|

|

Post by Donald G on Nov 26, 2015 13:15:13 GMT

Julian, it would be great to read, and see pictures as you make the takes. I have part completed tanks for my Class 2 tank, but still need to actually assemble the sides and the rest together.

Donald

|

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Dec 13, 2015 21:29:23 GMT

at long last i am on the home straight with the cab steps...  as you may recall i had a big problem with the cab steps fouling the rear crankpin collars. i have also made things far more complicated because i have an aversion to cab steps being fixed to the valances. so mine are fixed to steel webbed angle and fixed by countersunk 8BA screws through the running boards. the crankpin foul was resolved by taking a 1/16" off the crankpin collars, and cutting back the original cab steps to clear, and making new cab steps out of 0.75mm steel sheet to fit on the outside. the footsteps were bashed out of the same 0.75mm sheet. in the pic, the footsteps are temporarily located with 3/64" dia brass roundhead rivets. there are no roundhead rivets on LBSCR locos, so i need to next countersink the footsteps and put the rivets in the other way round. the brass rivets are 'hard' so also need annealing, plus shortening, before rivetting the cab steps and footsteps to the old re-profiled cab steps behind. a lot of fiddly work. the countersunk heads on the outside will have to be formed with a drift as you cant get a hammer anywhere near. drilling the 3/64" dia holes through 3 pieces of plate was quite fun! one of the advantages of having the cab steps removable is that the rather intricate lining out can be easily done later on. cheers, julian |

|

|

|

Post by Deleted on Dec 13, 2015 21:41:59 GMT

those steps look great ....nice work...  Pete |

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Dec 13, 2015 21:51:10 GMT

thanks pete!

ive had a real mental block for a few weeks how to deal with these pesky cab steps! GWR cab steps are much easier!

cheers,

julian

|

|

|

|

Post by Jim on Dec 14, 2015 3:13:09 GMT

As Pete says the steps look great..well done Julian. I must admit to having mental blocks too, the current one being completing the regulator linkages, after that it'll be the cab roof. In between blocks I fiddle with this or that fitting.  Jim |

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Dec 14, 2015 22:30:39 GMT

thanks, Jim!

the cab steps are all now rivetted up and finished apart from a bit of fine tuning to the outer shape on one. there were quite a few dings whilst rivetting as needed a 3rd pair of hands, and im not very patient these days, but a thick layer of brush on cellulose grey primer has been applied to act as a filler.

the side tanks are the next job.

cheers,

julian

|

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Dec 16, 2015 22:56:04 GMT

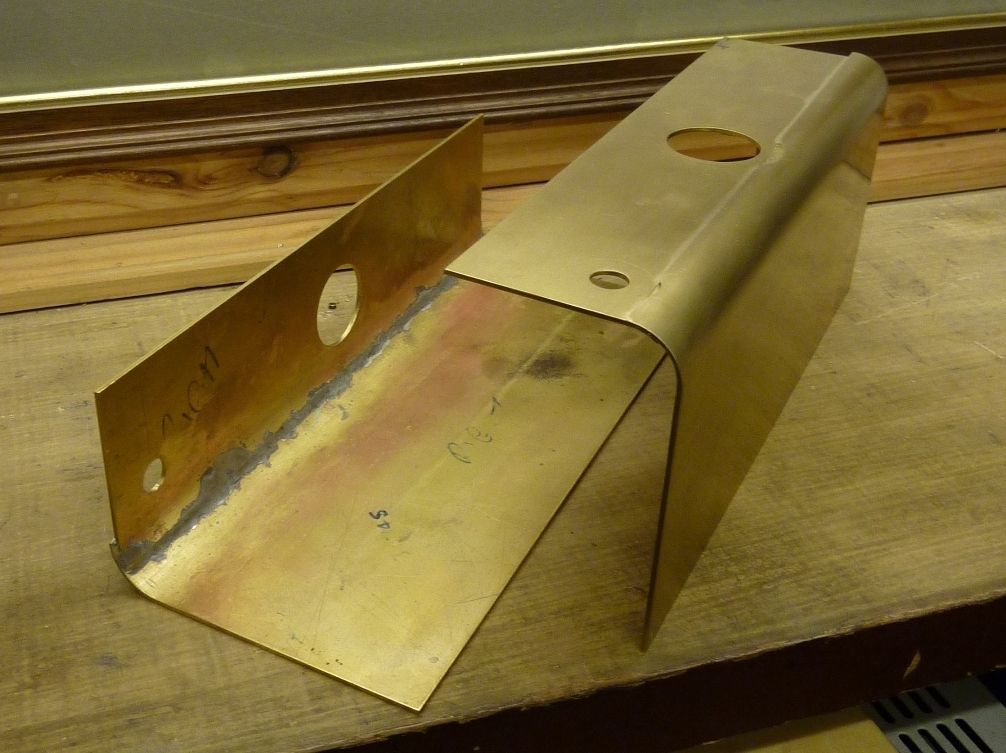

here is the first very preliminary stage of making the Stroudley side tanks   these are the outer covers to the side tanks all cut and filed to size except in length from top to bottom. the Stroudley side tanks have a false outer cover. to re-create this in miniature creates a number of problems. as a result you can bin the martin evans and don young drawings for 5"g and 7.25"g! the martin evans drawings are totally wrong anyway as the tanks are too wide and not tall enough to scale. so we start from scratch. Jim Scott was subjected to my views on Stroudley side tanks and has produced excellent tanks for his own 5"g terrier. now i am having to do my own without Jim's skill. the Stroudley tanks have a curved top outer edge. no help at all from martin evans' or don young's construction series as to how to achieve this. my first attempt this evening was a disaster as the set up was wrong and something slipped and the bend started off in the wrong place. so i annealed the brass plate to hammer out the bend in the wrong place. after annealing the brass plate it went all banana like and took ages to flatten. anyway the bend with a different set up using a section of the kitchen work top went extremely well and only took a a minute. then i attempted to bend the other outer cover of hard brass plate using the same method and not good at all. it will also require annealing before finishing the bend. on the fullsize outer covers there is an overlap and step on top of the top plate. Jim has done this to his and i will do the same as it is quite a feature of the fullsize locos and easily seen from above in miniature. this requires cutting the outer cover quite close to the bend on the top. this will hopefully be clear in later progress pics. cheers, julian |

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Dec 17, 2015 0:16:53 GMT

this isnt a very good pic as taken in darkness to judge the brass colour whilst heating, but the other outer cover whilst annealing. it also went banana like after annealing so will require similar treatment to flatten either side of the bend. i must have a very pre-stressed sheet of 1/16" hard brass that these sections were cut from! i dont recall the banana problem before!  today's lesson for such a long curve of just under 9" length is that you need to anneal the brass sheet first! do martin evans or don young mention this? no! cheers, julian |

|

|

|

Post by Roger on Dec 17, 2015 10:40:00 GMT

Very valuable lessons there, I'm making note of this Julian.

|

|

|

|

Post by ejparrott on Dec 17, 2015 11:27:54 GMT

I've got similar to do with the bunkers for my MW, front vertical corners, they need to be right! I've been putting it off and putting it off...going to have to do it soon though....

|

|

|

|

Post by Jim Scott on Dec 17, 2015 12:24:01 GMT

the Stroudley tanks have a curved top outer edge. no help at all from martin evans' or don young's construction series as to how to achieve this. my first attempt this evening was a disaster as the set up was wrong and something slipped and the bend started off in the wrong place. so i annealed the brass plate to hammer out the bend in the wrong place. after annealing the brass plate it went all banana like and took ages to flatten. anyway the bend with a different set up using a section of the kitchen work top went extremely well and only took a a minute. then i attempted to bend the other outer cover of hard brass plate using the same method and not good at all. it will also require annealing before finishing the bend. Hi Julian You're on the final straight now, the tanks are the last major components to make and as I've said before, their addition produces the final 'Terrier' appearance. I wish No 83 was as close to completion as you are with Stepney... As you have discovered, bending the tank top radii can be a bit trying. Luckily (?) I had the opportunity to make the bunker back plate first and almost scrapped it for all the reasons you state above. I could (should) have made a new one in the time it took to flatten, reshape and restore the surface finish after annealing. Not having any specialist equipment, my tank sides were formed from half hard 1/16" brass sheet over a suitable length of round bar, the whole being held in the bench vice between heavy steel angles. The trick is to make absolutely sure nothing can slip, numerous additional G-clamps and toolmakers clamps being used to ensure this. The actual forming of the bend was quite straightforward, the bend being gently persuaded using a flat ended rectangular copper dolly struck with a 1 1/2 lb hammer. Personally, I would steer clear of annealing, especially if the material has been worked - which also means that silver soldering to assemble the tanks may be inadvisable. Instead I have used my favourite silver bearing tin solder (ARAX 96S) which has reasonably good mechanical strength but with a application temp of just 221 C. Look forward to seeing the continuing construction. Jim S Arrangement for holding plates for bending (Aug 2012)  Sides and tops, lap joint soldered with ARAX 96S solder (Aug 2012)  |

|

|

|

Post by Roger on Dec 17, 2015 12:29:35 GMT

Hi Jim,

What's your method of encouraging the metal to fold over the former? I usually use a soft metal block, say of Aluminium and a mallet, working my way along but It's not ideal. Ideally I'd like to form the whole shape in one length.

|

|

|

|

Post by Jim Scott on Dec 17, 2015 12:47:16 GMT

Hi Roger

Exactly as you state. I have a copper dolly about 3/8" x 1 1/2" x 4" long which I work back and forth along the joint. With care this will give a very acceptable result. To form the whole 9" length at the same time would require a press and suitable tooling, something I don't have access to these days.

Jim S

|

|

|

|

Post by Roger on Dec 17, 2015 14:38:45 GMT

Thanks for that Jim. I've had problems with that method in the past where there's a tall piece to fold over, and that can end up bent unless the soft block rests up against the whole face I'm trying to fold over. My friend has a 'Box and Pan Folder' and it might be possible to use that if I make up some sort of radius tool for the length of the tank.

|

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Dec 18, 2015 9:16:34 GMT

as we are a bit short on construction stuff at the moment, and as ive done nothing in the workshop the last 2 weeks, and as Jim Scott has sent me some brilliant pics ive taken the liberty of adding them here! these are for Jim's own excellent 5"g terrier which is quite a bit more advanced than my own. awhile back i was pontificating to Jim how i much prefer proper leaf springs as the loco performs so much better on the track with them. i'd made my own split axleboxes to incorporate a central pin for leaf springs and made the connectors to the spring buckles. Jim had already made his as per Martin Evans, and then cut them up to make them split and replaced the coiled spring studs with a recess and pin for proper leaf springs. anyway here's the finished products, and i hope you will all agree Jim has made a very fine job of them! ive been putting off making them as it's quite a long job to get right - but well worth it in the end... so ive no excuses now not to follow Jim's excellent examples! incidentally we found the original detailed Stroudley drawings of same in 'The Engineering' magazine of 1873! cheers, julian    Just happened upon this, (a google search on leaf springs brought this thread up,) and I cannot believe my eyes, they are simply stunning. I cant stop looking at them! Such an amazing piece of work. Tim. |

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Dec 18, 2015 21:05:42 GMT

a few more pics... first is the outer covers after hacksawing and filing the edge close to the bend  i find with platework you have to arrive at some non metal work set ups that in my case are more like woodwork set ups.  the above is a trial location of one of the outer covers. have to be very careful to get the correct top level for the handrail stanchions and outer dome! note the overlap on the cab which is as per prototype.  above is what all the fuss is about with Stroudley side tanks. an old pic of fullsize Boxhill taken at Clapham Museum. you will note that the outer cover is false and a step where it joins what i call the top plate. also lots of interesting details such as the scallop for the tank filler in the outer cover, and detail of the tank filler and lid. my Grandpa took me to Clapham Museum when i was 4 years old and we ate our packed lunches alongside Boxhill. now the time consuming process of fitting to place brass angle and riveting it to the outer covers. every thing else will be built up around the outer covers - well that is the plan at the moment! cheers, julian |

|

|

|

Post by Roger on Dec 18, 2015 21:09:01 GMT

Good progress Julian, but I'm confused as to why these were fitted to the original?

|

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Dec 18, 2015 21:43:06 GMT

hi roger,

i dont know the exact answer for the false outer covers for the side tanks. it was a feature of all Stroudley tank locos. i always believed it was to act as some form of insulation for the tanks as part of the exhaust steam was used to condense into the tanks to heat up the water. hence why Stroudley used feed pumps rather than injectors, as injectors would not work at the feed water temperature in the tanks.

when you see the inner tanks in fullsize they are covered with rivets and joints. this would have offended Stroudley's view of having a perfect finish for painting. so perhaps another reason for the outer covers.

cheers,

julian

|

|

|

|

Post by Jim on Dec 18, 2015 21:45:13 GMT

Good progress Julian, but I'm confused as to why these were fitted to the original? I'm not sure but possibly because it was just pleasing to the eye and concealed the very utilitarian lines of the side tanks. One of the things I love about the Victorian/Edwardian era is the attention to detail in designing locomotives that not only ran well but were works of art in their own right. Stroudly and Johnson are are among my favourites. Back on task, Julian you are certainly doing a brilliant job recreating one of the great locomotives of that period. Jim |

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Dec 18, 2015 22:33:32 GMT

thanks Jim!

i think the second lesson from yesterday is that as per Jim Scott and Carl Jones' advice it would be best NOT to anneal brass plate, and achieve the bends with a method that doesnt require annealing! if i wasnt so impatient with platework i ought to have made up a proper set up, though i do think my brass sheet was extremely hard. i dont recall other brass sheet being so awkward to bend. perhaps i cut the sheet the wrong way for the grain for the bend. it is an old sheet 1m x 1m i bought 16 years ago and hasnt been used for anything else till now.

cheers,

julian

|

|