|

|

Post by Rob on Dec 28, 2014 21:48:40 GMT

For folk like me in the mill, file and fabricate world, work like that is simply mind blowing. Beautiful workmanship Tim.  Jim Seconded!  |

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Dec 29, 2014 9:44:04 GMT

For folk like me in the mill, file and fabricate world, work like that is simply mind blowing. Beautiful workmanship Tim.  Jim Seconded!  Thanks Jim and Rob but seriously guys I see it as anyone making something like this any way other than I have on a machine, as equally mind blowing. Regards Tim. |

|

|

|

Post by Shawki Shlemon on Dec 30, 2014 8:32:08 GMT

I do agree with others here , its fantastic .

|

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Dec 30, 2014 17:29:54 GMT

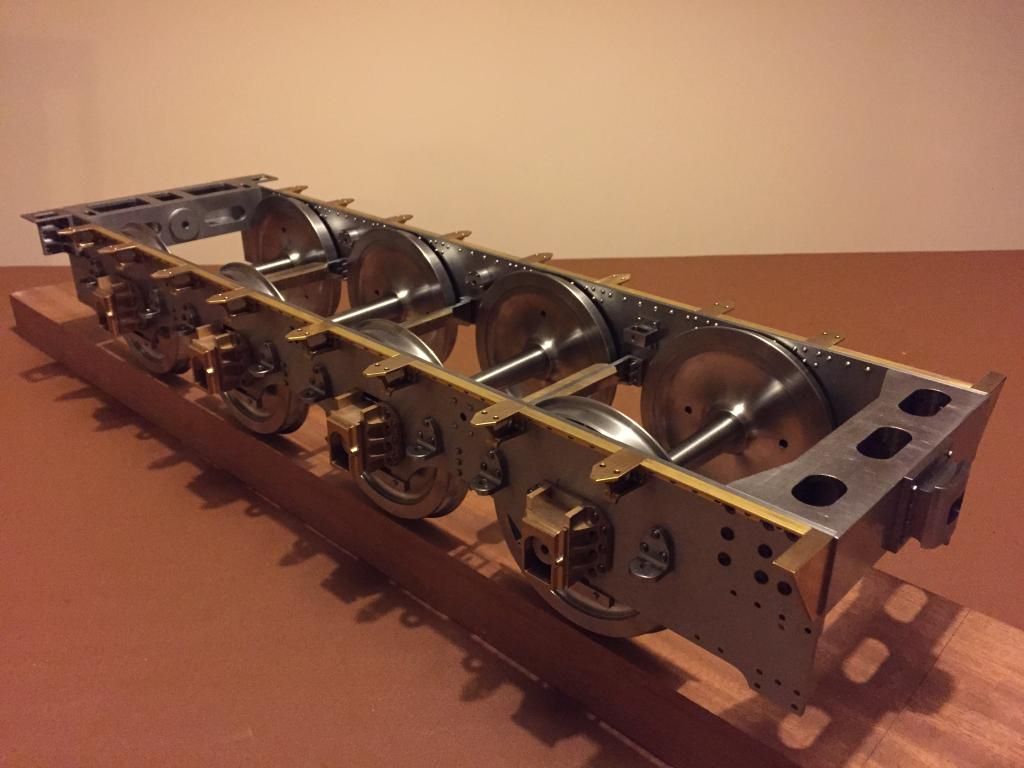

Evening chaps, having machined the additional material from the back face of those intermediate axle boxes so that they now fit onto the axles, I was finally able to assemble everything I have so far to give me a rolling chassis, ( a long time coming!!!) Next thing I will be doing is sorting out a section of track for it to sit on before moving into the realms of spring gear and brake gear, two major tasks judging by the drawings!   Tim |

|

|

|

Post by Deleted on Dec 30, 2014 17:33:09 GMT

a milestone reached Tim....first of many....she looks great mate...top stuff...

Pete

|

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Dec 30, 2014 17:50:42 GMT

a milestone reached Tim....first of many....she looks great mate...top stuff... Pete Thanks Pete, one thing that I noticed was that the rear set of wheels are extremely close to the drag box, did you find this with yours, I've double checked with the drawings and am confident I've done it right. Doesn't look like there is room for much movement when the springs are on. Tim. |

|

|

|

Post by Deleted on Dec 30, 2014 18:17:17 GMT

a milestone reached Tim....first of many....she looks great mate...top stuff... Pete Thanks Pete, one thing that I noticed was that the rear set of wheels are extremely close to the drag box, did you find this with yours, I've double checked with the drawings and am confident I've done it right. Doesn't look like there is room for much movement when the springs are on. Tim. Hi Tim For the life of me I can't remember...things certainly get tight under there...wait till you add the brake gear....  I did a quick search back through my build and found this image modeleng.proboards.com/attachment/download/694 ....not easy to see but you can see that the rear wheels get pretty close to the drag box.. Pete |

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Dec 30, 2014 18:43:08 GMT

Thanks Pete, one thing that I noticed was that the rear set of wheels are extremely close to the drag box, did you find this with yours, I've double checked with the drawings and am confident I've done it right. Doesn't look like there is room for much movement when the springs are on. Tim. Hi Tim For the life of me I can't remember...things certainly get tight under there...wait till you add the brake gear....  I did a quick search back through my build and found this image modeleng.proboards.com/attachment/download/694 ....not easy to see but you can see that the rear wheels get pretty close to the drag box.. Cheers for that, Certainly is tight in there, and suddenly a lot heavier now as well with the wheels on, I guess it will all be more clear to me once it's at its correct ride height. Tim. Pete |

|

|

|

Post by Deleted on Dec 31, 2014 15:11:23 GMT

"A thing of beauty is a joy to behold"..........

|

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Jan 15, 2015 9:46:43 GMT

So,I thought I'd begin this year by making a start on the brake gear. And first up are the break hangers. There are three sets, front rear and intermediates and each set is slightly different. Here are the completed front hangers. First step was to rough out the middle both sides to allow it to spring, then, to coin a phrase, use the part on a wafer method to complete everything from one side leaving the sides parallel to hold in the vice to do the same on the other side then finally screwing to a fixture to mill the outside profile.       Tim. |

|

|

|

Post by Rex Hanman on Jan 15, 2015 11:19:42 GMT

Nice! A lot of work involved there!

|

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Jan 15, 2015 11:34:03 GMT

Nice! A lot of work involved there! Thanks Rex, there was for what they are, but now I have a method and a fixture the next set should be easier and hopefully quicker. Tim. |

|

|

|

Post by Roger on Jan 15, 2015 21:15:43 GMT

Lovely work Tim. I'm finding it hard to judge the size of those, they look huge to my eyes. It makes a huge difference how I go about making something depending on how big they are. As you say, having a fixture now will speed things up no end. I do like a fixture.

|

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Jan 15, 2015 22:40:49 GMT

Lovely work Tim. I'm finding it hard to judge the size of those, they look huge to my eyes. It makes a huge difference how I go about making something depending on how big they are. As you say, having a fixture now will speed things up no end. I do like a fixture. Thanks Roger they're 3 inches long roughly . Are you still going tomorrow morning ? |

|

|

|

Post by Roger on Jan 15, 2015 22:59:03 GMT

Lovely work Tim. I'm finding it hard to judge the size of those, they look huge to my eyes. It makes a huge difference how I go about making something depending on how big they are. As you say, having a fixture now will speed things up no end. I do like a fixture. Thanks Roger they're 3 inches long roughly . Are you still going tomorrow morning ? Oh, quite large then. Mine are a lot smaller. Indeed I am, I'll be there about 11am with a good friend of mine. I'll be wearing my Model Engineering Clearing House badge but no hat or ice cream. |

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Jan 15, 2015 23:19:58 GMT

Thanks Roger they're 3 inches long roughly . Are you still going tomorrow morning ? Oh, quite large then. Mine are a lot smaller. Indeed I am, I'll be there about 11am with a good friend of mine. I'll be wearing my Model Engineering Clearing House badge but no hat or ice cream. Well I may see you then, I shall keep a lookout for the badge! I'll be there at 10ish alas no badge though. Tim. |

|

|

|

Post by Roger on Jan 16, 2015 6:47:05 GMT

Oh, quite large then. Mine are a lot smaller. Indeed I am, I'll be there about 11am with a good friend of mine. I'll be wearing my Model Engineering Clearing House badge but no hat or ice cream. Well I may see you then, I shall keep a lookout for the badge! I'll be there at 10ish alas no badge though. Tim. Ok, number logged.... mine's not on official badge, just one I made up with the logo pinched from the banner above. |

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Feb 12, 2015 8:56:33 GMT

Hi all, I've now finished the other two sets of brake hangers. Both sets were done in a similar fashion to the first type. i.e rough out both sides, finish both sides, then on to a fixture for the outside profile. Rear hangers partly done;  Intermediates roughed out;  Finish machined each side;  Onto the fixture;   There seems to be a great number of parts for stopping a tender, so It looks like I won't be stuck finding something else to get on with! Regards Tim. |

|

|

|

Post by Deleted on Feb 12, 2015 10:08:06 GMT

I thought that I had patience, but you have the patience of a Saint! Lovely stuff.

John

|

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Feb 12, 2015 10:21:27 GMT

I thought that I had patience, but you have the patience of a Saint! Lovely stuff. John I do get frustrated sometimes though, as I would like to spend a lot more time on my build than I do,but there always seems to be other things that need doing! Tim. |

|