barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Apr 27, 2021 12:14:33 GMT

Hi everybody, first of all, a reality check for me and an exercise in the noble art of compromise. As you will know I have been trying to make this engine as near to the prototype as I can (within reason) but the main frames are an area where compromises will have to be made. This photograph shows the main frames on Britannia showing the welded horn guides, spring hangers and brake hangers. This photograph shows the model mainframes and horn guides bolted to the frames. Short of scrapping the frames and starting again this is what I am stuck with. As most of this is covered by the wheels I can live with this. I am happy that I have managed to remove the 4ba and 6ba fixing bolts and add the missing rivet detail but that is as far as I will go.

These are the brake hangers, totally different to the prototype. Again, short of scrapping them and starting from scratch that is what I am stuck with. I changed the fixing bolts for round headed screws to represent the rivets but there are only four not six as in the real thing. As these are covered for the most part by the brakes, again, I can live with them.

At that point I could not resist putting the wheels in but found that they wedged onto the brake hangers. Upon checking I found that the brake hangers were all too wide so they were gingerly milled to the correct size and refitted. One of my worries has always been will the coupling rods fit so, heart in mouth, I gave the rods a trial fit and to my relief they fit perfectly and rotate without any trace of binding.  I suppose I should have known, the previous builders have been exemplary in the quality of their work, the main problem being they followed the original drawings which, in parts are a bit basic (if you are building a Britannia to the original drawings it will produce a fine locomotive, it's just that I want to test myself by including a few extra details (trying hard not to upset anybody)).

With the rods on I had a good rummage threw by box of bits for the coupling rod washers but could not find anything so assume that is as far as the previous builder had got. I had a good look at the drawings and also the Les Warnett drawings for the 9F which I assume would have similar crankpin washers and discovered that the previous builder looks to have gone his own way with some of the details. As I had to make my own anyway I decided to get as near to the real thing as possible. This is the rear right hand side washer which is retained by a taper pin on the real thing so this is my attempt to copy it. I know its on upside down, I just fitted it temporarily for the photo and didn't notice until I had wrote this update  . The pin will be cut down in size later.

The left hand washer usually has the speedo drive so has a 4 bolt fixing but 70018 Flying Dutchman was never fitted with a speedo so the washer should really be the same as the other side. As the crankpin with the 4 10ba bolt holes in it had already been pressed into the wheel and not wanting to remove it and start again I had to get a bit creative and this is what I came up with. It is based on the speedo drive dimensions and bolt pattern with the same recessed holes but round. A lot of Anglo Saxon went into this, what with braking drills etc, and this is my second attempt. I know its not right but I'm happy with the finished result.

Next will be the two front washers which are totally different to any of the drawings to I will have to get a bit creative again.

All the best

Mike

|

|

|

|

Post by David on Apr 27, 2021 22:31:57 GMT

Can't see how making a better model is going to upset anyone! It's looking great.

It is a frustration trying to bring a fine-scale mindset to these locos but you and Roger are showing whats possible if you want it bad enough. As you've seen many of us are content to follow the plans we have and hope they result in a working loco.

My running loco isn't even a model of a real one and that took some getting used to but after a while you just don't worry about it.

|

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on May 1, 2021 9:57:11 GMT

Hi Everybody, here are the front crank pin washers, two the same this time for a change. An interesting turning exercise (at least for me) in silver steel. Once I managed to work out what the previous builder was trying to do (and managed to read the drawing correctly).

This is what it looks like fitted, sorry its upside down, the chassis is upside down in the cradle. It looks like the previous builder intended to bolt them from the back of the wheel so that is what I have done here. It is tapped 6ba and secured from the back then a 6ba nut is locked onto the bolt to hold it in place. It will also have a split pin through the bolt when the proper bolts arrive, this is just mocked up for the photo. Looking at the prototype an 8ba nut and bolt would have been more appropriate but I didn't thing it would be beefy enough for the job. Not sure where the scratch came from, I must polish that out before I finally fit them.

I think the next job will be to drill the oil holes right through to the bearings, at the minute they are just blind holes, then think about fitting the suspension.

All the best

Mike

|

|

|

|

Post by Jim on May 1, 2021 21:43:49 GMT

Beautiful craftsmanship Mike.

Jim

|

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on May 2, 2021 16:12:17 GMT

Hi everybody, a quick update from Barlow works. Today I have mostly been castelating my nuts and polishing my rods. The original rods just had a nut and split pin fastening on the coupling rods and this should really have a castelated nut on it so that has been my job for today. I have seen that some people have used a slitting saw to perform this task but I don't have one that thin so decided to use a 1.5mm carbide end mill so beloved by Roger (thanks for introducing them to us all). This is very fine and definitely a heart in mouth job for me taking very fine cuts and trying not to break the cutter. Eventually the job was done and I am quite pleased with the result. Again, apologies for the engine being upside down.

I still have the other side to do as I had to have a lie down in a darkened room after this.

All the best

Mike

|

|

don9f

Statesman

Les Warnett 9F, Martin Evans “Jinty”, a part built “Austin 7” and now a part built Springbok B1.

Les Warnett 9F, Martin Evans “Jinty”, a part built “Austin 7” and now a part built Springbok B1.

Posts: 961

|

Post by don9f on May 2, 2021 17:03:56 GMT

Hi Mike, your rods look very well made and I also love the attention to detail and how you have crafted your nuts! The problem with small split pins like that is that when cleaning, they can easily get caught in the cloth/rag and the tails get bent.

Good job you're not building a 9F, you'd have to have a week in your darkened room!

Cheers Don

|

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on May 2, 2021 17:40:06 GMT

I can’t claim any credit for the rods, they were made by the previous owner and very nicely done too. I know what you mean about split pins, they also find finger ends quite easily as well. As for building a 9F, I would love too, but don’t hold your breath.😏

Mike

|

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on May 7, 2021 17:17:54 GMT

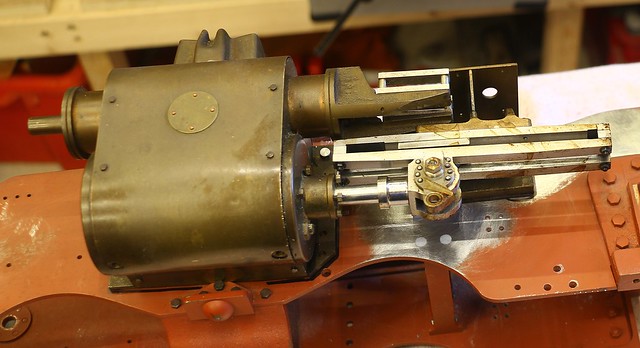

Hi Everybody. One last mock up photo with the coupling rods and this time with the connecting rod and return crank, all suitably polished up and looking pretty. Yet again everything is upside down in the cradle because the wheels are not fixed in place yet. With the rods completed they have now been put away for the time being and the wheels removed as I reasoned that I should really see about fitting the cylinders, slide bar bracket and expansion link bracket first as they will be easier to fit before I fit the wheels ( is that indeed correct and the recommended way to do it).

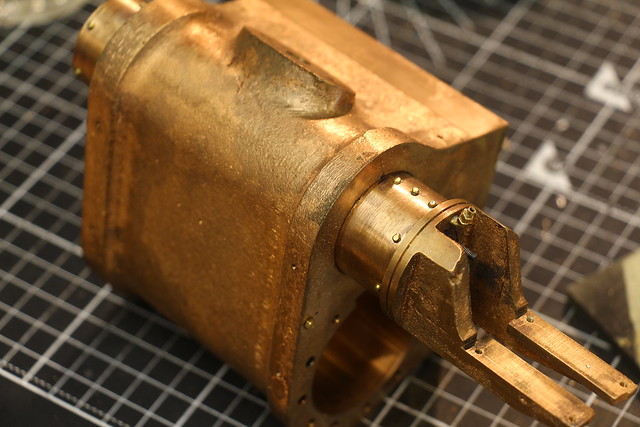

The cylinders have been completed by the previous owner and I assume build to the drawings like everything else. This voyage of discovery was what I found when I stripped it all down and raised a few questions. I think the cylinders may be cast in gunmetal (I have never come across gunmetal), they are an oringey yellow colour a bit redder than brass and the piston seems to be made of the same material and is a very good sliding fit in the bore.

IMG_3033 IMG_3033 by Michael Cawthorne, on Flickr

The bobbin (I think that is the right term) may be made from stainless.

This is all completely new to me and is definitely a step further than I have ever been before. The questions I have are these. There are no piston rings in the piston, should I fit something like O rings or a PTFE ring to make a better seal. The bobbin is in one piece, the ones I have seen on this thread usually have some kind of sealing ring on them. Again it is a good sliding fit in the bore, what would be the best plan for this part. When I fit the backing plate will I require a gasket between the cylinder and the plate and if so, what material is best suited, and finally the piston rod gland is a sliding fit on the rod but is made in two pieces, am I correct to think this is so an O ring can be fitted for a better seal. That is all I can think about for the minute but I'm sure there will be other questions, as I said I'm a complete newbie to all of this. I hope you can give me some input into the best way forward, I would like to make the cylinders as robust and trouble free as I can.

All the best

Mike

|

|

don9f

Statesman

Les Warnett 9F, Martin Evans “Jinty”, a part built “Austin 7” and now a part built Springbok B1.

Les Warnett 9F, Martin Evans “Jinty”, a part built “Austin 7” and now a part built Springbok B1.

Posts: 961

|

Post by don9f on May 7, 2021 22:52:52 GMT

Hi Mike, I’ll give you my thoughts on your questions:-

Gunmetal is an alloy of predominantly copper & tin and is extremely resistant to corrosion and a very good bearing material (also very expensive these days)!

Gunmetal cylinders seem to be quite happy with gunmetal pistons in our models.

I’ve only got the Jinty with gunmetal cylinders/pistons and it uses traditional 3/16” square graphited packing, tightly packed into 3/16” square grooves, however many people advocate and successfully use o rings as a modern alternative. Presumably wherever the ‘rings” would fit, they don’t have to cross the steam ports at the cylinder ends?

I’m not sure about stainless valve bobbins working in gunmetal bores, I have no experience of that combination but again, many people don’t have any rings on these, just relying on a good fit. The valve heads do have to cross the ports, so any rings if fitted, have to accomodate this.

On the Warnett 9F, there is a 1/32” gasket between the cylinder block and it’s backplate, but there is no gasket between the backplate and the frame. This is as per drawing and is taken into account to locate the centreline of the cylinder bore in the right place to line up with everything else that matters....like slidebars, main crankpins etc....what do the Perrier drawings show in this respect? I think Warnett described it as being a heat insulator, probably to keep the cylinders hot and is just normal gasket material (the early model designers often referred to “Hallite”, but don’t know if that’s still around these days).

Warnett specified ptfe seals around the 9F piston rods, but that didn’t work well for me and it wasn't long before I modified the arrangement to use traditional graphited packing. Since doing that a long time ago, they’ve never given any trouble. I’m sure an o ring would work here, but the problem would be having to take the crosshead off to do a replacement if ever needed! That was the problem with those ptfe seals, but now I could repack the glands easily if I ever have to.

Hope this helps you a bit! Let me know if you need any further assistance.

Cheers Don

|

|

oldnorton

Statesman

5" gauge LMS enthusiast

5" gauge LMS enthusiast

Posts: 721

|

Post by oldnorton on May 8, 2021 10:16:57 GMT

Hi Mike

Very good comment and advice from Don.

I have thought about the subject of sealing small pistons quite a lot. I will give you my understanding for you to add to the pot of musings, or reject as you see fit.

Sealing main pistons is the easy part. Old fashioned packing worked for many people in the good old days, it probably benefits from being replaced every few years. O-rings in smooth bores work and seem to last better than one might think, but probably not best for extended use. Cast iron rings are effective sealing devices, last for ever, will be fine in bronze bores despite some people's concerns if they are kept oiled. Will be difficult to make and the cold turning method is probably the most reliable precision method. Finally, PTFE rings sitting on o-rings are the 'new' preferred method. Self lubricating if the bore runs short of oil accidentally, o-rings overcome all the PTFE expansion and sealing issues.

Sealing the valve bobbins is the hard part. Older designs just ran solid bobbin heads, and this is probably as good as anything is the fits are half a thou and there is always oil in there. Thin, deep groves in theory can help reduce any tiny blow by. You cannot use anything than might catch on the transfer ports and any other steam passage. That's why only wide PTFE heads are an option. Cast iron rings have been used, but again they need to be so good at this size and the ports still need to be friendly not to catch the ring edges. I don't think Cluperts are an answer in the valves.

If you are going to run the engine just a few times a year then solid bobbins and o-rings makes life easy. If it is going to be a hard working passenger hauler (unlikely perhaps) then proper rings.

Norm

|

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on May 8, 2021 18:06:44 GMT

Thanks for the reply Norman, a bit more research to do yet before I decide what to do. I am hoping to run the engine quite a bit when completed and do quite a bit of passenger hauling as well.

All the best

Mike

|

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Aug 19, 2021 14:56:02 GMT

Hi Everybody. I can't believe my last post was at the beginning of May. I had to go back 6 pages to find my thread. Just to prove I have not been idle these past few months here are a couple of updates, again trying to make the finished model look something like the real thing. This is what we started with as made by the previous owners. Perfectly serviceable and made exactly to the drawing but lacking a lot of detail from the prototype.

The first thing I added was the rivet detail on the piston valve cladding and the oil feed to the bearing ready for a dummy oil pipe.

The other side was detailed just the same and the end cover had the fixing bolts fitted as per the prototype.

I looked at the front and back cylinder covers and their cover plates next. The holes in the cover plates as they were fitted are totally wrong, the fixing bolts being in the wrong place and much to big. I started by filling and sanding smooth the existing covers then I drilled the holes for the proper fixing bolts and transferred them through into the cylinder covers. They were then drilled and tapped for an 8ba fixing screw with a 10ba head for the fixing bolts.

The cylinder relief valves were then fitted, again dummies, from Adams range of castings. The springs were made from nickel silver wire so they look like steel but won't rust.

Finally, here are the valves assembled on the cylinder covers, the end covers are cut out to go over the valves like the prototype and will be held on with the 4 bolts like they should be.

All these details will then be taken off and put safely somewhere (for me to misplace later) to be assembled later as it nears completion. I think the next thing will be some trial fitting of the cylinders and brackets to the frames.

All the best

Mike

|

|

|

|

Post by Deleted on Aug 19, 2021 15:07:47 GMT

Great work Mike, I love the attention to detail...top job...

Pete

|

|

|

|

Post by terrier060 on Aug 19, 2021 18:33:29 GMT

Lovely work - it's keeping it all clean that worries me with my Terriers!

|

|

samc88

Active Member

Posts: 43

|

Post by samc88 on Aug 22, 2021 15:38:52 GMT

Just read through this thread,loving the attention to detail that you're putting into this. Should be a fine looking model when you've finished

|

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Aug 24, 2021 14:07:38 GMT

Steve (Springcrocus)and Jim, I've sent you a PM.

Mike

|

|

|

|

Post by steamralph on Sept 29, 2021 19:38:08 GMT

Hello everyone, my name is Ralph and I come from Germany. Since today I am registered in the forum because I found this article about the conversion of the Britannia. I'm doing exactly the same thing right now and facing the same challenges. In the next few days I will upload pictures of my Britannia here that show the conversion. I thought I was the only crazy person who would like to build a detailed model from a Winson kit ...

|

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,990

|

Post by JonL on Sept 29, 2021 20:26:45 GMT

Hello everyone, my name is Ralph and I come from Germany. Since today I am registered in the forum because I found this article about the conversion of the Britannia. I'm doing exactly the same thing right now and facing the same challenges. In the next few days I will upload pictures of my Britannia here that show the conversion. I thought I was the only crazy person who would like to build a detailed model from a Winson kit ... That sounds great Ralph; I think that's important enough to justify its own thread in General Chat. I look forward to seeing it. |

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Sept 29, 2021 22:25:02 GMT

Hi Ralph, good to hear of your interest in Britannia’s. There are quite a few on this forum in various gauges, some complete and some still under construction. As Jon says have a go at your own thread in the General Chat section, we can’t have to many Britannia threads. 👍

Mike

|

|

|

|

Post by flyingfox on Sept 30, 2021 6:32:56 GMT

Greetings Ralph, you are not the only one to want to build a good model from the poor quality Winson/Modelworks offerings. you should look for "Britannia Builder" the story of John Johnson, and his rebuild.

Good luck with your build.

regards

Brian B

|

|

I suppose I should have known, the previous builders have been exemplary in the quality of their work, the main problem being they followed the original drawings which, in parts are a bit basic (if you are building a Britannia to the original drawings it will produce a fine locomotive, it's just that I want to test myself by including a few extra details (trying hard not to upset anybody)).

I suppose I should have known, the previous builders have been exemplary in the quality of their work, the main problem being they followed the original drawings which, in parts are a bit basic (if you are building a Britannia to the original drawings it will produce a fine locomotive, it's just that I want to test myself by including a few extra details (trying hard not to upset anybody)). I suppose I should have known, the previous builders have been exemplary in the quality of their work, the main problem being they followed the original drawings which, in parts are a bit basic (if you are building a Britannia to the original drawings it will produce a fine locomotive, it's just that I want to test myself by including a few extra details (trying hard not to upset anybody)).

I suppose I should have known, the previous builders have been exemplary in the quality of their work, the main problem being they followed the original drawings which, in parts are a bit basic (if you are building a Britannia to the original drawings it will produce a fine locomotive, it's just that I want to test myself by including a few extra details (trying hard not to upset anybody)). . The pin will be cut down in size later.

. The pin will be cut down in size later. . The pin will be cut down in size later.

. The pin will be cut down in size later.