|

|

Post by runner42 on Sept 8, 2014 6:48:20 GMT

Hi Jim,

what pressure will the tender pump produce assuming it's easily removed. It's a good idea to see if the boiler will hold the twice X WP before you submit it to the boiler inspector given that you have a 300Kms journey.

Brian

|

|

|

|

Post by Jim on Sept 8, 2014 8:24:03 GMT

I'm actually thinking of 'borrowing' the tender pump from my Burrell to use in a making up a pressure testing set up. I'm not so much interested in getting the boiler to 2 X WP as slowly increasing the pressure so as allow the boiler to 'adjust' to the stresses as the pressure increases. Along the way I'm sure any hidden leaks will make their location known.

Jim

|

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Sept 8, 2014 10:16:28 GMT

Jim

Again I am no expert just an engineer. I would pump the boiler up and release the pressure a few times building up the pressure in steps to the test pressure; this will work harden the copper.

|

|

|

|

Post by Jim on Sept 8, 2014 12:49:16 GMT

Thanks Ian, work hardening was what I had in mind but the pump up and release I hadn't thought of and it makes a lot more sense. Thanks for that.

Jim

|

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Sept 9, 2014 22:55:03 GMT

hi jim,

there is a school of thought that the copper doesnt 'work harden' at 1.5 times working pressure. however i think that it does 'age harden' and repeatedly hydraulically pressurising the boiler must make it less soft after annealing plus i find that the slightest movement in the annealed soft plates at first (undetectable by eye) can cause quite a lowering of the pressure on the gauge. i tend to pump mine up with cold water then leave in the sun all day outdoors after construction. i do this quite a few times before submitting to the dreaded official test! in fact i take all my boilers along to the club for a test already pumped up with a fullsize gauge fitted.

i would very strongly recommend your own hydraulic test to the test pressure before the official test. it wont take more than a day or two to make a simple hand pump. i have a large (fullsize) gauge that i can fit direct into the boiler via a special adapter i made years ago. my own boiler test rig consists of the above gauge plus the first and only handpump i made when 16 years old (never got fitted to the loco) and a plastic ice cream tub that it sits in containing the water. when up to pressure i use an old blower valve on the supply from pump to boiler to stop any back leakage through the pump. the official test rigs are rather more elaborate, but the above is just as effective.

cheers,

julian

|

|

|

|

Post by Jim on Sept 10, 2014 1:33:27 GMT

Thanks Julian that is very good advice and I shall go ahead and make up a boiler test rig to make sure all is as good as it can be. A round trip of 600kms even if it is through the lovely western slopes is too far to go for an "oh dear!" moment.  Sadly a much respected local boiler inspector passed away just recently. He was a good friend and more than happy to assist in situations such as this. Jim. |

|

|

|

Post by Jim on Sept 30, 2014 22:50:03 GMT

School holidays, visiting grandchildren, fixing bikes, taking them to zoos and museums, getting squirted with the garden hose, "Sorry Granfer!" snigger snigger....despite all these distractions Boadicea's boiler is now tight and ready for a visit to the boiler inspector. Never thought it would happen  Jim |

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Sept 30, 2014 23:00:54 GMT

hi jim,

that is excellent news!

very well done on what is quite a huge boiler!

hope you now feel full of enthusiasm to finish the loco! as your summer approaches we have our winter to contend with!

cheers,

julian

|

|

|

|

Post by Deleted on Sept 30, 2014 23:30:33 GMT

hi jim, that is excellent news! very well done on what is quite a huge boiler! hope you now feel full of enthusiasm to finish the loco! as your summer approaches we have our winter to contend with! cheers, julian --------------------------- and with our new Road Tax laws starting as of to-day it'll be a "Winter of Discontent" as well.........How many of you ( UK people) know that from now on the next time you sell your car you can't transfer the remaining tax with it but have to apply for a re-fund ??---------and the new owner has to immediately either Tax it or declare SORN....Yes, those Brit boilers are a bit on the B-I-G side....Well done indeed matey !!----As Julian rightly says, it's a wise idea to do some preliminary testing yourself prior to the actual thing......Keep an eye on crown deflection.............TIP}--- make sure the stamped boiler ID code is clearly visible especially after all the bodywork has been attached and the loco is in running trim..... |

|

|

|

Post by Jim on Oct 1, 2014 3:12:58 GMT

Thank you Julian and Alan for your supportive comments and Julian for posting the photos of your own boiler and stages of construction. I and quite a few others found the photos and observations very helpful indeed in getting a 'feel' for what is needed technique wise when building a boiler for the first time.

Jim

|

|

|

|

Post by GWR 101 on Oct 1, 2014 7:05:22 GMT

Yes congratulations Jim, very well done I am sure all will go well with the inspector. And multi tasking as well..... Regards Paul

|

|

|

|

Post by Deleted on Oct 1, 2014 8:45:10 GMT

Great news Jim....I for one and I'm sure many others here look forward to the video of the first steam up......well done....  Pete |

|

|

|

Post by Jim on Oct 1, 2014 11:37:08 GMT

Thanks all for the kind thoughts. I spoke to Barry our club boiler inspector this afternoon who suggested I come over in the next couple of days. When I mentioned this to the controller of the calendar I was promptly reminded of a dental appointment, a family reunion (not mine) plus lots more happenings taking up most of next week. When I suggested putting all these things off for a lovely outing in the country to the boiler inspector's I was met with the start of a death stare that would burn through steel. I surrendered  but I'm still alive  Jim. |

|

|

|

Post by Deleted on Oct 1, 2014 11:52:52 GMT

Funny, isn't it ??..........All down the ages, and no matter where you go in this world of ours, no matter which Society you make contact with, the "Ladies" all have this same form of influence on their menfolk !!..............Running a close second comes the "Mother-in-Law" syndrome......................."No, you can't go hunting wild boar in the Jungle with the lads to-day.....great Family Mother is coming to visit and this hut needs a good cleaning before she arrives" must have the same crushing effect for our opposite number wearing face paint and carrying a spear as it does for us, I'd say ??----------------------------------------and with the "Family" has come the children who turn into ----- TEENAGERS ----- www.youtube.com/watch?v=ytgDuV0qOBI |

|

|

|

Post by Jim on Oct 7, 2014 4:45:37 GMT

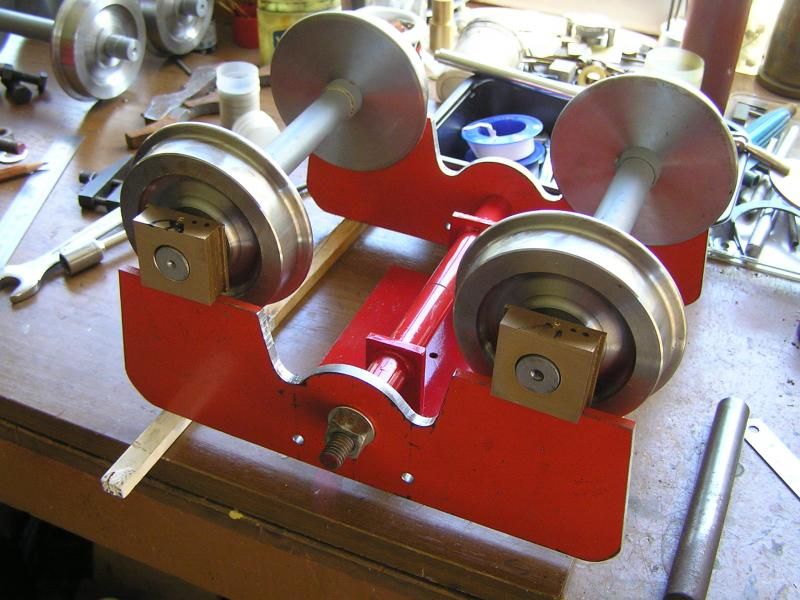

Just an update. School holidays are over ending visits from grandchildren and all sorts of associated and exhausting activity guaranteed to drive this 75 yo round the twist. Life has now returned to 'normal'  Next week should see us make the run to Orange to have the boiler officially tested all being well. In the meantime the boiler sits in its rightful place and work has progressed on the driving trolley. The photo shows the first set of bearing blocks resting on the bogie frame while waiting to have the bearing recesses bored out on the inner faces.  We're slowly getting there, Jim |

|

|

|

Post by Roger on Oct 7, 2014 5:48:00 GMT

That's a very purposeful bogie Jim, that certainly looks plenty man enough for the job.

|

|

|

|

Post by Jim on Oct 7, 2014 7:23:09 GMT

Hi Roger, The bogies and the yet to be built frames are certainly designed to carry a weight...sadly mine  As you can see the bogie frames have yet to have the recesses cut out for the bearings to fit into. The bogies are compensated rather than sprung with the trailing bogie also able to rock on a central 'Dee' shaped surface to create a 'three legged stool effect' if that makes sense. The design is by Ross Bishop and was published in Australian Model Engineer some time back. As mentioned previously I intend to model the body work on a 4 wheel BR CCT van to fit in with the two BR Mk1 coaches. There's nothing like having two or three projects running at once to keep the grey matter in a state of total confusion.  Jim |

|

|

|

Post by Roger on Oct 7, 2014 7:49:00 GMT

I'm so focused on SPEEDY that I haven't given a moment's thought to such things. I've got business, DIY, car and SPEEDY on the go at the moment and I'm in a state of meltdown trying to juggle them all. I really don't have time to work but it's got to be done I'm afraid. No more big projects when this batch are done, I need a break.

|

|

|

|

Post by ejparrott on Oct 7, 2014 9:02:03 GMT

Welcome to my world....

|

|

|

|

Post by Jim on Oct 8, 2014 8:13:05 GMT

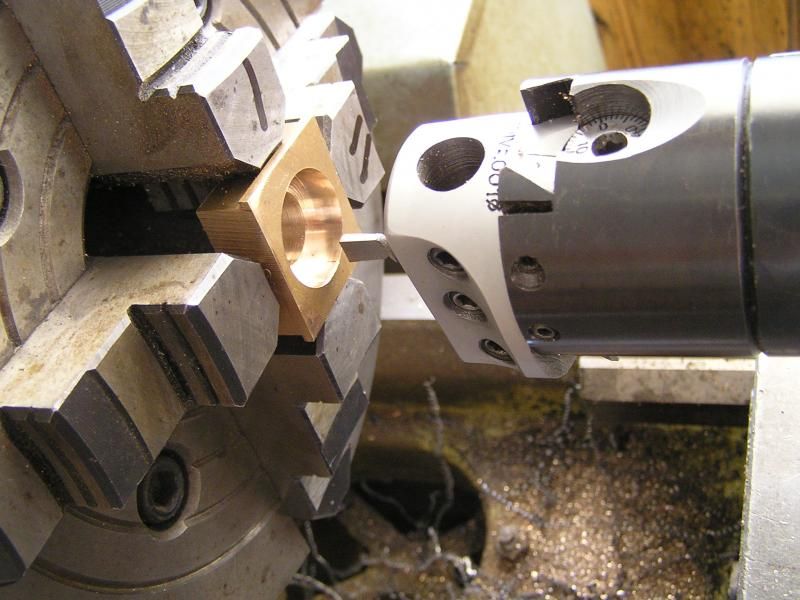

It's nice to get back to the lathe and today I've been boring out the bearing blocks to house the ball races for the axles. The first photo shows the block being centered using the mandrel which is a push fit in the hole, as a reference point. It gives a very acceptable level of accuracy for the job in hand.  With the block centered the first cut was made to the required depth ie width of the bearing plus the flange. Once satisfied the all was correct the tail stock was set to zero mm. From then on it was then a simple matter of setting the depth of cut and feeding in until the tail stock dial read O. In case anyone is wondering the jaws are marked with a felt tip pen as a aid to centering the job and to stop me getting confused as to which jaw I just adjusted.  The last picture shows the counter bore completed and ready to house the bearing.  All being well we'll head over to Orange next week to have the boiler inspector test the boiler. Jim. |

|