|

|

Post by ejparrott on Oct 28, 2014 18:02:04 GMT

Good to see you, and the castings looked amazing!

|

|

44767

Statesman

Posts: 538

|

Post by 44767 on Dec 27, 2014 1:07:28 GMT

Well, just to let you know that I am still on the project here is an update. Since returning from China and the UK I have been busy getting the wax printer up and running. It seems there are some on board software issues which still need to be resolved but that is not important to discuss here. As you have seen elsewhere on these pages, Adam has had me produce castings for his exquisite brake valve. This is just the sort of casting the printer is best for so I hope you will all find similar items to produce now that you won't have to pay anything like commercial type rates for such things. Here is a photo of the main parts of the pony truck "assembled" to get a feel for it.  Also just before Christmas I picked up some springs I had made. I need to do some testing on these as even though they look correct I am sure they are too strong. To get around this I will probably get them wound using a smaller diameter wire and dip them in paint several times to thicken them up. I feel that in our scales the pony truck suspension springing should be enough only to hold the wheels on the track i.e. they should have very little weight on them but still keep all wheels on the track no matter what. So almost the whole weight of the loco should be balanced on the driving wheels only. I am doing work on the side control springs too. This is a deep rectangular section which won't be easy to replicate but I have found that even with round wire with the correct number of turns it is a good representation and about the correct spring rate. Again on the model this needs not be very stiff to do its job in this scale. I'm looking forward to getting home in a few days to get into the workshop and machine up these bits. Mike |

|

|

|

Post by Jim on Dec 27, 2014 1:44:06 GMT

Good to see you back on the site Mike along with those superb castings of yours.

Al the best for the New Year,

Jim

|

|

|

|

Post by Rob on Dec 27, 2014 12:18:16 GMT

Well, just to let you know that I am still on the project here is an update. Since returning from China and the UK I have been busy getting the wax printer up and running. It seems there are some on board software issues which still need to be resolved but that is not important to discuss here. As you have seen elsewhere on these pages, Adam has had me produce castings for his exquisite brake valve. This is just the sort of casting the printer is best for so I hope you will all find similar items to produce now that you won't have to pay anything like commercial type rates for such things. Looking good as usual! What printer do you use? |

|

44767

Statesman

Posts: 538

|

Post by 44767 on Dec 27, 2014 12:47:18 GMT

I have the 3d systems 3510 cpx which prints only to wax. It has a 16 micron layer thickness in the extreme high definition mode.

|

|

|

|

Post by ejparrott on Dec 30, 2014 21:44:42 GMT

I agree on the springing of pony trucks and bogies, enough weight to guide it and stabilise it, and if on ground level to throw over trailing points - this is a problem I have with the club's Scot, it hasn't enough weight to throw over the points.

|

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,856

|

Post by uuu on Dec 30, 2014 22:21:24 GMT

If you want a pony truck or bogie to do the job it was designed for, then you need to give it the load it was designed for. They weren't put on as decoration.

Wilf

|

|

|

|

Post by Deleted on Dec 30, 2014 22:43:14 GMT

As a pointer for loading on your model why not have a look at the full-size weight diagramme, then use % weights of the loco's total on each axle to give you an indication of what to expect ??...........

|

|

|

|

Post by ejparrott on Jan 7, 2015 9:08:28 GMT

As a pointer for loading on your model why not have a look at the full-size weight diagramme, then use % weights of the loco's total on each axle to give you an indication of what to expect ??........... Trouble is, what is the weight of the loco to start with? That's why I said weight (!) until the loco is finished then you can get a real figure to begin with |

|

44767

Statesman

Posts: 538

|

Post by 44767 on Jan 18, 2015 8:15:23 GMT

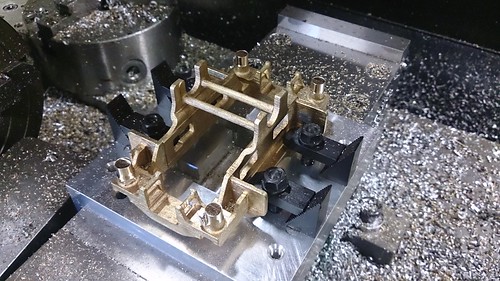

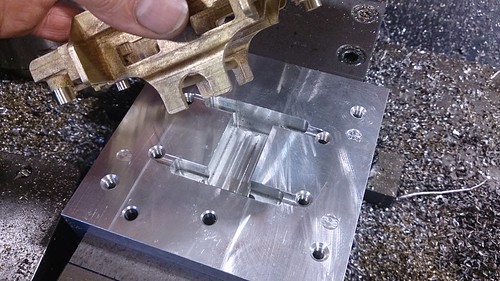

The springing will have to wait until the loco is on its wheels. It's a small matter to fit different springs if these aren't suitable. Until then these look right anyway. So a bit of progress this weekend. I have been machining the pony truck main casting. At the moment I am only doing two. I want to get a couple done so that it can be used as a sample of what I'm doing. Later, of course, there are at least nine more to do so I have spent a bit of time making a milling fixture to make the job quicker and easier. This fixture is for the first two operations.  First the dowels are inserted:  Then the part is located:  And clamped:  The clamps you see are ones I made years ago. They use 1/4" studs and really are just a half size version of ones we use on larger mills. Anyway they are proving very worthwhile for doing this sort of work. Dowels removed and machining of the pillars done (skimmed to height and milled to size to suit the second op part of the fixture):  The pillars were put on the casting so that the foundry could attach their runners to it (and not somewhere I didn't want it). I put four in so that they could be used for setting up the job too, as seen here. Now the part is located in the counterbores and clamped for the second op:   And here's the second op complete:  I am now making another fixture which will locate on this machining for the other side and it will be used in the dividing head to machine all the other four faces. More later when that's done, |

|

44767

Statesman

Posts: 538

|

Post by 44767 on Jan 18, 2015 8:27:17 GMT

Also done this weekend were the pony truck axleboxes. The keeps were machined first. Then the axleboxes machined to accept them. The two were clamped together and drilled for the dowels which locate the keep. I have used drill blanks for the dowels. They come in a wider variety of sizes and are as long as a jobber drill of the same diameter. I just cut them to suit. Once the castings are together they were faced and bored in the mill.  As per the full size ones, the keep is left and right hand- handed by the filler/drain. This has a gallery through into the sump so it can be used to refill the keep with oil. |

|

|

|

Post by ejparrott on Jan 18, 2015 10:10:24 GMT

That's Brilliant Mike...yes...Brilliant with a capitol 'B'!!

Are they the same pont truck axleboves as the Standard 4 tank? Might just be tempted for a pair for mine.... David might want some for his 9F too...the detail on that is awesome!

|

|

|

|

Post by Deleted on Jan 18, 2015 10:16:32 GMT

I'll second Edd's comments...lovely work Mike..I saw the axleboxes on FB...very impressive sir....I love detail and they have it in abundance...great work..

Pete

|

|

44767

Statesman

Posts: 538

|

Post by 44767 on Jan 18, 2015 10:21:34 GMT

That's Brilliant Mike...yes...Brilliant with a capitol 'B'!! Are they the same pont truck axleboves as the Standard 4 tank? Might just be tempted for a pair for mine.... David might want some for his 9F too...the detail on that is awesome! Yes, Ed, these are the standard axleboxes. They were the same on all the standards. I think the ones for the bogies (for the 2-6-4 tank, class 4 4-6-0 tender, class 5, and the Pacifics were similar but the guides were different. Just a variation which I could do. Your words are too kind but I must admit I am rather pleased with them! |

|

|

|

Post by Deleted on Jan 18, 2015 13:59:01 GMT

I will further reinforce the previous comments Mike, your work is awe inspiring, I wish I had the means to attempt to follow your high standard!

Regarding the axleboxes yes they were the same across the board for all Standards bar various which had roller bearings fitted to them, it this case they had cannon boxes. 73082 (Camelot) has roller bearings all round, engine and tender, I believe all class 5s were the same but don't know that for sure. I also believe some Brits were roller bearing fitted too

Cheers

Ben

|

|

|

|

Post by ejparrott on Jan 18, 2015 14:09:47 GMT

What would be the damage on a pair of axleboxes Mike? To the UK obviosuly!

|

|

|

|

Post by vulcanbomber on Jan 18, 2015 17:41:24 GMT

What would be the damage on a pair of axleboxes Mike? To the UK obviosuly! Or even a job lot? |

|

|

|

Post by trainman on Jan 18, 2015 20:33:36 GMT

Hi Mike,

Great job as usual - can I join the queue for a pair for my Britannia please?

Regards

Paul

|

|

44767

Statesman

Posts: 538

|

Post by 44767 on Jan 19, 2015 7:59:07 GMT

Hi Mike, Great job as usual - can I join the queue for a pair for my Britannia please? Regards Paul You'd need four wouldn't you Paul? |

|

|

|

Post by trainman on Jan 19, 2015 18:39:16 GMT

Quite right!!

Thanks

Paul

|

|