|

|

Post by David on Nov 9, 2024 23:57:39 GMT

No, only one screw. I was reading 'So you want to build a live steam loco' last night and saw the author recommended 2 grub screws at 90 deg. Too late for me, the wheels are loctited on.

People down here seem to get away with a single grub screw so I'm not too worried. I am considering drilling a 1.6mm pin hole through the stop collar and into the axle and putting a dowel in there but we'll see how it goes.

|

|

|

|

Post by David on Nov 10, 2024 5:46:45 GMT

I'd redone the timing last night but it was too late to put it back together and test it.

After reading the posts telling me I was wrong about the valve cavity this morning (and I was wrong), I took the opportunity to improve things.

I took the cylinders off and measured the ports more accurately than I could in place, then checked that against the valve cavity width. The cavity was narrower than over the insides of the cylinder ports, and also not in the centre of the valve.

I tried to clean that all up with a 2mm milling cutter which also straightened the edges of a cavities quite a bit.

Yesterday when I ran it on air it was pretty good and the beat sounded ok.

Today there is so much blow-by to the exhaust I can't hear the beat and my compressor can't keep up with it!

It wants to stall when the left piston is front-dead-centre too. I guess that could be the timing is slighly off so the port isn't open when it gets there, the other side isn't giving enough power, and the wheels are not giving enough flywheel effect.

I've had to set the valves on this engine every few years so I have a fair idea how to do it.

Other than modifying the valve cavity edges, I did these things:

* Put more packing material in the piston rod and valve spindle glands.

* Rubbed all surfaces down on my belt sander. The paper is old and it wasn't powered. This means port face, valve bottom, both sides of the steam chest, and steam chest cover.

The valve faces cleaned up but the port faces didn't - only the mating surface to the steam chest around the edge cleared up. I'm wondering if the valves and port faces had come to some arrangement whereby they had worn together and now the valve face is flatter there are a lot of places air can get between the two.

I tried flooding the steam chests with oil to see if that would do anything but it didn't.

So, air is flooding into the exhaust port from somewhere. Could I have made the valve cavity too wide (even though it now matches the inside port width) or could it be a mistmatch in the valve/port face, or could I have got the timing so wrong despite doing it relatively frequently and getting it right yesterday?

|

|

|

|

Post by David on Nov 11, 2024 4:49:39 GMT

Another look at the valves seemed to show they were not flat on the bottom, so I gave them a rob on a 600 grit diamond stone. This made no difference to the blow-by. It's really gushing out the exhaust and you need to give it a LOT of air to get it started, at which point it runs like a demon and then quickly slows down as the air pressure disappears. You cannot give it a gradual start because too much air escapes before it's going and it never gets enough pressure to overcome the starting resistance.

I also advanced the timing a tiny bit and this has fixed the hesitation at the extremes of the piston stroke. It seems to be timed pretty well and runs smoothly, it just loses a lot of the air out the exhaust before it can use it.

I finally noticed one eccentric strap was loose. I tightened both and that bright a tight spot back but I assume that will wear in.

The beat is clearer now but there is still something weird happening when the left piston is approaching and at the front - a hesitation and a rush of air. I think I will make a testing inlet manifold that only lets air get to one cylinder. Then I can test both sides in isolation and see which one (or both) are allowing big gusts of air out, and when.

|

|

|

|

Post by ettingtonliam on Nov 11, 2024 8:36:59 GMT

Yes, valve faces and port faces will bed themselves into each other over time and will work even if not flat. However, if you restore the valve to flat but not the port face, they will leak! If your port face is flat round the edges but not in the middle, it needs refacing until its flat right the way across.

|

|

|

|

Post by David on Nov 11, 2024 10:07:38 GMT

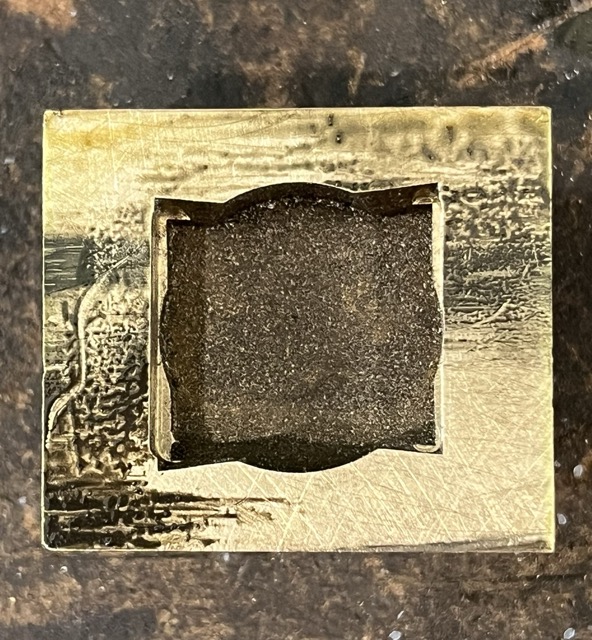

Here is a photo of one of the valves before I put it on the 600 diamond stone. I rubbed it on the oily port face as a sort of marking blue. It is obvious that one corner is high. But it also shows the cleaned up edges of the exhaust cavity. I took somewhere between 0.010 and 0.020 off each side of each valve which straightened the edges and brought them to width as per the instructions. I am going to convince myself this will lead to a crisper exhaust beat.  |

|

|

|

Sisyphean

Nov 11, 2024 11:54:14 GMT

via mobile

Post by chris vine on Nov 11, 2024 11:54:14 GMT

Hi David,

This is going to sound really stupid but:

Is it possible that the valve had gone back funny so that the steam edge of the valve is travelling beyond the start of the exhaust port?

That would let plenty of air up the chimney momentarily.

Sorry if that is an insulting suggestion! I only make it because you mention that the leak isn’t continuous, which one might expect if the faces were not flat.

Chris

|

|

|

|

Post by flyingfox on Nov 11, 2024 12:09:15 GMT

Greeting David, further to Chris's comment, is there any possibility of the valve lifting during part of its travel?

Regards

Brian B

|

|

millman

Part of the e-furniture

Posts: 324

|

Post by millman on Nov 11, 2024 15:54:03 GMT

I would imagine that whoever made the valves made a round hole, bored in lathe or perhaps slot drill in mill to remove most of the metal before using a small cutter to clean up the port edges, doesn’t explain the funny angles though, or the pitted finish without cutter marks on the bottom. I wonder if they were spark eroded?

|

|

|

|

Post by David on Nov 11, 2024 20:46:19 GMT

I agree Chris, that would result in a great deal of air out the exhaust! The valve travel & position looks good when I'm turning the wheels by hand and watching the valve move, so I don't *think* the problem is travel or timing.

I'm wondering if there is a low spot on the port face when the valve is all the way forwards. That could allow air through and even perhaps for some lift.

I am going to take the cylinder off and fly cut the port face.

|

|

|

|

Post by David on Nov 12, 2024 8:29:27 GMT

|

|

|

|

Post by David on Nov 13, 2024 11:06:27 GMT

I gave the right cylinder port face the same treatment. The loco seems to be running really well on air, possibly able to run smoothly slower than it did yesterday, but still has the exhaust hiss. The hesitation has eased a bit, but there is still a tight spot somewhere which I don't think is surprising given everything except the coupling rods is new.

I don't think I should continue on until either the hiss has gone, or someone else has a listen and look and says it's normal. It seems silly to have it stripped to this state and not get it as good as possible.

The steam chests and cylinders are swimming in oil - would that help or hinder in this situation?

|

|

|

|

Post by chris vine on Nov 13, 2024 15:58:36 GMT

Hi David,

some inspector Clouseau sleuthing is called for here.

Can you connect the airline but only put a couple of pounds pressure on and then turn slowly by hand and watch, listen and feel.

I think you will find some clues that way…

Chris

|

|

|

|

Post by David on Nov 18, 2024 9:16:38 GMT

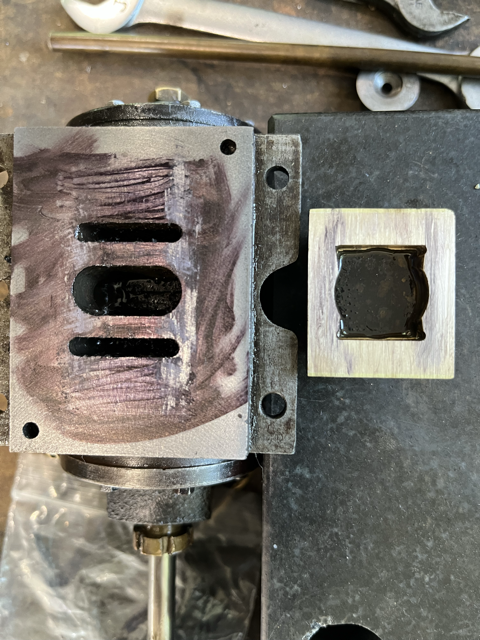

Yes Chris, good idea. Along with that my friend suggested taking off the exhaust manifold so I could feel what's coming out of each cylinder. It was quickly clear that the left hand cylinder was OK with 2 bursts of air per wheel revolution whereas the right hand one generally didn't sound or feel right compared to the other one - sort of waffly. The photo shows the marks left from rubbing the valve against the port face and it's clear something isn't flat and it looks like the air could escape at the front and rear edges of the valve. I didn't know which bit wasn't flat so I skimmed both the valve and the port face again. I had done the port face already but it's possible I did it wrong. It seems a lot better now.  |

|

|

|

Post by chris vine on Nov 18, 2024 11:36:22 GMT

Great news!!

Onward and upward...

Chris.

|

|