|

|

Post by ejparrott on Oct 8, 2014 9:23:11 GMT

I always use the jaws either side of the makers badge on the chuck, and with the three jaw chuck I always use the socket hole nearest the badge - this is extremely important for when using soft jaws, and it's a mindset I've built up and stick to, then I don't forget.

|

|

|

|

Post by Roger on Oct 8, 2014 9:34:23 GMT

I've never seen a boring head used like that before Jim, have you got a wider angle shot of that? What was the reasoning behind using that?

|

|

|

|

Post by Jim on Oct 8, 2014 10:51:34 GMT

Hi Roger,

In answer to your question the cutters are essentially D bits and when I first got the boring head a couple of years back I had the cutter set up as one would for a conventional boring bar. The problem of course was that the feed screw was on the opposite side to me and out of sight making it hard to take measured cuts. Then it occurred to me that with the cutter on the centre line anyway it could just as easily feed down as across and with the added advantage of having the feed screw and scale easily accessible. The method works and is accurate.

Jim.

|

|

|

|

Post by Jim on Oct 8, 2014 10:59:18 GMT

I always use the jaws either side of the makers badge on the chuck, and with the three jaw chuck I always use the socket hole nearest the badge - this is extremely important for when using soft jaws, and it's a mindset I've built up and stick to, then I don't forget. That's a good point Ed regarding the three jaw chuck. I filed a light groove on the face of the No1 jaw and use it a guide to centre pop any job that I may need to remove from the chuck part way through the job. Using the centre pop to line up with the groove I can return the job to the chuck to the same settings. Jim PS: You made curious Ed so I went out to the workshop the check my 4 jaw chuck and 'Yes' it has a maker's stamp and the jaws I marked are, believe it or not, either side of the maker's mark. I think I better stop sniffing that Stag Jointing paste  |

|

|

|

Post by Roger on Oct 8, 2014 11:44:56 GMT

So the boring head is in the tailstock then, that's what I'd assumed. I'm surprised you find that satisfactory, the tailstock isn't that rigid and there's always some play in it unless you partially lock it. Maybe that's what you do.

It does beg the question as to why you don't put the 'D' bits in the toolpost though? That would make for a much more rigid setup. Some of the quick change toolholders I've got have a shallow vee in the bottom of them for that purpose although you can still use them with the flat bottomed type.

I've made a number of square mild steel holders for round bits of verious sizes. Just a piece of square bar, drilled down the middle and slit along the side. There's even one that's 1/8" to hold two flure carbide slot drills used in PCB production, they make amazing micro boring bars.

I'm not a fan of using two unmoved jaws of a 4 jaw for reference they don't repeat well enough for my liking and there's a lot of fiddling about with a clock on the face of the part trying to get it to sit dead true on the jaws.

|

|

|

|

Post by ejparrott on Oct 8, 2014 11:53:11 GMT

Its not about using 'two unmoved jaws for reference', its about getting the part back in close to true quickly. Believe me, it works and it saves a lot of time. It's very rare I use 3-jaw's, The big lathe and all the vertical borers have 4-jaw independents, and I use them every day.

|

|

|

|

Post by Jim on Oct 8, 2014 12:14:42 GMT

Hi Roger,

Yes I do partially lock the tail stock to remove any unwanted movement and that way the set up works very well indeed. So far I've done four of the bearings without any drama and to a nice slide in fit.

As Ed says the purpose of the marked jaws is to make setting up the next part as close to true as possible. Inevitably some minor adjustments are needed to get the final setting correct but they are minor. When the work is complete it's the two marked jaws that I ease off to remove the work piece.

Jim.

|

|

|

|

Post by Roger on Oct 8, 2014 13:34:23 GMT

Fair enough if you can adjust it. I was more thinking about the situations where there's no reference to clock and you rely on it being right. I'd forgotten that you already had a hole in there.

I rarely use the 4-jaw now I've got the Grip true, but that's only good for round bar. I clock up pretty much everything because it takes to little time with it always being close in the first place.

|

|

|

|

Post by GWR 101 on Oct 8, 2014 16:24:34 GMT

Hi Jim, looking really good and very neat. Just wondered if you have decided on a braking system yet. Regards Paul

|

|

|

|

Post by Jim on Oct 8, 2014 21:00:49 GMT

Thanks Paul I'll be using the braking system as drawn. I might have sent you a PM some time back with the drawings, I can't recall now.

I must say your disc braking system is looking pretty good judging from the photos you sent me.

Jim.

|

|

|

|

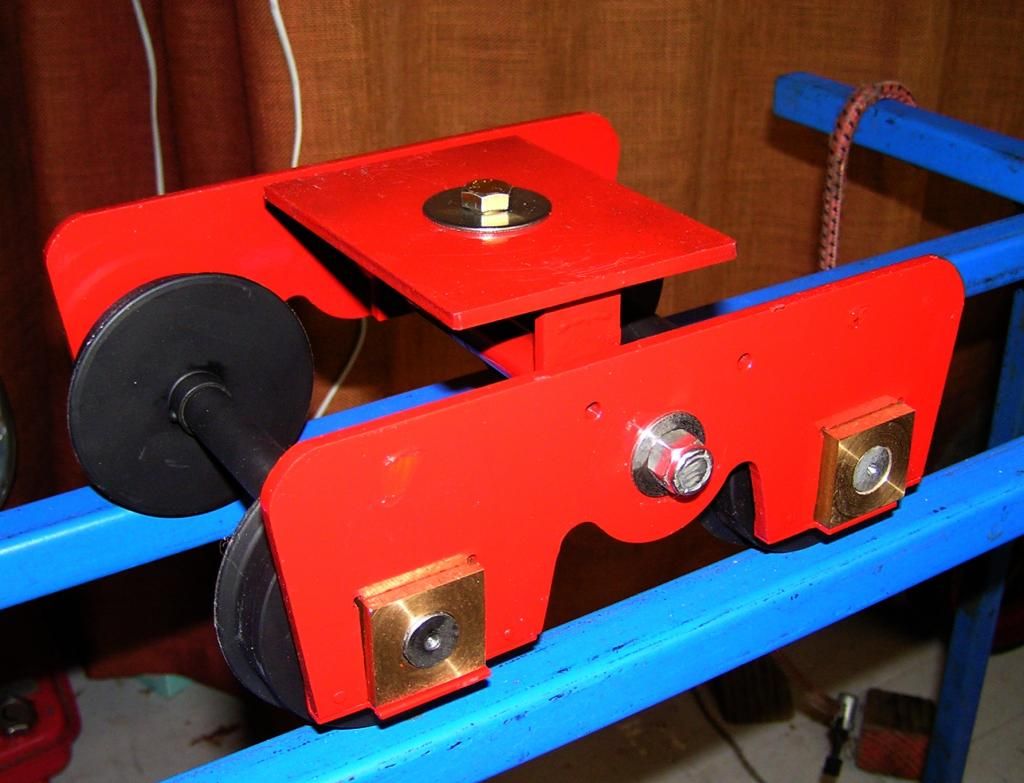

Post by Jim on Oct 20, 2014 10:44:36 GMT

Just a brief up date. As I can't get the boiler to our club inspector until the first of next month I decided to push on and complete the bogies for the driving trolley. These are purely utilitarian bogies designed to carry me plus a passenger. When complete the bogies will be hidden from view by the foot boards which is no bad thing as I intend the actual body of the trolley to resemble a 4 wheel CCT which fits the period of my 2 coaches. The bogie looking a garish sitting on blue track, will be braked. Jim  |

|

|

|

Post by arch1947 on Oct 20, 2014 21:31:46 GMT

Hi Jim, I think we both have the same AME article on riding cars, mine looks remarkably similar and works fine. I hinged the footplates similar to one I saw on the Station Road website, makes it a bit more compact in the back of the ute and do hide the bogies when down. I put brakes on the rear bogie and they work OK.

Cheers,

Arch

|

|

|

|

Post by Jim on Oct 20, 2014 23:17:01 GMT

G'day Arch, Thanks for that information about the braked bogie. I was tossing up as to whether it would be better at the front or the rear. I'll now put the un-braked bogie at the front. According to the plans the front bogie also has the ability to rock slightly from side to side to ensure that all wheels are in contact with the track at all times. You're right about the plans, they are Ross Bishop's and published in AME Sept/Oct 1991. With luck I should get started on brazing up the under frame today, I have a good stock of soothing ales too just in case things start to go pear shaped.  Jim |

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Oct 21, 2014 1:00:50 GMT

Jim and Arch

I differ regarding bogies and brake location.

Ask yourselves the question, where will the weight always be? Where will the weight be when you are driving solo or with the grandkids?

If it is your driving truck it will be your weight at the front always so this bogie should not rock. Equally the bogie with the brakes should be on the front, weight will transfer to it when braking anyway.

It would pay to look up the AALS standards.

Regards

Ian

|

|

|

|

Post by Jim on Oct 21, 2014 2:40:17 GMT

Thanks for your comments and observations Ian, the points you've raised will be taken into consideration.

Jim

|

|

|

|

Post by ejparrott on Oct 21, 2014 8:04:39 GMT

I's just brake both!

I've got a new bogie well wagon driving truck for the 5"...I don't like the bogie design which is similar to that we have at the club with split axles, and the PO had a water hydraulic brake system combined with a hand pump for his engine...worked well when you got it sorted but had to be refilled and bled every use. I'll be ditching the bogies and the brakes, fitting it with new bogies suitable for GL5 use, and fitting both bogies with vacuum brakes.

|

|

|

|

Post by Jim on Oct 21, 2014 10:05:14 GMT

I hadn't looked at the GL5 site in recent times Ed. I must go and recheck.

I must admit the thought of having both bogies braked is an attractive concept that had drifted across my mind.

I've been to Gilling, sadly on a non running day though there were a couple of locos being given a run following maintenance work. A very impressive place I must say.

The club I belong to is very much into scale rolling stock as you might have noticed from a couple of photos I posted on the GL5 site of a member's Hereford steers he created for his scale cattle van. Amazing work.

Jim

|

|

|

|

Post by Jim on Nov 4, 2014 10:03:07 GMT

Well today marks a big milestone reached. With a fellow modeller I drove over to Orange for our club boiler inspector to check and test Boadicea's boiler and thankfully it passed with flying colours while happily maintaining 200 psi for the required time They say pride goes before the fall and I was quickly brought down to earth, literally, when we headed to the club track to give the driving trolley a run. With a gentle push it rolled off down the line and rolled and rolled and rolled so I took off to catch it forgetting the elevated line from the loading bay. The last view I had of my trolley was it happily rounding a distant bend as I went face first into the ballast!  Fortunately no damage to me other than my dignity. My mate retrieved the trolley and managed to stifle a chuckle. Just for interests sake the round trip involved 605kms through the quiet rural country side of the western slopes. Boadicea will have a well traveled boiler by the time I get round to the steam test. Jim |

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Nov 4, 2014 10:26:15 GMT

excellent news jim! very well done!wont be long now till a steam up i expect!

cheers,

julian

|

|

|

|

Post by Jim on Nov 4, 2014 10:44:40 GMT

Thanks Julian, I must say I found your series of photos taken as you did your boiler invaluable in getting a clear understanding of what to watch for when silver brazing a boiler. As they say a picture is worth a thousand words.

Jim

|

|