|

|

Post by Roger on Feb 12, 2015 10:41:48 GMT

Beautiful work Tim, I'm always interested to see how the professionals hold and rough work. Very interesting.

|

|

|

|

Post by ejparrott on Feb 12, 2015 10:51:44 GMT

I thought that I had patience, but you have the patience of a Saint! Lovely stuff. John I do get frustrated sometimes though, as I would like to spend a lot more time on my build than I do,but there always seems to be other things that need doing! Tim. Ain't that the truth! |

|

|

|

Post by Deleted on Feb 12, 2015 11:58:04 GMT

Lovely workmanship Tim..first class..

Pete

|

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Feb 15, 2015 17:45:57 GMT

Just a tiny update this evening, I've managed to make the spring plates this weekend.   Regards Tim. |

|

|

|

Post by Roger on Feb 15, 2015 19:36:51 GMT

They look superb Tim, I really must pop over and take a look sometime.

|

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Feb 15, 2015 22:24:51 GMT

They look superb Tim, I really must pop over and take a look sometime. Roger you'd be more than welcome, you must bring your cylinders with you as well. |

|

|

|

Post by Roger on Feb 15, 2015 22:33:52 GMT

I might bring the whole lot!

|

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Feb 28, 2015 21:40:00 GMT

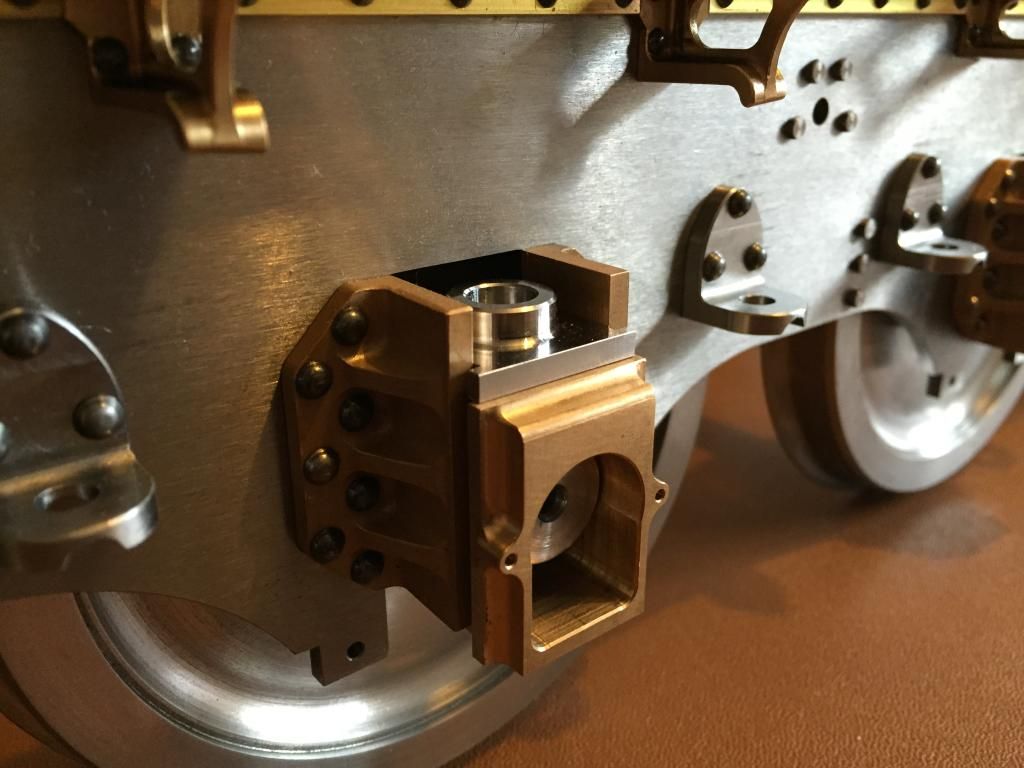

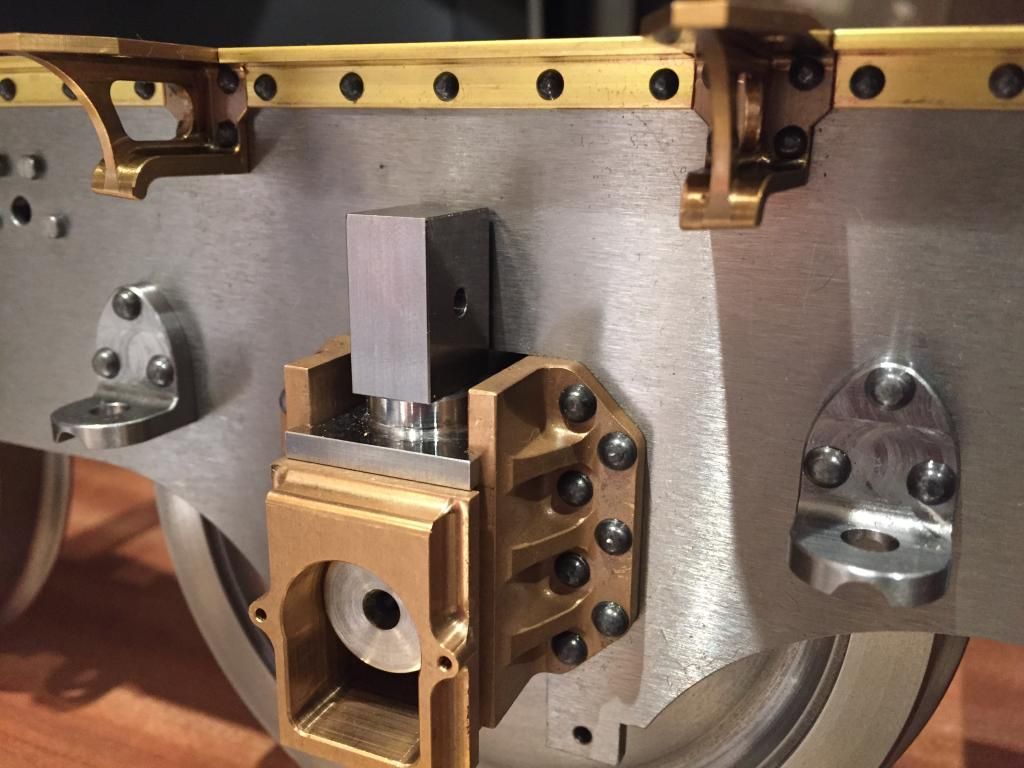

Just a small update for now as I haven`t finished these yet. These are the spring buckles. The drilled holes in the sides are the start holes for wire eroding, which is how I will be putting the square holes through them.  And just trying one in place,..  Regards Tim. |

|

|

|

Post by Roger on Mar 2, 2015 11:39:54 GMT

I do enjoy seeing your progress, the quality of workmanship is superb. A wire eroder is a handy machine to have access to, it's something I've never had the chance to play with.

|

|

|

|

Post by Deleted on Mar 2, 2015 12:38:27 GMT

Exceptional workmanship ... I never get tired of looking at the parts/progress you are making.

Cheers

Tom

|

|

|

|

Post by Jim on Mar 2, 2015 21:00:22 GMT

To be able to stand up to the scrutiny of close up photography like your work does Tim is the mark of a true craftsman. It really is awesome work.

Jim

|

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Mar 2, 2015 21:12:26 GMT

Wow, thanks for the amazing comments Roger, Tom and Jim. I really appreciate them.

Regards Tim.

|

|

|

|

Post by rogsteam1959 on Mar 3, 2015 12:59:07 GMT

Hello Tim,

how will you do the job?

Every part separate, or glue them together an all in one?

|

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Mar 3, 2015 18:59:34 GMT

Hello Tim, how will you do the job? Every part separate, or glue them together an all in one? Hi Michael, sorry I'm not quite sure what you're referring to. If you mean the spring buckles, then they will be made in 1 piece, with the square hole for the leaf springs to pass through being produced on a wire eroder. Regards Tim. |

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Apr 17, 2015 1:28:08 GMT

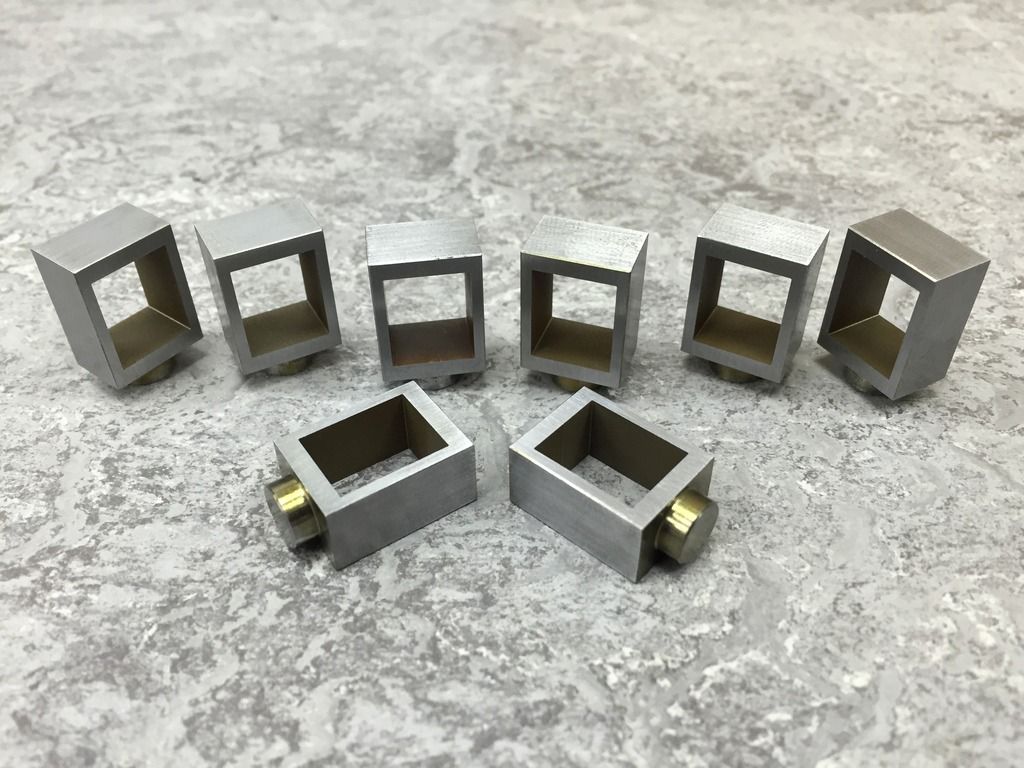

So a little bit more progress this week, the spring buckles have now been on the wire eroder to have the rectangular hole put in them, this just leaves the tapped holes for the retaining grub screw.  Regards Tim. |

|

|

|

Post by runner42 on Apr 17, 2015 8:39:02 GMT

Hi Tim,

needed to look up wire erosion to understand what you are referring to. Well that's some machine, is it part of your workshop or something available to you?

Your workmanship is excellent, producing it is one thing, preserving it during the rigours of assembly is another. You must be wearing linen gloves to keep the pristine finish.

Is it going to be a showcase or working model?

Brian |

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Apr 17, 2015 18:40:24 GMT

Hi Tim,

needed to look up wire erosion to understand what you are referring to. Well that's some machine, is it part of your workshop or something available to you?

Your workmanship is excellent, producing it is one thing, preserving it during the rigours of assembly is another. You must be wearing linen gloves to keep the pristine finish.

Is it going to be a showcase or working model?

Brian Hi Brian, firstly thanks for those kind words, The wire eroder used is one of the machines we have where I work. No linen gloves, but I do keep the tender indoors in our utility room to avoid any rust! As to what type of model its going to be, Ive not really thought that far ahead, but at the rate I`m going it will probably be an unfinished model! I`d love to see it in action though, but for now Im just enjoying making parts and whatching it grow. Tim. |

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Apr 17, 2015 18:56:05 GMT

hi tim,

spring buckles are one of the things i hate making and your's are quite superb. i dont suppose you would consider commisions? i dont know how far dave (Midland) has got with his Aspinall buckles but i havent started mine for Stepney!

cheers,

julian

|

|

|

|

Post by Roger on Apr 17, 2015 19:09:07 GMT

Hi Tim,

Superb work as always. I have a question for you about the wire eroding. How do you set up the job relative to the wire centre line?

|

|

|

|

Post by vulcanbomber on Apr 17, 2015 20:27:31 GMT

Hi Tim, Superb work as always. I have a question for you about the wire eroding. How do you set up the job relative to the wire centre line? Go back a bit and you'll see a small drilled hole in the buckles Roger, you shove the wire through the hole then touch the hole with the wire(moving the machine table) to find the edges of the hole. At least that's how the one we have at work is done. |

|