|

|

Post by Doug on Jan 23, 2016 20:38:24 GMT

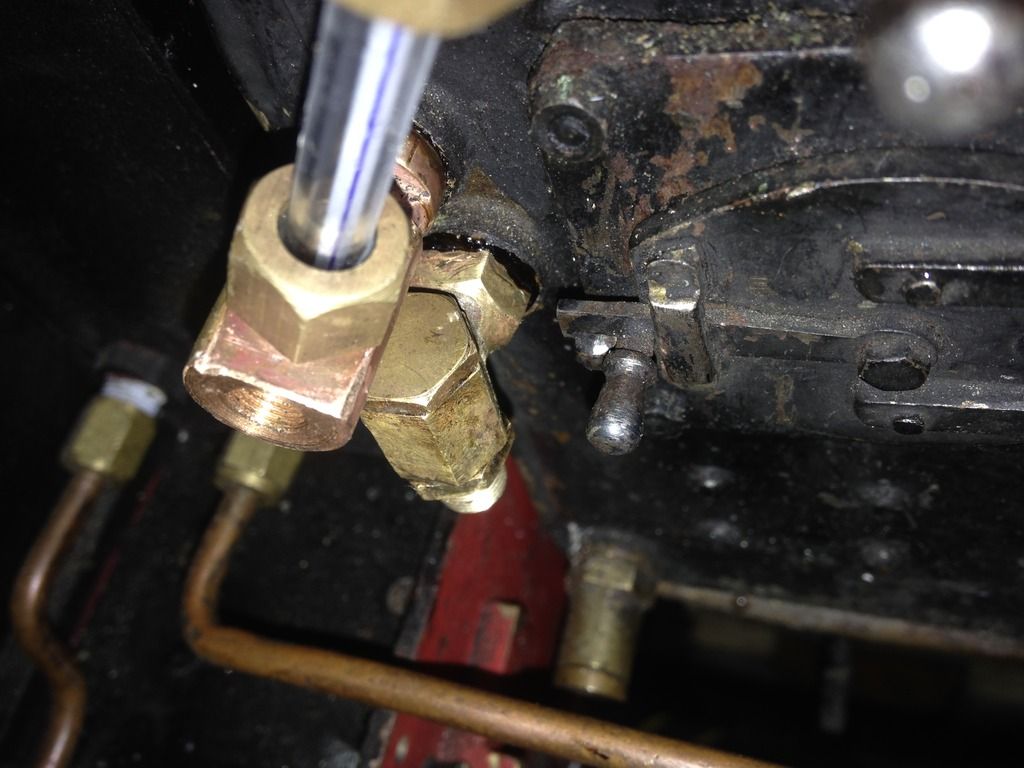

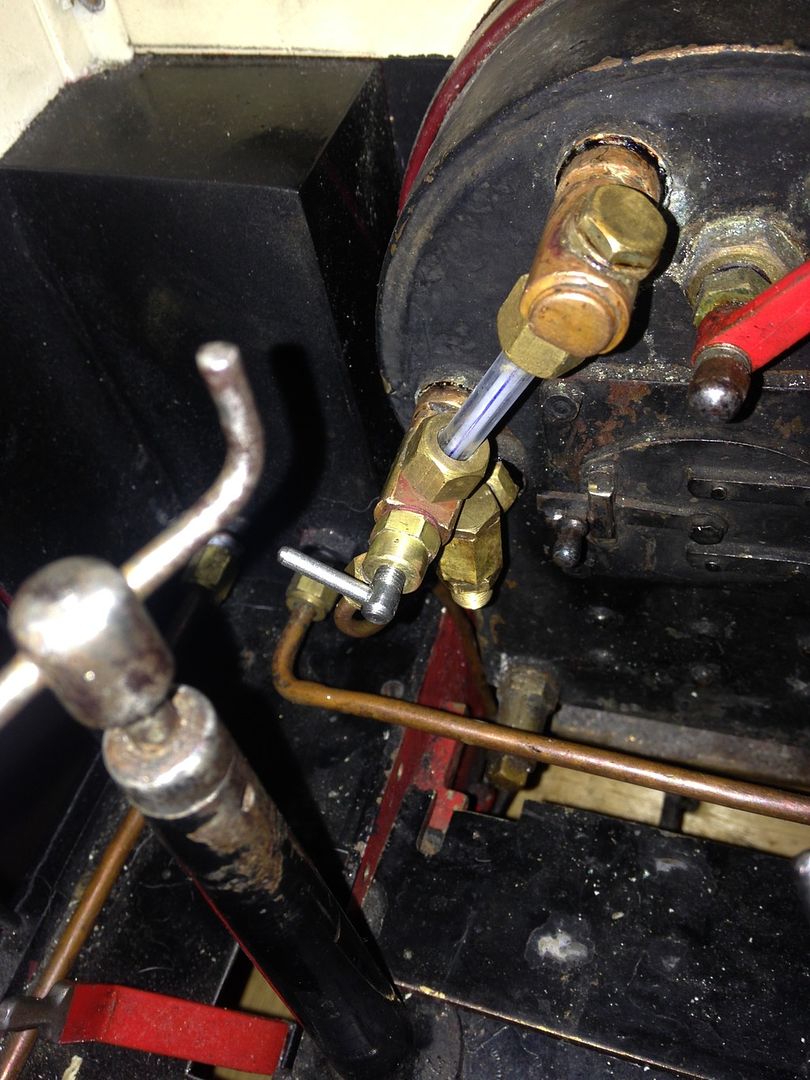

Still fixing issues nearly six years after taking ownership, I doubt I will ever really be happy but I need to get some issues resolved. things I need to fix are, injector (getting some heavy weight help with this one from Julian) sight glass blowdown (never has worked very well and leaks) cross head pump (leaks quite badly) piston rings (PTFE currently fitted and binds up under load) some paint damage (my paint job got damaged during transport to the model eng show this year) so I am going to post the work on here "just for fun" once all the issues are solved I should have a good working locomotive, I am not a big fan of the design as I can see a lot of improvements that could be done to make it run so much better but it's my great grandads Loco and I want to leave it as original as possible but running, then I can get back to my speedy. first up injector supporting modifications and sight glass blowdown. i have removed the injector valve and found the insides were a bit small so I have drilled them out to 4.5mm from 1/8" before  after  Then I had to remove the sight glass (I needed to take the injector clack off to check it anyway) So I decided to remove the old blowdown valve which does not work very well and drill it for a fitting so I can make a new valve Before  After  I had to cut the old valve off and drill the end and tap a 1/4x40 thread for a new valve think it will be much better remove able so I can service it. |

|

|

|

Post by Roger on Jan 23, 2016 23:33:58 GMT

Hi Doug,

When you say 'piston rings', I presume you mean on the main pistons and not piston valves. What sort of rings have you got? Do you think it's worth experimenting with the same arrangement I've used, ie 4 rings in one groove, large ring gaps and 'O' rings underneath? I know it sounds complicated, but it's only two tubes parted off and slit.

|

|

|

|

Post by Doug on Jan 24, 2016 0:05:05 GMT

Hi Roger yes it's the Pistons the valves are slide valves on this loco.

the Pistons have PTFE currently and there is not enough clearance so when it's hot they seal ok, when it's very hot they lock up, to be honest I am a bit fed up with them, I have replaced seals on them 4 times and it's getting a bit old. I know PTFE works but it's the expansion space that has to be right or they are going to fail. I have some proper graphite yarn seal which I have installed on speedy so I will do the same on Butch, I know it works and very well as I have previously used graphite string which worked very well till it washed out (the yarn is too big to do that) 5th time is a charm and all that :-)

|

|

|

|

Post by Shawki Shlemon on Jan 24, 2016 5:49:27 GMT

I have used PTFE in a few engines and never had any problem , the C38 has been running for over 20 years with these valve seals ( rings if yo like ) , as far as I know never been removed . The trick is the clearance . , from memory 0.008" / inch dia clearance , when cold will blow by but once warm/hot after a lap around the track all will be fine , Also PTFE is a lubricant . I have used them on piston valves and main pistons . I only use PTFE with G.M castings , I use cast iron piston rings with cast iron cylinders .

|

|

|

|

Post by Roger on Jan 24, 2016 9:41:26 GMT

Hi Doug,

Expansion is certainly very great with PTFE, and as far as I can see, you can either have a large clearance when cold, and accept that it's going t vary the pressure on the walls as the temperature changes, or have large ring gaps that never close, and deal with the sealing issues that throws up. Unfortunately I can't provide any real world anecote as to the viability of my arrangement except to say that it seals beautifully when cold, even though the ring gaps are in the region of 1mm. As Shawki and others have demonstrated, it certainly is possible to make viable PTFE rings, but the clearance is critical to avoid the issues you've encountered.

|

|

miken

Statesman

Posts: 500

|

Post by miken on Jan 24, 2016 11:39:43 GMT

Doug, The first Loco I built about 20 years ago was a Butch like yours. Same colour and LMS on the side. I learnt to drive on it and it went very well for 2 years whils I built my B1 .Its been in a box in the garage ever since and hasn't turned a wheel.

Anyway;

I agree with Roger. I used ptfe piston rings and grooved the pistons deeper to accept an O-ring under each ptfe ring. So when the ptfe ring warms up and expands, instead of expanding outwards and going tight, it goes inwards and compresses the rubber ring instead.

That is the theory and I can only say that I never had a problem.

Once I got the hang of it my Butch would do 3 hour passenger hauling sessions on Hove Park continuous track. I have a dummy coal truck/water tender end i could do 8-10 non stop laps when the track was clear. I will have to dig it out and post a pic sometime.

My loco had a hand pump in the bunker and I only ever got round to fitting one Chiverton injector which was 100% reliable. I never bothered with making the double acting axle pump. I was told at the time that it has far to high a capacity.

Mike

|

|

|

|

Post by Doug on Jan 24, 2016 20:33:25 GMT

Honestly if I didn't have two more loco's to build I would take the time to get the PTFE right however I know the graphite yarn works and I can then get back to my build. I have found the axle pump quite manageable half a lap top up usually does it every three laps or so, I found it very reliable albeit a bit underpowered (due to leaking steam chest) when it had graphite seals in the Pistons. Now I have cured all the leaks it should be able to do a bit of hauling.

|

|

|

|

Post by Doug on Feb 19, 2016 21:52:46 GMT

Empowered with a new sense of purpose thanks to Julain sending the injector back I have got the sight glass blowdown valve made.  The internals are stainless  And the completed valve   My silver soldering could go up a notch or two but least it won't leak. I just need to have a boil up now to check the injector. Then strip it all down to fix a leak on the X head pump and replace the piston rings, then I should be good for another season. |

|

|

|

Post by runner42 on Feb 20, 2016 5:05:24 GMT

Hi Doug,

a novel idea you've used to highlight the water level in the sight glass. Is it just a bit of plastic or similar material?

Brian |

|

|

|

Post by Roger on Feb 20, 2016 8:15:43 GMT

That's very neat Doug, but shouldn't it be captive? Perhaps because the design is an old one, you can do that?

|

|

|

|

Post by Doug on Feb 20, 2016 8:26:58 GMT

Hi Doug,

a novel idea you've used to highlight the water level in the sight glass. Is it just a bit of plastic or similar material?

Brian Hi Brian It is something my great grandad did it is on the inside of the glass tube and I have no idea how he did it, I still have some of the glass tube which is bare. It is not plastic. When I took it apart last time, I had a good look and it looks like paint bit it's clearly not. I will ask my Grandad if he knows what he did. all the best doug |

|

|

|

Post by Doug on Feb 20, 2016 8:37:24 GMT

That's very neat Doug, but shouldn't it be captive? Perhaps because the design is an old one, you can do that? Hi Roger none of the valves are captive this one is just a replacement of the original which leaked and had to be so tight that it had no use (needed pliers to undo) it is a 3/16"X 40tpi thread so it takes a good six+ turns to undo and in use it only needs a 1/4 turn to operate. My Speedy valves will be captive as its "my loco" this one is 55 years old so I am happy to keep it in its era. Has your boiler inspector told you you must have captive valves? It is obviously safer to have captive type valves. |

|

|

|

Post by Roger on Feb 20, 2016 8:48:06 GMT

Hi Doug,

That sounds reasonable enough. Yes, my boiler inspector says they all need to be captive, and it does make sense. Obviously it reduces the number of ways you can make them, but it's not a problem.

|

|

|

|

Post by ejparrott on Feb 20, 2016 9:27:22 GMT

I've leant my copy of the green book to our Chairman, but I don't recall it saying the *must* be captive. I will check later.

|

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,856

|

Post by uuu on Feb 20, 2016 11:57:48 GMT

Here it is:

6.5 It is recommended that screw operated valves fitted on the back head of the boiler should be of the type where the spindle cannot be screwed out. The use of non captive valve spindles or fittings should not be a reason to fail a boiler. Also check that all levers and hand-wheels are securely fitted to their respective spindles.

Wilf

|

|

|

|

Post by ejparrott on Feb 20, 2016 12:47:51 GMT

I didn't think it was mandatory, so Roger your boiler inspector doesn't have the right to DEMAND they be captive, only to RECOMMEND, and he can't fail it for it either

|

|

waggy

Statesman

Posts: 747

Member is Online

|

Post by waggy on Feb 20, 2016 13:09:49 GMT

As a boiler inspector I interpret the regulation taking into account the age of the boiler and it's fittings,ie, 'grandfather rights' apply. I would expect boiler fittings say younger than five years, to have captive spindles. I don't think it's too much to ask that a new valve should comply with our most recent test code. Again, my interpretation of the code.

What I would like to see in the code is a recommendation that a non-captive spindle should have a minimum number of turns, say four, before the thread disengages? Your thoughts appreciated here, perhaps a suggestion could be made to the boiler group that such a recommendation be incorporated in the next edition?

Waggy.

|

|

|

|

Post by ejparrott on Feb 20, 2016 13:23:37 GMT

I think the code should be changed so that old boilers have grandfather rights, but all new boilers must have captive spindles. Myself. That's what I think. I always recommend captive valve spindles, but I have no requirement to enforce them

|

|

|

|

Post by Roger on Feb 20, 2016 14:04:13 GMT

I didn't think it was mandatory, so Roger your boiler inspector doesn't have the right to DEMAND they be captive, only to RECOMMEND, and he can't fail it for it either Hi Ed, I'm sure he's not demanding it, but saying it ought to be that way. It's easy to comply with so it's not an issue for me. It's good to get clarification of the official position though. |

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,856

|

Post by uuu on Feb 20, 2016 14:40:29 GMT

Why not allow a non-compliant new boiler in an old locomotive, using the same grandfather concept?

|

|