|

|

Post by ejparrott on Jul 26, 2015 9:27:21 GMT

Hi guys. Just joined and this is my first post. An update for yesterday really. Like many of you my model engineering hasn't happened much recently due to real life getting in the way. Worked all day yesterday on rebuilding a Porsche 915 gearbox as part of a restoration we have going on at the moment. During my lunch I stopped to refit the engine control unit to my track day car after sending it away to be mapped this week. Hoping to get in my shed/workshop this week. Nets is in need of some work to get her through a boiler test. Then you never know I could actually get back to building the simplex. I was going to add a photo, but apparently the forum has exceeded its limit? You need to host the photo on a site like photobucket, tinypics or Flickr, then link the URL to here...there's a thread about it somewhere. |

|

jma1009

Elder Statesman

Posts: 5,918

|

Post by jma1009 on Jul 26, 2015 9:33:48 GMT

thanks Shawki Norman Roger and others via email and PMs re the antelope accident the other evening.

Digger it's my 5"g GWR 0-6-0 Armstrong Standard Goods that the antelope attacked. the only damage seems to be a large dent in the cab roof of the all silver soldered 1/16" thick steel cab. not quite sure how to remove the dent without caused damage to the GWR paintwork.

yesterday spent prepping the kitchen walls etc ready for repainting. and today it's too gloomy weather wise to do the painting!

cheers,

julian

|

|

|

|

Post by Jim on Jul 26, 2015 10:37:14 GMT

I was going to add a photo, but apparently the forum has exceeded its limit? There's no problem with photos if you use a site such as Photobucket, it's one of a few, but it allows you to post photos here without any problems. You might like to check out: modeleng.proboards.com/thread/3373/posting-photosJim |

|

|

|

Post by Deleted on Jul 26, 2015 10:42:42 GMT

Today I have managed to get myself right to the top of "she who must be obeyed's" good book, spent 3 hours pruning, digging over, weeding, hoeing and mowing before it started to persist it down, made her a full English breakfast complete with fried bread all served at the table (rather than on the knees in front of the telly). Now all I have to do is time it right before asking if it is alright to spend a few quid on a Tormach CNC mill. Not sure whether to do the ironing first though?

|

|

|

|

Post by GeorgeRay on Jul 26, 2015 14:56:43 GMT

Friday and yesterday I spent making a couple of trays to fit to our garden swing seat to enable our cups of tea to remain stationary while the swing moves to and fro. My camera stopped talking to the PC so had to resolve that problem before I could post this.  After that I bored out several of the aluminium lampshades for the church to enable low energy light bulbs to be fitted. Altogether that will make about 50 that I have modified over the last three years when the funds enable the church to buy some more fittings and bulbs. The original hole was about 1 inch bore but the now fitting are just under 1 5/8". The shades are 16 gauge soft aluminium which sticks to the boring tool when machining. I have now finished the job so no more to do. Sigh of relief.  |

|

pault

Elder Statesman

Posts: 1,500

|

Post by pault on Jul 26, 2015 20:01:05 GMT

Yesterday was a work day, which involved a number of different offices, this was one looking for in intermittent fault with the Driver Vigilance Device on one of the diesels.  not a bad view from the office  Turned out it was a damaged sensor cable  Problem fixed and back in traffic  Today was a day off so went to play with smaller trains, currently I'm making a new valve liner for a black 5 so todays job was a measure up of the cylinder so the liner can be made to suite  |

|

|

|

Post by GWR 101 on Jul 27, 2015 10:15:58 GMT

Just spent over half an hour talking to a helpful chap at Precision Paints, no connection, and ordered some paint (pre 1906 GWR Green etc.) and sundries.

Now the fun begins, new territory.  Regards Paul Regards Paul |

|

|

|

Post by ejparrott on Jul 27, 2015 17:39:55 GMT

Thinks to do when bored.

#1 Draw up the buffer beams for an NGG16 in 2.5" and 7.25" Gauge.

|

|

|

|

Post by fostergp6nhp on Jul 27, 2015 17:54:14 GMT

Are we going NGG16 for a club build?  ? |

|

|

|

Post by ejparrott on Jul 27, 2015 18:19:25 GMT

lol

|

|

|

|

Post by fostergp6nhp on Jul 27, 2015 20:08:11 GMT

Is that a no? Back to the Alco then.

|

|

|

|

Post by vulcanbomber on Jul 27, 2015 20:12:03 GMT

I keep mentioning a 7 1/4 16 Phil but Ed's not totally committed to it.... At 14 1/2 feet long...

|

|

robinw

Active Member

Posts: 27

|

Post by robinw on Jul 28, 2015 6:40:56 GMT

Will this also mean that Rugby will be carrying out a 2-3 mile track extension so the club can run it? :-P A 1/3 scale NGG16 would be impressive though...

|

|

|

|

Post by ejparrott on Jul 28, 2015 8:28:51 GMT

No!!!

I've been thinking of 2.5", which would be bigger than my 3.5" Hunslet. While doing it on the CAD the conversion to 7.25" was only a few clicks of the mouse!

|

|

|

|

Post by fostergp6nhp on Jul 28, 2015 15:45:23 GMT

I keep mentioning a 7 1/4 16 Phil but Ed's not totally committed to it.... At 14 1/2 feet long... David, Ed did go a bit quiet when I mentioned the length of an NGG16 or NG15 in 7.25". |

|

|

|

Post by ejparrott on Jul 28, 2015 16:02:41 GMT

...

|

|

|

|

Post by vulcanbomber on Jul 28, 2015 18:07:05 GMT

I keep mentioning a 7 1/4 16 Phil but Ed's not totally committed to it.... At 14 1/2 feet long... David, Ed did go a bit quiet when I mentioned the length of an NGG16 or NG15 in 7.25". Still no reason to chicken out if you ask me.. |

|

|

|

Post by gingerneer on Jul 29, 2015 15:45:47 GMT

Just got back from collecting 70 lengths of rail for the

ReLaying of the club track.

|

|

|

|

Post by vulcanbomber on Jul 31, 2015 20:48:36 GMT

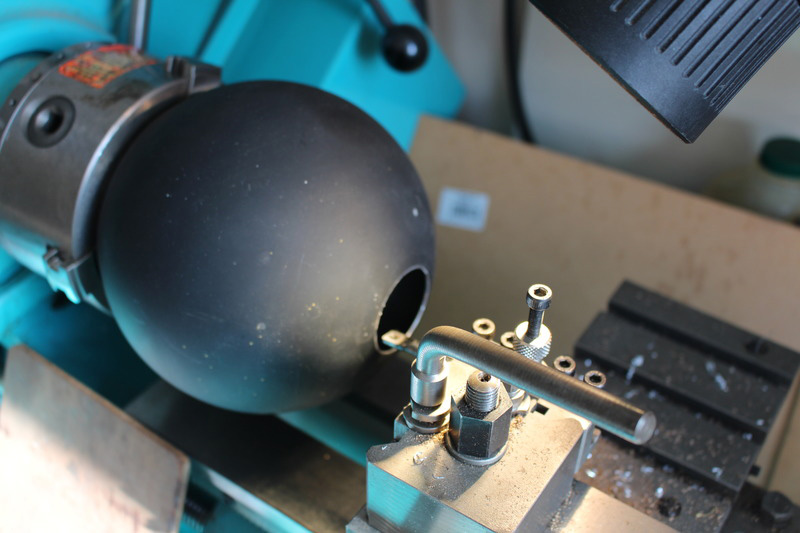

a couple of evenings this week for me has involved sorting out some brake calipers for the mother-in-laws discovery, not that exciting until 1 piston refused to come out. I thought a few of you would be interested in the fun that followed.... The easy way of doing this is to strap the caliper down on a Mill Table, naturally the mill at work was busy so off to the colchester we went. First thing i did was turn a "peg" that fits the offending piston and the drill chuck of the Lathe, hods the caliper so you have 2 hands to see where the Jaws will end up... I then wind the jaws in. Remove peg and keep nipping each jaw until its tight.. Dont go near it with a clock.  Then make a hole right through the end.  followed by a bigger hole.  And then start boring.  Eventually you'll end up with a very lopsided hole (Ed's more natural at lopsided holes than me) that you can start pealing the metal away with pliers giving you more of an idea where your going.  A bit more boring after the above picture brings you to a point where the metal will start to curl as can be seen at the bottom of the next picture.  Where you shove (with care) a flat bladed screwdriver under the thin bit of metal and the crusty bits should release and a good tug with the pliers should give you:   The same theory should work on anything that has a liner that needs removing. I hope a few find this interesting/usefull.... if not, thats 15 minutes of my life I wont get back. Cheers, David. |

|

|

|

Post by springcrocus on Jul 31, 2015 22:27:03 GMT

True, you'll never get that fifteen minutes of your life back.

However, spending it showing somebody else how to do something will never be time wasted. A good post with a point to make, unlike some of the cr@p that gets written on here.

Steve

|

|