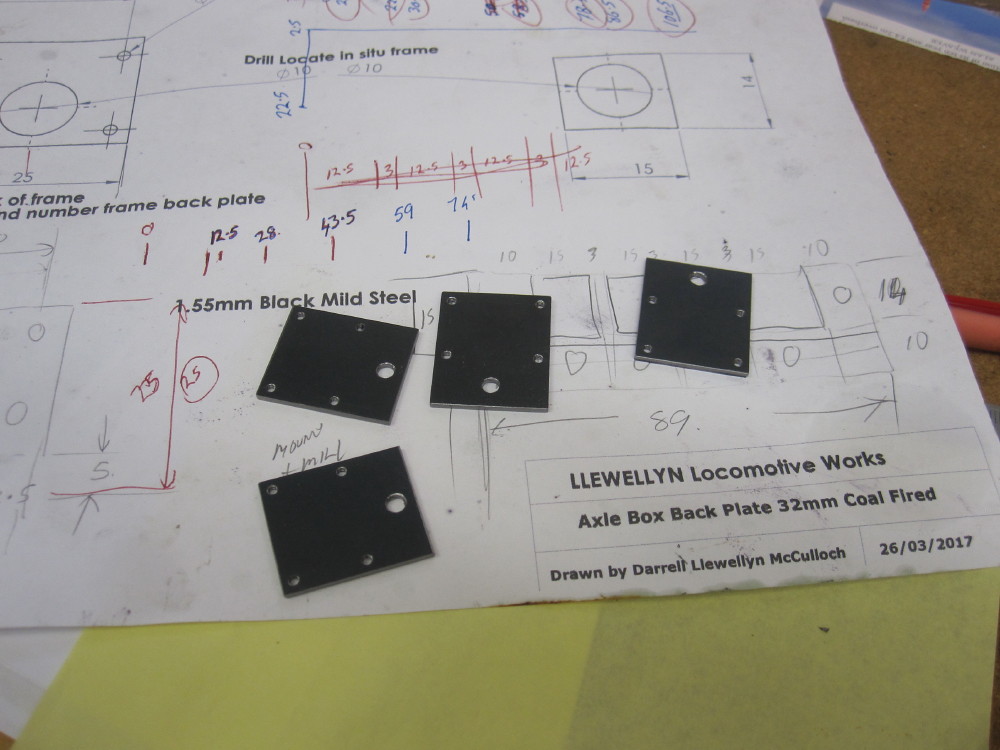

Axle box backing pieces for the 32mm loco as per the article in AME mag. The excess material below is for an M3 alignment screw for holding in place for silver brazing, then drilling and bushes fitted but those next steep will have to wait till I get back from the UK later this month. On the big bird Wednesday morning.

|

|

|

|

Post by Oily Rag on Apr 30, 2017 22:26:28 GMT

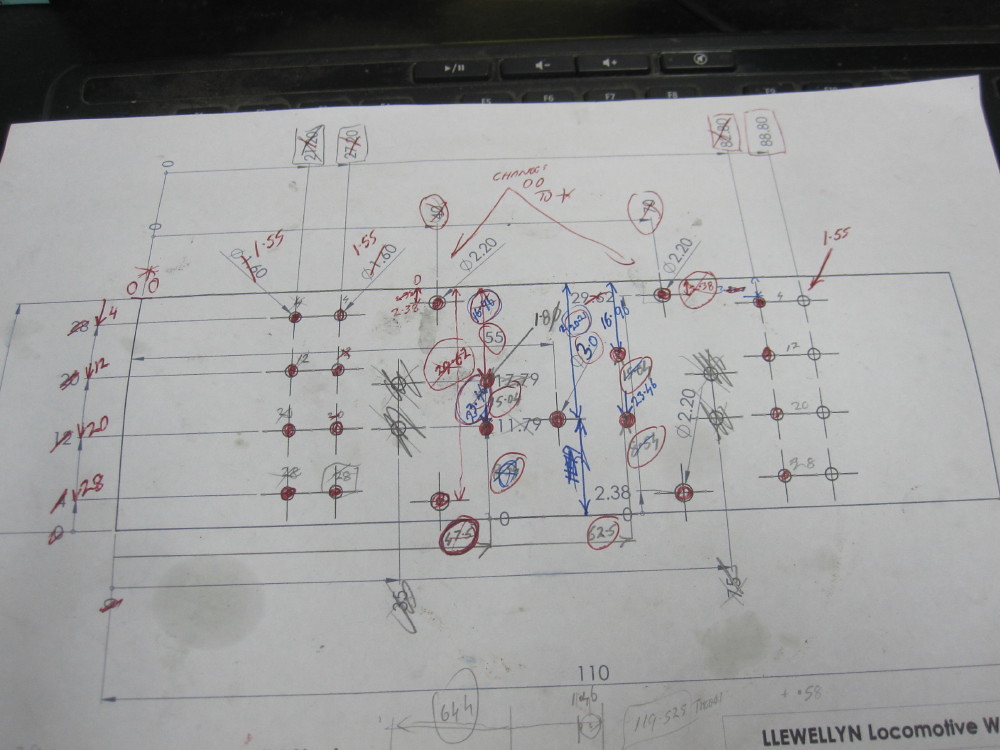

Back home from the UK, Bespoked (Bristol) was successful, A Blue for Technical Excellence and runner up by one vote in the Peers Award. :-) Visited the Ffestinoig, Welshpool and Llanfair (first time) and the Blue Bell. Started to feel better now from the ubiquitous international airliner head cold. I got some SM32 track and some Roundhouse couplers which I decided I thought would look much better if I milled the back flat so they fitted snuggly onto the buffer beam and use 10BA bolts to be fitted as studs. Cut out some 1.55m black for the buffer beams and mounted to the alloy square section and set forth with the DRO on the mill drill. Make a split bush to hold the brass square for the cutting and taping the brass frame stretchers. The crew went to the erection bay to have a quick trail mock up and they seem pleased. However one of them is always pensive! I am now off to tidy up the master set of drawings with corrections to the origin point of my dimensions and to reflect the roundhouse couplers. Next week I am back at the Rosewood Railway to start cutting the tubes and flues out of #720's boiler. Garden rail to 12" to the foot scale each week. (the 5" locos are on hold till the garden railway is up and running)

|

|

|

|

Post by Oily Rag on May 3, 2017 21:47:19 GMT

I am oily because I am excited ;-)

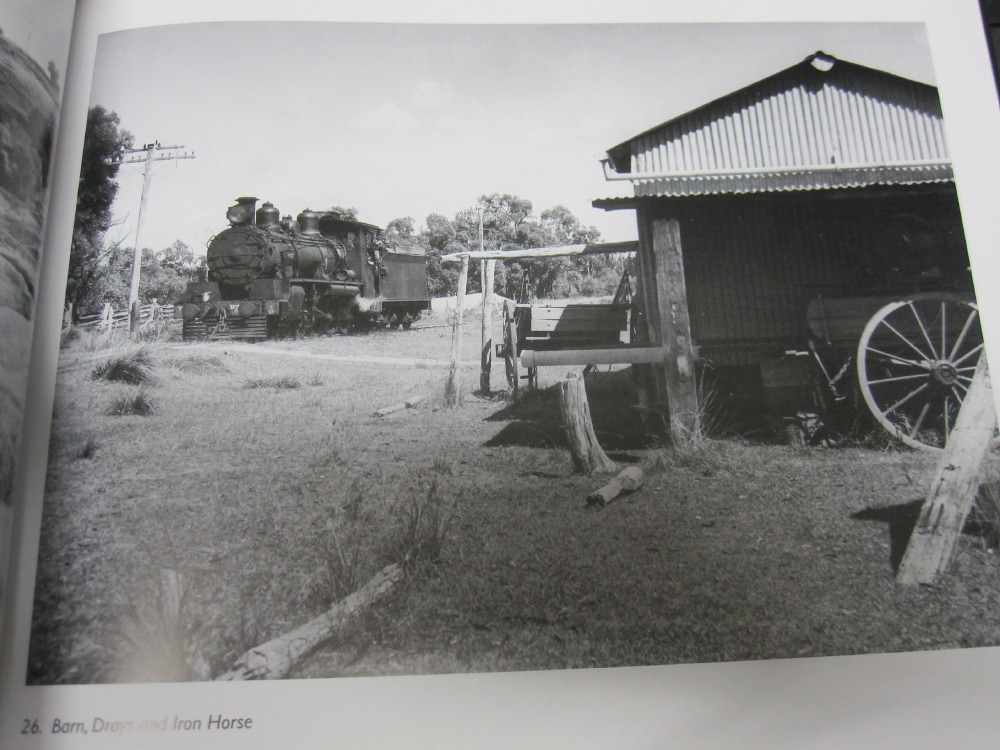

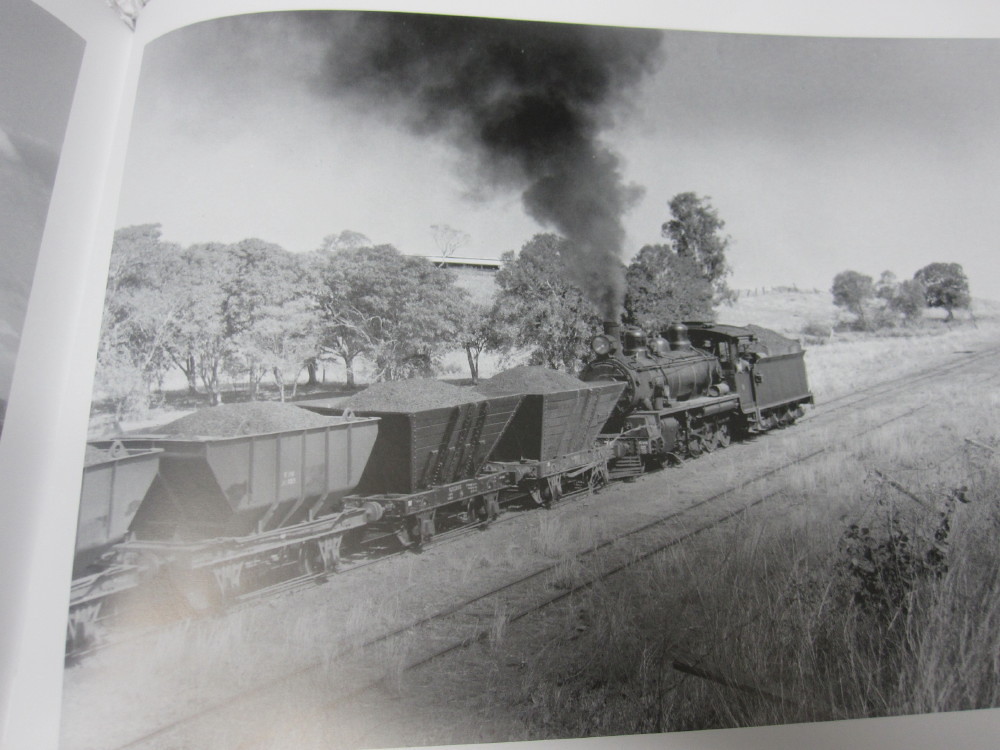

“This was the Railway” Honouring the work of Eric Margraff. The public release of this quality hard cover book is this weekend at the AMRA model train show.

In the 1960’s Eric travelled SE Qld on his 1954 350 AJS motorcycle to capture the essence and emotion of the last decade of regular steam operations. His skill and dedicated use of his 120mm film camera created these unique images. Eric also developed the negatives himself. The quality composition and details of Eric’s images are stunning gems that lure you into a detailed and prolonged visual appreciation. All but a couple of these images have never been reproduced before.

Eric has generously made these images available to the Rosewood Railway to assist in its effort to preserve some of this history.

Call in to the ARHSQD Rosewood Railway stand this weekend for your copy. $85.00

one of favourites  and another one that gets me because this is now the yard, station and sheds of the Rosewood Railway

|

|