|

|

Post by simplyloco on Jun 22, 2019 22:45:39 GMT

I agree these 3D printers are a fantastic tool SNIP But, hey, you're already a very good machinist and time to showcase a new skill, maybe? Regards, Steve Hi Steve A great compliment, for which I thank you, but as I can already do it quite well the 'traditional' way, I'm very happy to embrace new technology - just like Roger - and make life a little easier for myself...  Regards John |

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,990

|

Post by JonL on Jun 23, 2019 11:26:58 GMT

I think the thing I enjoy about this hobby is how many different ways there are to crack the same nut. It's all bespoke skills, we all broaden our experiences and fall on techniques that we prefer. All of the locomotives in build at the moment are using very different techniques and I love watching them all evolve.

|

|

|

|

Post by simplyloco on Jun 23, 2019 16:08:37 GMT

First job today - after I'd fixed a new wheel onto Madam's hobby trolley - was to cut out the coal chute apertures. Another job for the Proxxon: 3mm carbide roughing out at 5000 rpm! There is a shim under the plate, so there are no new slots in the bed...  20190623_160523 20190623_160523 by inkaboat, on Flickr A top filing tip when doing apertures: use a piece of HSS clamped in the vise along a scribed line. When the file skids you have a perfect straight line!  20190623_154558 20190623_154558 by inkaboat, on Flickr That'll do nicely.  20190623_155855 20190623_155855 by inkaboat, on Flickr The angle brackets are quite large, and are held on with genuine Araldite - not the Chinese variety! The square support bars and the double clamps ensure that the tender sides remain flat.  20190623_163909 20190623_163909 by inkaboat, on Flickr Coal bucket tomorrow! John |

|

|

|

Post by franstrein on Jun 24, 2019 11:43:39 GMT

Hi John,

Good to see that you are back at building the tender !

Your info and pictures on using the 3D printer is very interesting..

I have been thinking on 3D printing as well in the past.

However I didn't see this possible on a live steam locomotive, with hot parts and fluids and steam around...

I expect the parts would easily get damaged..

Curious on your considerations on this?

(Or I might need to wait for affordable 3D printers using metals...).

Thanks,

Frans

|

|

|

|

Post by simplyloco on Jun 24, 2019 14:12:46 GMT

Hi John, SNIP However I didn't see this possible on a live steam locomotive, with hot parts and fluids and steam around... I expect the parts would easily get damaged.. Curious on your considerations on this? SNIP Thanks, Frans Hi Frans Not a lot of hot stuff around the tender to affect the plastic parts, but who said anything about putting live steam through my beautiful Britannia?  John |

|

|

|

Post by simplyloco on Jun 24, 2019 17:14:43 GMT

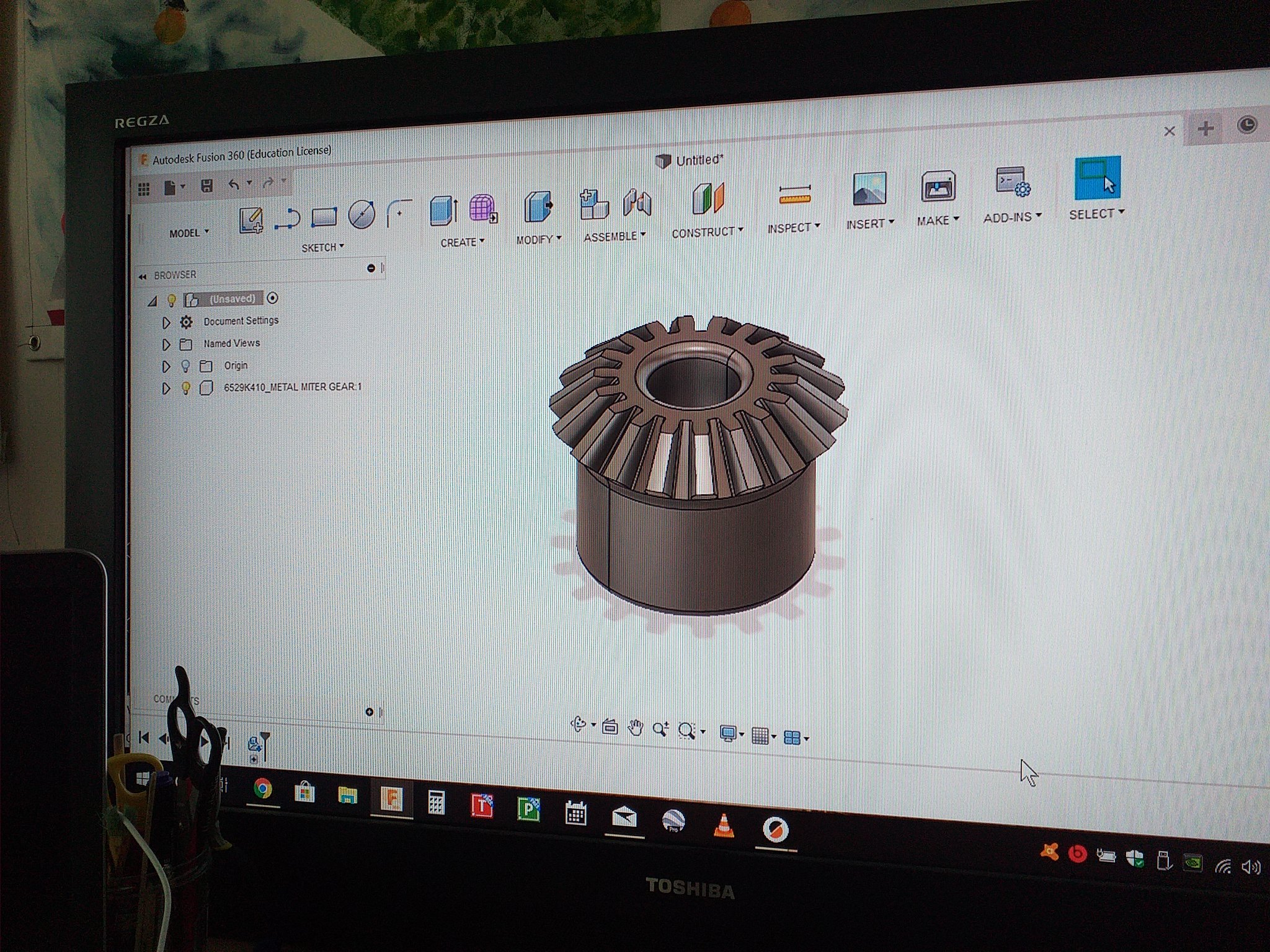

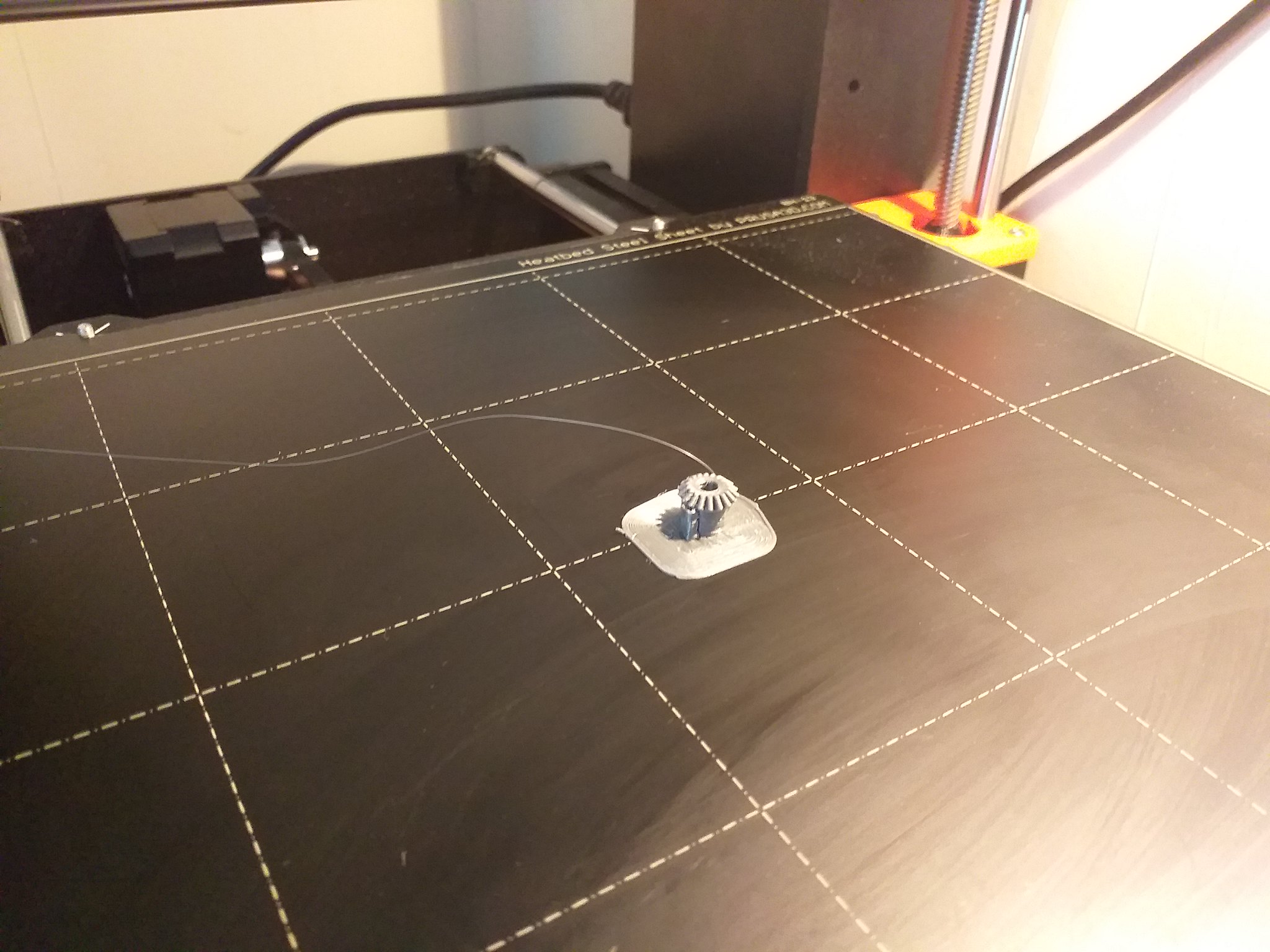

Moving on with my Airfix kit, I've been exploring bevel gears for the tender brakes: after all, they are for decoration only... Imagine my surprise to find that with Fusion 360 I can dive in to McMaster-Carr's catalogue, and download 3D drawings of thousands of their parts, for free! Here's the proof. 0.375"body dia.  20190624_175531[1] 20190624_175531[1] by inkaboat, on Flickr Sliced by Prusa  20190624_175203[1] 20190624_175203[1] by inkaboat, on Flickr I'm not suggesting that this is useable with the 0.4mm nozzle, but it was printed in six minutes...unbelievable! I have a 0.2mm one   20190624_181746[1] 20190624_181746[1] by inkaboat, on Flickr |

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,990

|

Post by JonL on Jun 24, 2019 17:19:25 GMT

Thats astonishing. Just think, if this generation can do this, what will the machines of 3 years time achieve?

|

|

|

|

Post by simplyloco on Jun 25, 2019 17:46:39 GMT

Coal Bunker

Back to Tin Bashing!

My first go at this, and I've decided to keep it simple: for my benefit mainly... My intention was to make up the bunker in one piece, parallel to the floor, and just drop it in to make the top side walls at the same time. I got it wrong so I will have to make another! It will be correct next time, but I've got a root canal appointment tomorrow so there may be some delay...   20190625_174245 - Copy 20190625_174245 - Copy by inkaboat, on Flickr  20190625_174251 20190625_174251 by inkaboat, on Flickr  20190625_175148 - Copy 20190625_175148 - Copy by inkaboat, on Flickr

|

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,990

|

Post by JonL on Jun 25, 2019 17:56:55 GMT

It's certainly got to this stage swiftly; I don't imagine it will take you long to rectify a small issue. Best of luck with that and your root canal!

|

|

|

|

Post by simplyloco on Jun 25, 2019 18:03:31 GMT

It's certainly got to this stage swiftly; I don't imagine it will take you long to rectify a small issue. Best of luck with that and your root canal! As if I need something else to get my teeth into!  |

|

|

|

Post by simplyloco on Jun 26, 2019 17:36:26 GMT

I managed a couple of hours in the workshop today. It was quite therapeutic as I had paid a £498 service bill on my car this morning! The dentist let me off the root canal for some reason... I've salvaged the coal bucket as I've copied Jim's idea for the display tray that will contain the 3D printed coal. I'll bond the outer plate to the top edge of the hopper, and then attach a small ledge to carry the tray. You won't see the join! Great progress!   20190626_175632 20190626_175632 by inkaboat, on Flickr  20190626_182810[1] 20190626_182810[1] by inkaboat, on Flickr |

|

|

|

Post by springcrocus on Jun 26, 2019 18:19:54 GMT

............ 3D printed coal. Love it!  Regards, Steve |

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,990

|

Post by JonL on Jun 26, 2019 21:46:39 GMT

3D printed coal, thats going to smell funny when it burns...

|

|

|

|

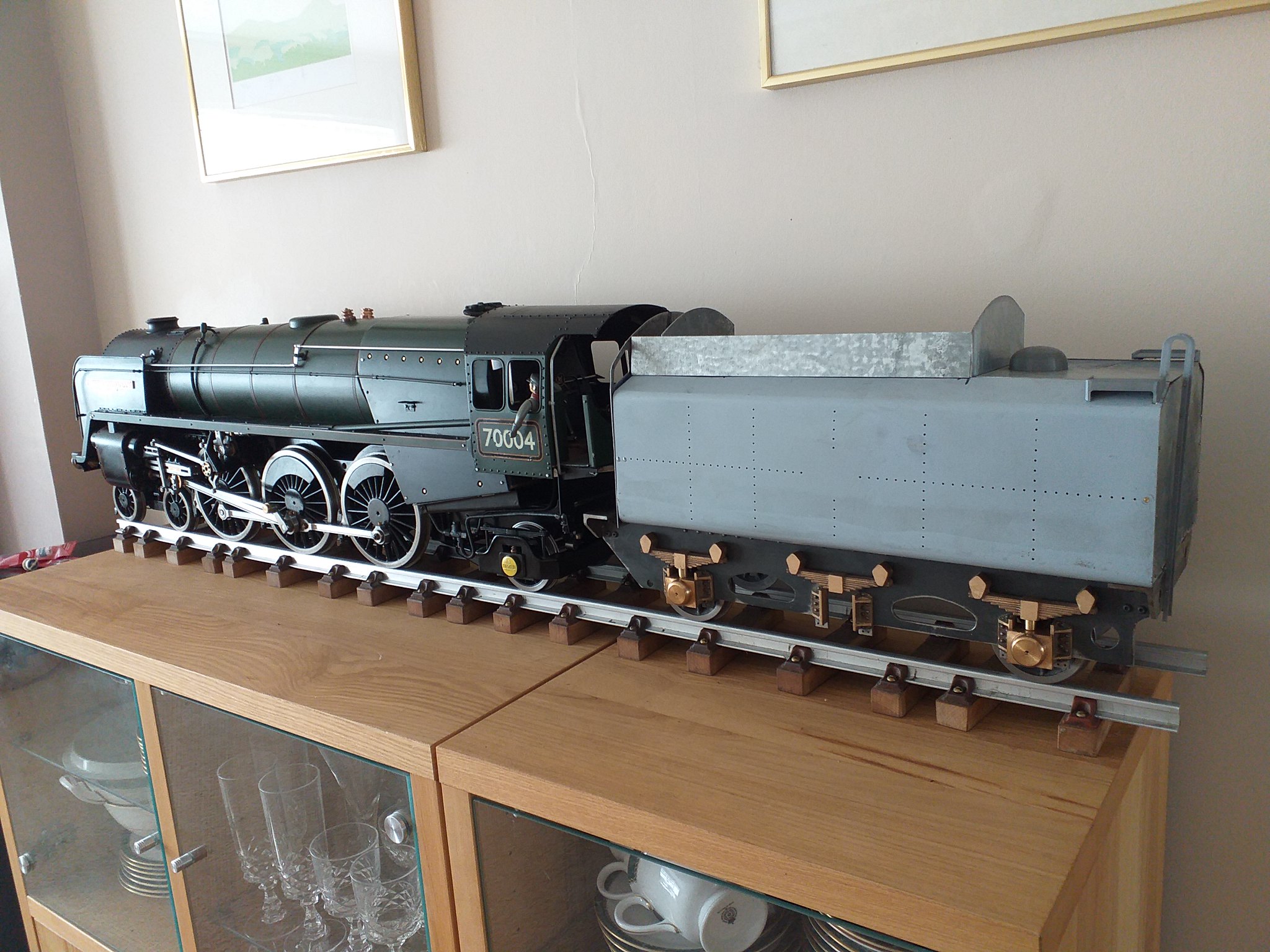

Post by simplyloco on Jun 28, 2019 14:33:53 GMT

Having got this far quickly and without mishap, I couldn't resist a 'sideboard' tryout before I slap the engine end panel on and fit the bunker tops. I was very pleased with it until I tried to close couple it. The ride height is fine, the drawbars match up exactly, and the proportions seem Ok.  20190628_145638 - Copy 20190628_145638 - Copy by inkaboat, on Flickr Still looks OK!  20190628_150420 - Copy 20190628_150420 - Copy by inkaboat, on Flickr I discovered why I couldn't get the thing coupled. The chute is much too low! After checking drawings I remembered that I had to make some alterations to the cab to accommodate boiler cladding thicknesses, etc. This altered the cab height. A replacement end panel is needed I'm afraid.  Still, it looks nice, especially the firebox top rise and the lagged pipework, and the hand rails are straight too.....  John  20190628_145622 - Copy 20190628_145622 - Copy by inkaboat, on Flickr |

|

|

|

Post by simplyloco on Jun 28, 2019 19:49:56 GMT

Forgive the mess but I've been removing bits trying to get to the problem. The specified height of the cab floor and tender coal chute is 4.75"above the rails. My coal chute is correct to drawing but 0.25" too low given the increased cab height. I have raised the chute by the increase in cab height. Trouble is, there is a back draught plate 0.5" high which blocks the entry of the coal chute even if both heights were correct! I can see me hacking a big hole in plate ... Has anyone got a photo of the chute and the cab floor? Thanks John  20190628_202025[1] 20190628_202025[1] by inkaboat, on Flickr |

|

|

|

Post by Deleted on Jun 28, 2019 20:28:42 GMT

That figure doesn't look like you John...  talk to Andrew at hardyshobbies.co.uk/ and he will scan you and 3D print your figure. He will dress you in suitable attire for whichever crew member you want to be, driver, firemen... even station staff, sitting, standing, holding a shovel, etc etc... Give him measurements of your cab and he will make the figure a perfect fit. Not cheap but not dear either, it's something that I plan to do at some point in the future..  Pete |

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Jun 28, 2019 22:41:18 GMT

Check out Jim's Boudicea build thread, page 60. 😉

Mike

|

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,990

|

Post by JonL on Jun 28, 2019 22:49:26 GMT

I just had a look at my Oliver Cromwell reference pictures but I can't find anything of the coal shute, just a view into the bunker that doesn't show much. No matter how many pictures you take there will always be something you miss...

That aside, I think the tender is looking fantastic.

|

|

|

|

Post by simplyloco on Jun 28, 2019 23:03:17 GMT

Check out Jim's Boudicea build thread, page 60. 😉 Mike Thanks Mike That backdraught plate looks a lot lower than the LBSC one! I'll act acordingly. John |

|

|

|

Post by Jim on Jun 29, 2019 6:23:20 GMT

Hi John, These photos may be of help along with a side view of works drawings of the cab. Sadly the very big sheet I have of the Derby Works Drawings is only the side view of the Britannia and doesn't include end views. They must have been on another sheet which I never had.

The photos are from various sources including Richard Derry's Book of the Britannia Pacifics. Jim |

|