|

|

Post by Deleted on Mar 31, 2017 18:09:21 GMT

I've used the iPhone for setting angles on film sets, it is surprisingly accurate....it's good at recording your 0-60 times too....  Pete |

|

|

|

Post by 92220 on Mar 31, 2017 18:29:49 GMT

4 secs??

|

|

|

|

Post by Deleted on Mar 31, 2017 21:19:05 GMT

It was certainly low 5's before the last big upgrade...no idea what it is now as I no longer use an iPhone...in standard form with 220bhp it was 5.9 secs (auto test figures)... I am now over 400bhp...I wonder what it does now?...  |

|

|

|

Post by 92220 on Apr 1, 2017 12:02:16 GMT

Wow! Another like-minded geriatric boy racer? Am I not alone then?!!?!!! I'm still standard at 280php and 5.7 secs.

|

|

|

|

Post by Deleted on Apr 1, 2017 12:20:00 GMT

Wow! Another like-minded geriatric boy racer? Am I not alone then?!!?!!! I'm still standard at 280php and 5.7 secs. Haha...'geriatric' is the word, well it is according to SWMBO who seems to get great pleasure in telling me that I 'drive like an old man' these days....mind you she's more used to me driving at very high speeds, we have been together for all of my driving life and I was very much a 'petrol head' in my youth. I no longer drive at speeds up to 2 1/2 times our national speed limit, though, only on the continent of course....  5.7 with 280bhp sounds like 993 territory if talking Porsche? Pete |

|

|

|

Post by 92220 on Apr 1, 2017 16:13:56 GMT

No Pete. A Porsche is just a bit out of my league!! Limited to an Astra J VXR, but that's fast enough for me. Like you, in my younger days I was a 'petrol head'. I used to rally with the Cheltenham Motor Club. Best car I ever had was a Vauxhall Chevette HS. 175bhp at the wheels, weighed in at less than a ton and 0-60 in around 5.2 secs....in 1980! Sounds unbelievable acceleration for that year but the gearing was such that top speed was only 115mph, and I could red-line it in top gear! They were the days.....no speed cameras and only motorway cops sitting in their cars on the slip roads.

Ouch. Sorry David. I didn't mean to hijack your thread!

Bob

|

|

|

|

Post by Deleted on Apr 1, 2017 16:31:31 GMT

Yes..sorry David for getting carried away talking cars, last one from me now... It's good to know I'm not the only petrol head on here Bob....yes the days of free driving are long gone. That sounds one hell of a Chevette you had there Bob...btw I can red line in top....she has very long legs too:) Something the standard car couldn't do, Porsche designed the wastegate to open as soon as boost appeared in an attempt to keep it slower than the 911's, they failed and had to admit that point to point it was the fasted car in the fleet(discounting the 959 supercar). Enough car talk from me now, back to you Dave and your great loco...  Pete |

|

|

|

Post by vulcanbomber on Apr 2, 2017 8:22:00 GMT

No problem chaps.... I'm more of a derv nerd than petrol head (in rattling old land rover) so no idea about 0-60 times.... Unless that's the thing i count on a calendar?

|

|

mbrown

Elder Statesman

Posts: 1,796

|

Post by mbrown on Apr 2, 2017 11:09:11 GMT

Someone once said of the locos on the Talyllyn Railway that they go 0 to 1/4 mile in 60 seconds......

Malcolm

|

|

|

|

Post by 92220 on Apr 2, 2017 17:15:36 GMT

Roger Bannister must have been pushing!!

|

|

|

|

Post by vulcanbomber on Apr 10, 2017 19:43:31 GMT

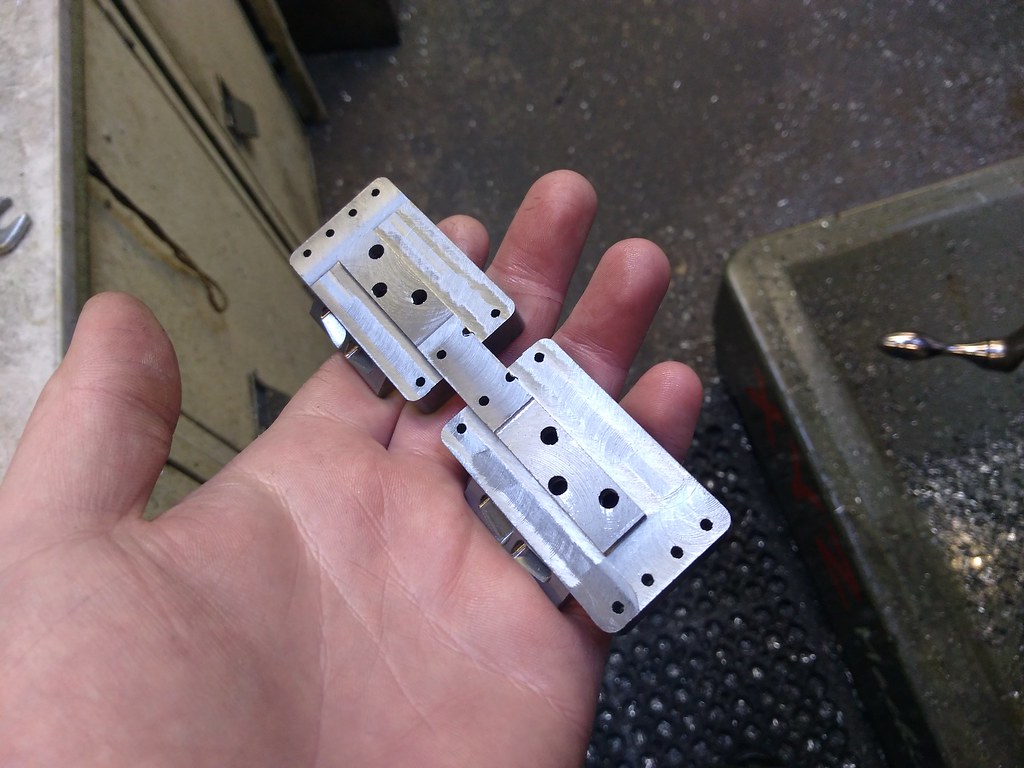

Evening once again. Progress has continued with remaking the Rear Brake Shaft Brackets. I started off the next piece by turning up some discs with a hole in it... And then bolted it to one of the cheese plates we have at work, then I drilled the holes (the bolt was also slightly adjusted) and milled the profile.   Then, bolt removed, pieces cut in 2 and then using 2 drills, the pieces all put together and put into the vice to mill the edge to size.  And the finished articles  they fit like so  And the 2 small holes will be used for dowls to locate the U channel that I goes between the 2 bits. Hopefully i'll get that made before long. thanks for looking. |

|

|

|

Post by vulcanbomber on Sept 22, 2017 22:58:50 GMT

Well, i'm guessing that you think ive forgotten you. Well, the good news is, I havnt! I have however, spent most of the summer messing with my land rover, however, with the weather coming and the dark nights coming it seemed like a good excuse to get the 9F progressing. Before I disapeared i'd spent quite a bit of time rambling on about gussets and such like. I can stop doing that now because i've been able to put the front buffer beam together with nuts and bolts, it looks something like this:   You might be able to notice the angles are overhanging ever so slightly.... I should learn to read my drawings before deciding something is finished.... Also, ive had another stretcher laser cut, this one carries the front end of the firebox.    And ive made the bolt pad for these as well, the pad will carry the back end of the rear most horizontal stretcher.  the same pads are required for the vertical stretchers that I had cut out about 18 months ago. I have one more piece to make for the stretcher that will carry the fire box and then it will be ready for sticking together. So hopefully, i will have a few months of regular updates for you. |

|

|

|

Post by 92220 on Sept 23, 2017 7:47:22 GMT

Glad to see you back and doing some work at last!!!!! Looking good David! Nice bit of machining on the buffer beam assembly.

Bob.

|

|

|

|

Post by vulcanbomber on Oct 25, 2017 21:16:43 GMT

Evening again Gents, some more odds and ends to report. First job was to alter one of the bolt pads to suit the Firebox Support Stretcher, this doesn't need machining to thickness after soldering so i reduced its thickness one one side and it needed 2 slots adding to clear round the 2 center uprights.  Then I set about making the U Channel required for the Rear Brake Shaft Support, I didnt take many photos of this, but i Set about doing this arse about face, its a lot easier to form the radius on the pro when you cant find a 2.5mm Corner rounding cutter.... Trouble is, the pro wasn't available when i started. I had to form the radius last of all when finishing the thickness, hopefully you can see the radius appearing in this 2 picture.  And this is the finished channel with its 2 ends   And finally, As a fill in job some time back i turned the Steam Brake Cylinders, I have now also made its Trunions to mount it.. these just started as a bit of bronze that was turned and Drilled. I then machined a scallop in either end to fit the Steam Brake Cylinder.  Then I put them back in the Lathe. and parted them into 2 bits.  I used the center drill to add a small lead to the Trunion to assist lining everything up in a fixture when there soldered together.  I now have just 1 bit to make and then I need to organise a big Soldering party, that will see the Rear Drag Box, a Firebox Support Stretcher, and 2 Vertical Stretchers ready for final Machining, and ill also just have the ends to clean up on the Brake Shaft Carrier. Thanks for looking. |

|

|

|

Post by vulcanbomber on Nov 10, 2017 22:47:58 GMT

|

|

|

|

Post by vulcanbomber on Nov 28, 2017 21:03:42 GMT

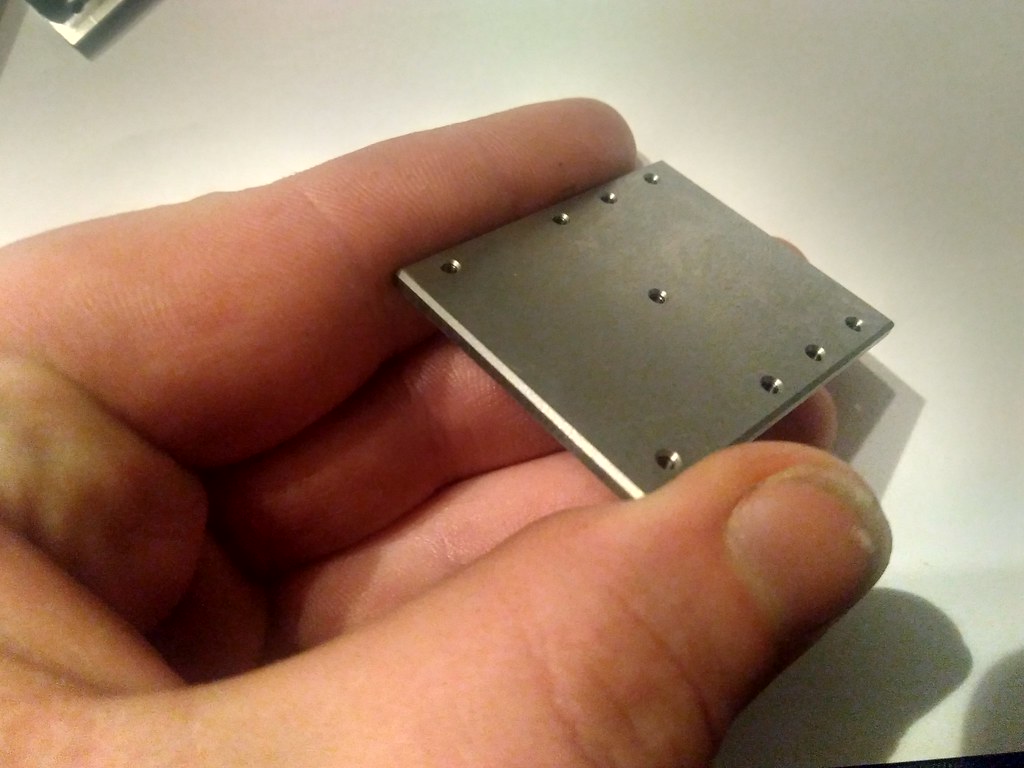

Some more bits to show on my 9F.. I've made from gauge plate the intermediate rubbing plates:  And also some more angles, these fit outside the frames onto the rear drag beam, They also run through the corner cutouts in the gussets i showed in the last update.  Hopefully, something a bit more exciting next time. |

|

|

|

Post by vulcanbomber on Dec 7, 2017 20:55:21 GMT

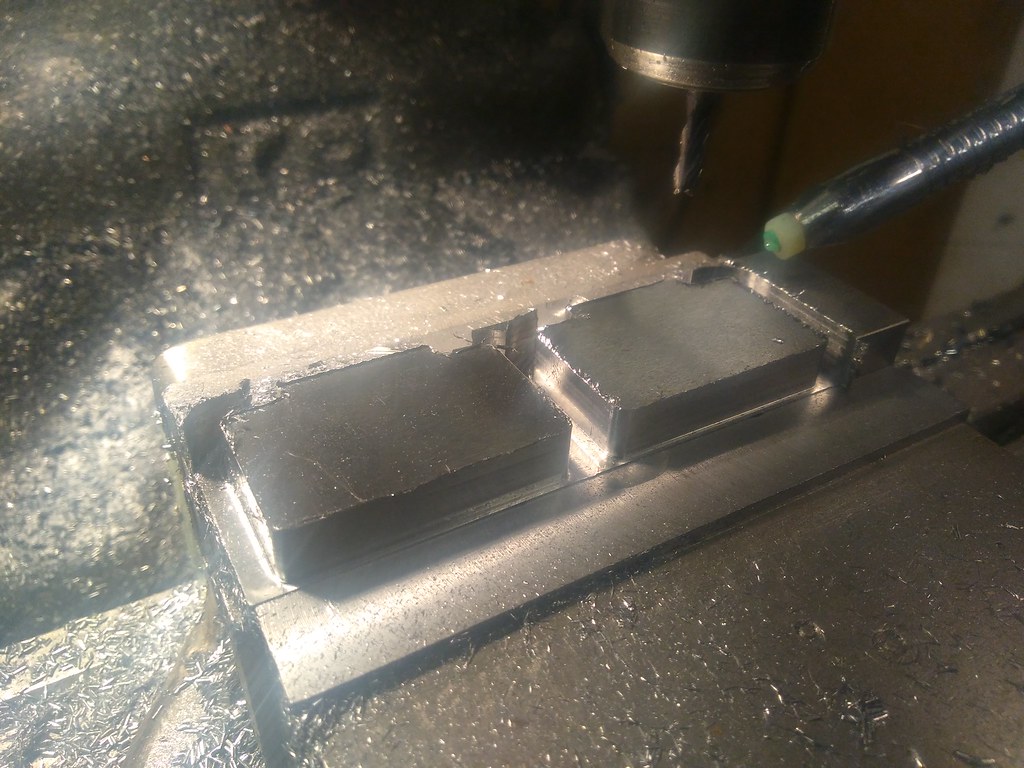

Evening readers. Just a quick update tonight to show the Rear Drag Beam now i've drilled all the rivet holes, think its 48 in total.  you can just see in the back of the picture the fixture I clamped the Beam to... its the same fixture I milled the Horizontal stretchers on over a year ago. More soon I hope. |

|

|

|

Post by vulcanbomber on Dec 29, 2017 23:24:36 GMT

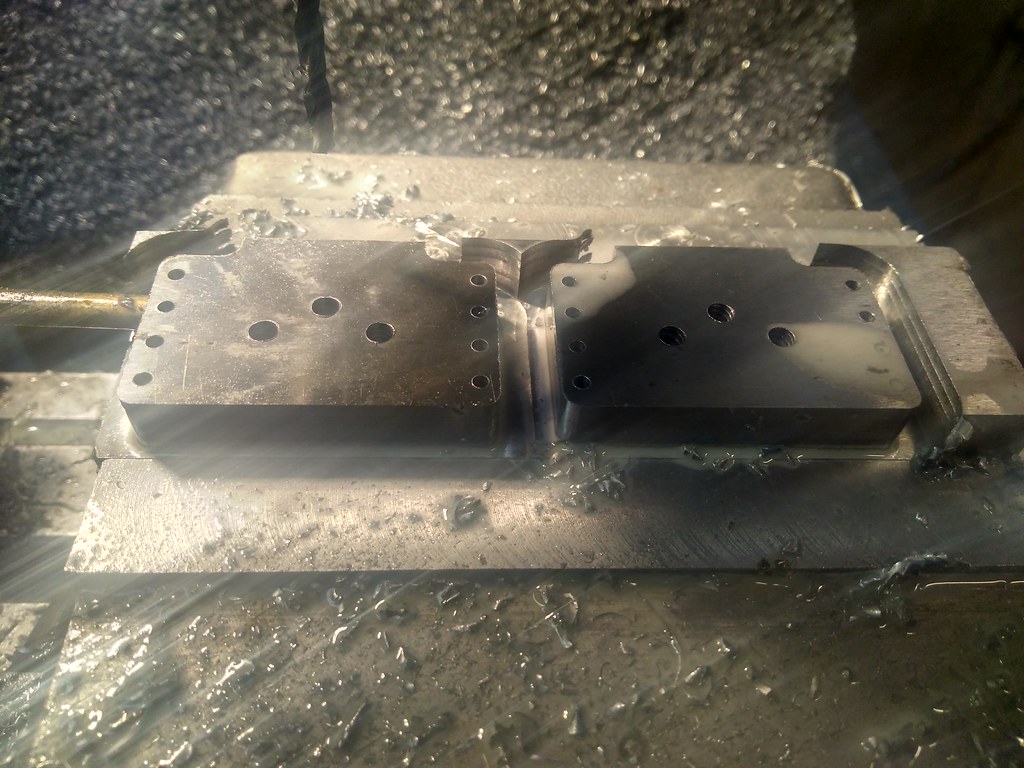

Last report for you this year, I had hoped to do this a week ago but it obviously wasn't to be. I concluded that I should probably make the last bit in need to fit the Rear Drag Beam on the Loco, so i have started on the Intermediate Rubbing Block. These were originally a Mild Steel Casting with 2 Liners welded to it for increased wear resistance, I have decided to machine mine from gauge plate. I'm actually making 4 of these, the BR1 Tender uses the same Rubbing block and also, if the 9F ever gets finished, I would like to make a BR standard 4 2-6-0 with a BR1 tender, again the same blocks will be required, so I will make them now and hopefully not lose them for when there needed in the future. Anyway, first job was to mill the outside profile into the Selected bit(s) of Gauge plate.  Next holes were drilled, the 3 grouped in the middle are tooling holes.  Next, I stood the blocks up in the vice to finish the little up stand at the top of the block, this needed a 1mm corner rad in it, not the 3mm left from milling the profile.   Next job on them is to machine an angle onto the up stand Also to show, but I take no credit for is another vertical stretcher, its all Ed's work. This one hovers over one of the Horizontal Stretchers.   I've taken these from Ed to make him a block to support the Stretcher in the vice when he machines all the meat out the 2nd side. I will also remove the stock material and drill the rivet holes in the sides and bottom face. And with that I hope you had a good christmas, and i'll wish all that read this a happy new year. |

|

|

|

Post by vulcanbomber on Jan 19, 2018 22:37:22 GMT

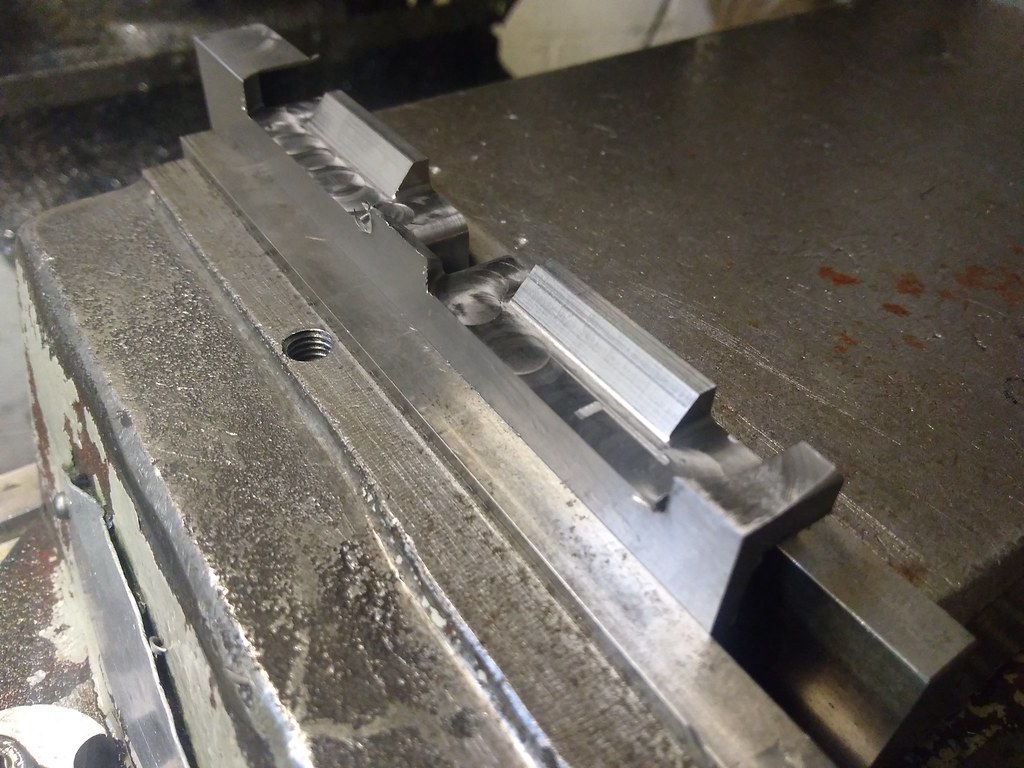

Finally time for another update on the 9F, unfortunatly, working 60 hrs a week is hampering my updates for you guys and progress on the engine! Progress has been made on the Intermediate Rubbing Blocks, first job was to machine the angle on the back edge. I did this by tipping the head over on our manual bridgeport at work.   Next I jumped on the pro to mill the 2 pockets with a 2.5mm PCB Ball nose cutter each pocket took a couple of hrs.  Next, I took the bulk of the material away from the back of the Blocks, this left me able to just bend the metal by hand and brake the 2 apart.  I then finished the back face of the Blocks.  And the final picture tonight shows the blck located on the Rear Drag Beam.  Next week I will have to make a fixture to hold these for the clever bit of these to start. Thanks for looking in. |

|

|

|

Post by fostergp6nhp on Jan 24, 2018 8:55:44 GMT

Are the holes in the right place David?

|

|