|

|

Post by runner42 on Jan 5, 2015 21:36:26 GMT

Thanks for your inputs. I am somewhat overwhelmed by the complexity of maintaining the correct water level when running a small locomotive. Added to my difficulty in grasping the issue is I don't know the start point, which is what is the maximum water level for the boiler? Intuitively it has to be below the regulator to avoid water entering the steam take off. Being a low profile dome this is going to be fairly low, so raising the water gauge top take off position will provide a longer glass but maybe not a greater readable length. I accept that going down hill may still show the water level but it may also be indicative of water entering the steam take off.

I suppose I better come to grips with these issues and establish boundaries for operation, e.g maximum up and down grades, etc.

Brian.

PS For the experienced enginemen what is the minimum amount of water over the firebox wrapper do they allow? |

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Jan 5, 2015 21:52:21 GMT

Michael

"I'm a real world engineer and as far as I'm concerned design codes are things to be treated with the greatest suspicion . Always best to design from fundamentals and then see if there is any compatability with design code . I have more than once successfully challenged twaddle published in design codes and had the codes ammended ." (sic)

Have you read the AMBSC Code to which Brian is building his boiler? I suspect not.

I too am a "real world" engineer professionally recognised for 43 years for my practical approach to solving engineering problems and complying with codes. The AMBSC Codes are to be commended because they are written in a style reflecting the BS codes of yore which gave practical outcomes. Not to be confused with the current European based stuff which requires a computer program, based on highly spurious input data, to determine a dubious outcome.

Good luck challenging the Codes.

You refer to first principles design, really. Do you do finite element analysis of every stay to sheet connection and every joint? That is where the codes come in. Sometimes the correct outcome is counter intuitive, we had a discussion on stay spacing, stay diameter and stay thickness recently. Unless the stay to sheet joint was fully understood a mistake can be made.

I have just recently seen a set of professional calculations on a boiler design by a UK designer. apart from a safety factor of 8 (where did that factor come from?) there was no allowance for copper's loss of strength with increasing temperature. coppers tensile strength at temperatures corresponding to 100 psi steam is just over half that at room temperature. Nowhere in the calculation was there a stress analysis of vital joints

|

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Jan 5, 2015 22:14:40 GMT

Brian

Grab you boiler design and set the mean water level at about half way between the crown sheet and outer wrapper, this is the mean water level; use pencil for the line. This level should be in the middle of you visible glass.

Using the point on the men water level line below you steam dome sketch in two more lines set at say 1 in 50 one rising to the front the other rising to the rear. These points corresponding to the water level going down hill and going up hill. See where these line shows on the glass. If going down hill there is not the 10% cover over the firebox crown then you have to raise the mean water level line.

FOR THE PURISTS; this is all very rough because the boiler shell is a cylinder while the firebox end is closer to a box so water levels will do funny things as the boiler is tilted up and down point.

In you favour are

1/ the Belpaire firebox with comparatively more steam space over the top than a round top fire box.

2/ Your dome and regulator are in about the middle of the boiler.

3/ Your dome is not immediately over the firebox where there is the greatest turbulence and water swell.

I suggest you look at the steam take off for the range/manifold; where located it will pick up water if the boiler level is high. I suggest the bush be blind but fed with a tube leading into the dome.

The firebox crown is high. If you are concerned talk to the BIs about putting in two arch tube circulators to bring water to the back of the crown sheet.

Regards

Ian

|

|

jma1009

Elder Statesman

Posts: 5,917

|

Post by jma1009 on Jan 6, 2015 0:09:42 GMT

hi brian,

the water gauge will show a level approx 1/4" above where it actually is. the top of the bottom nut of the gauge should therefore be just above 1/4" the level of the inside of the firebox crown. where the top of the gauge is is immaterial apart from in steam one needs to have sufficient 'steam' space' above the water level. if you have a gauge with a glass of 1/2" to 5/8" length showing between the nuts you should be ok. your boiler is very much like the LBSC Princess Marina boiler that i spent many many happy hours driving, and i do not foresee any problems with the arrangement of your fittings at all, except the silver soldering problems mentioned in my previous post.

cheers,

julian

|

|

|

|

Post by runner42 on Jan 6, 2015 5:55:52 GMT

Thanks Ian and Julian all good information.

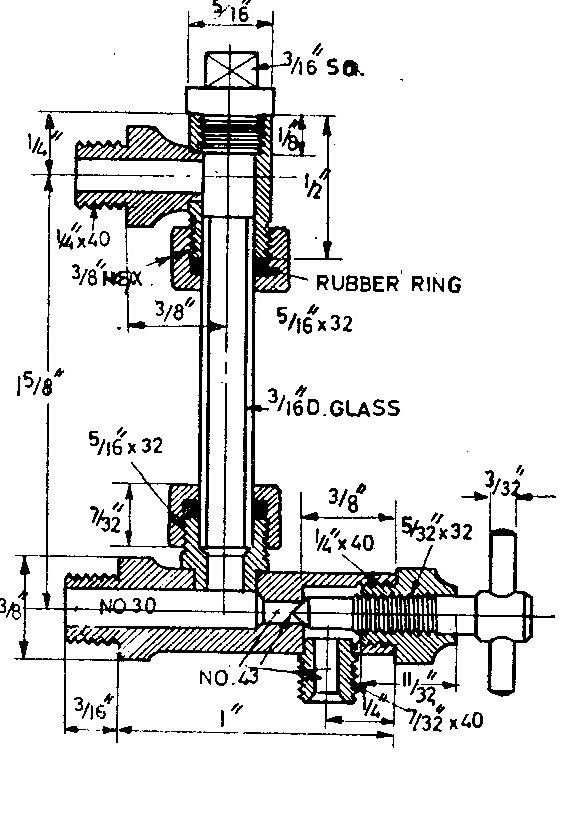

From the attached sketch of the boiler you can see that the water levels for a 1 in 50 up/down grade is reasonably OK in terms of keeping the water level over the crown in the firebox to within 10% of the distance between the inner and outer wrappers. Also with a water gauge of dimensions shown in the attached sketch positioned on the backhead will just display the water level on a 1in 50 down grade. As Ian has pointed out I have made some possibly outrageous assumptions, ie the water level pivots at the longitudinal centre point of the boiler and that the volumetric spaces forward and aft of the centre point are the same, which they are obviously not.

Brian

PS The distance between the upper and lower flanges on the backhead is 1 7/8" so it will have a longer glass than LBSC has indicated.

|

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Jan 6, 2015 8:13:13 GMT

Brian.

It looks like the mean water level could be lowered to give you more steam space and still have more than 10% coverage over the crown sheet when going down hill. Have th mean water level in the middle of the visible part of the glass.

Ian

|

|

|

|

Post by Deleted on Jan 6, 2015 15:45:53 GMT

Hi Julian ,

I think we are at cross purposes regarding SifBronze . My only mention of it being used was on failed Doris boilers . Very useful material in the right hands but definately NOT sutable for making butt joints in boiler barrels using a blowlamp !

Several people came to grief from following LBSC's advice on boiler design and construction as you probably know .

I don't live far from you and I hope to get over to your home track sometime and say hello .

Regards ,

Michael Williams .

PS: I haven't forgotten about those technical notes on steam I promised .

|

|

jma1009

Elder Statesman

Posts: 5,917

|

Post by jma1009 on Jan 8, 2015 0:19:18 GMT

hi brian,

LBSC often used to say that a half filled kettle boiled better than a fully filled kettle! the same applies to steam in fullsize and miniature! dont worry about the water level too much at this stage so long as the top of the bottom nut of the water gauge is 1/4" above the firebox crown. it is quite easy to run with the water level in the optimum position after a bit of practice.

i agree with ian that your water level on your drawing is rather high.

cheers,

julian

|

|

|

|

Post by runner42 on Jan 14, 2015 6:57:56 GMT

Thanks Julian,

it's a variation on the half glass full or half glass empty, well not really I couldn't think of anything smart to say.

Last night was a milestone the boiler inspector OK the barrel/outer wrapper and the firebox/tube assembly so he doesn't need to see it again until it's completed.

I suppose the next operation is silver soldering in the foundation ring or at least the two sides and the throat plate end. I have dry assembled the smokebox tubeplate to position the flues/tubes at the front end and also dry assembled the backhead to correctly position the firebox at the back end. Everything looks as it should, I was concerned that the longitudinal stays were going to touch the firebox crown but they are clear by an 1/8". However fitting the foundation ring has presented a bit of a problem, drilling through the outer wrapper foundation ring and inner wrapper is more difficult than I envisaged. Drilling by hand power drill, the drill binds in the foundation ring and the result broken drills are the result.

I have decided to drill through the outer wrapper and spot the foundation ring, remove this and use the pedestal drill and put it back and spot the firebox wrapper and drill through.

Brian |

|

|

|

Post by runner42 on Jan 26, 2015 6:44:42 GMT

An update. I have silver soldered the foundation ring as a means of anchoring the tube/firebox assembly. This would have been normally done iaw LBSC's requirements by fitting the girder stay in the crown of the firebox. But the code avoids the use of girder stays in preference to rod stays similar to the sides of the Belpaire part of the boiler. I also silver soldered the smokebox tubeplate. This alternative method of anchoring the inner and outer parts of the boiler has introduced a difficulty in accessing the side gap between the firebox wrapper and the outer wrapper for silver soldering the rod stays. I have access to the side rod stays only at the outside of the outer wrapper and within the firebox wrapper, the latter with some difficulty.

This picture shows the problem

The smokebox tubeplate in position

An additional problem is that LBSC required that the flues are 11/16" dia which is no longer available, instead I used 5/8" dia. Being 16 swg required by the code the ID is only 4.75" dia. This is making the ends of the super heater with 3/16" dia tubes rather tight.

Brian

|

|

|

|

Post by ejparrott on Jan 26, 2015 9:54:01 GMT

Well you've certainly done things a different way to me! I always fit crown and side stays before the firebox doorplate goes in, and the front tubeplate is always the last thing I fit!

|

|

|

|

Post by Deleted on Jan 26, 2015 11:38:03 GMT

Well you've certainly done things a different way to me! I always fit crown and side stays before the firebox doorplate goes in, and the front tubeplate is always the last thing I fit! If I had fitted the front tube plate last as you suggest instead of following the W & M, then I'm quite sure that my Brit boiler wouldn't have failed, and I'd be about £1500 better off! John |

|

jma1009

Elder Statesman

Posts: 5,917

|

Post by jma1009 on Jan 26, 2015 13:24:58 GMT

hi brian,

in my first post (31/8/14) on this thread i said that your 4 x 5/8" superheater flues would be virtually useless and advised instead 3 x 3/4" dia superheater flues with the tube spacing being re-arranged. however one set of elements of 3/16" dia in each should be ok and is the only option you now have anyway!

you will not now be able to silver solder the stays to the inside firebox wrapper. as you will not be able to ensure that the joint between the stays and inner firebox wrapper are thoroughly clean afterwards i would not even attempt to silver solder the outsides of the stays on the outer wrapper. the stays will have to be threaded and holes tapped and the stays nutted and run over with Comsol. with this method you obviously cant do this until the rest of the boiler is complete and all remaining silver soldering carried out. none of this is a problem and comsol caulked threaded and nutted stays are perfectly ok and was how everyone did them years ago including LBSC.

as the only silver soldering you can now do is the backhead and rear foundation ring, and firehole door to backhead (all of which i would do in one go), the smokebox tubeplate being silver soldered already shouldnt cause any problems, but do avoid any localised heating on this last stage (though you will have to whack the heat up to do the firehole ring to backhead which is the first bit of this last stage that i would do). you will also have to fill the firebox and firehole ring with thermalite or equivalent.

cheers,

julian

|

|

|

|

Post by runner42 on Jan 26, 2015 22:18:22 GMT

Well they were unnerving responses. I did it the way shown following a fellow member of SASMEE 7 1/2" gauge Black 5 Highlander. The only difference is the gap between the inner and outer wrapper on a 7 1/2" gauge locomotive is much greater than the 1/4" for a 3 1/2" gauge. Without the foundation ring being in place it would still be a difficult operation to place solder rings between the wrappers.

However, I shall attempt the silver soldering of the stays outside the outer wrapper and inside the firebox as I did on my 3.5" gauge Rob Roy that was a difficult but not impossible task. I will be able to see if penetration has occurred between the wrappers.

I don't understand why the smokebox tubeplate needs to go in last or be a reason if soldered (prematurely?) would be the cause of a catastrophic failure.

Brian. |

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Jan 26, 2015 22:54:11 GMT

Brian.

This is one time I would not follow Julian's advice* ; certainly not without talking to one of the BIs at the club first. If you don't feel you can go to them I can give you the name of the former BI who is very helpful. (*As always Julian's advice has merit but sound out the BIs first.)

Are you using Oxy/Acetylene or Oxy/propane for heating? if not you will need a cyclone burner to get the heat into the firebox as a normal gas burner will flare out in the confined space.

As for John (Simplyloco) I think he is referring to a boiler which failed in final construction when the LBSC inspired spelter joint between the barrel and outer throat plate gave way.

Ian

|

|

|

|

Post by ejparrott on Jan 26, 2015 23:19:57 GMT

Leaving the smokebox tubeplate until the very end allows the fire tubes to expand at a different rate to the barrel without coming to grief

|

|

|

|

Post by runner42 on Jan 27, 2015 4:13:22 GMT

Brian. This is one time I would not follow Julian's advice* ; certainly not without talking to one of the BIs at the club first. If you don't feel you can go to them I can give you the name of the former BI who is very helpful. (*As always Julian's advice has merit but sound out the BIs first.) Are you using Oxy/Acetylene or Oxy/propane for heating? if not you will need a cyclone burner to get the heat into the firebox as a normal gas burner will flare out in the confined space. As for John (Simplyloco) I think he is referring to a boiler which failed in final construction when the LBSC inspired spelter joint between the barrel and outer throat plate gave way. Ian Thanks Ian,

that is a valid point on the propane burner flaming out in the small confines of the firebox, but this would be the case if I had managed to place the silver solder rings between the wrappers. Now that you mentioned it I used oxy-propane to locally heat the rod stays in the firebox for Rob Roy. I don't have oxy-propane available I could get a local radiator repair workshop to do that for me.

Brian

|

|

|

|

Post by runner42 on Jan 27, 2015 4:27:41 GMT

Leaving the smokebox tubeplate until the very end allows the fire tubes to expand at a different rate to the barrel without coming to grief Thanks Ed a point to ponder. Let me say that isn't the expansion mainly in a linear manner and since the barrel and the flues/tubes are of a similar length then the expansions will be similar and the nett effect very little? That's of course if the temperatures are the same and the parts heated at the same rate, which of course is difficult to control. What type of failure should I look out for?

Brian

|

|

steam4ian

Elder Statesman

One good turn deserves another

One good turn deserves another

Posts: 2,069

|

Post by steam4ian on Jan 27, 2015 6:37:41 GMT

Thanks Ian,

that is a valid point on the propane burner flaming out in the small confines of the firebox, but this would be the case if I had managed to place the silver solder rings between the wrappers. Now that you mentioned it I used oxy-propane to locally heat the rod stays in the firebox for Rob Roy. I don't have oxy-propane available I could get a local radiator repair workshop to do that for me.

Brian

There are members of the club who I am sure would help; we have an Oxy/Acetylene kit at the club which doesn't get a lot of use. Ian |

|

|

|

Post by ejparrott on Jan 27, 2015 9:34:49 GMT

Leaving the smokebox tubeplate until the very end allows the fire tubes to expand at a different rate to the barrel without coming to grief Thanks Ed a point to ponder. Let me say that isn't the expansion mainly in a linear manner and since the barrel and the flues/tubes are of a similar length then the expansions will be similar and the nett effect very little? That's of course if the temperatures are the same and the parts heated at the same rate, which of course is difficult to control. What type of failure should I look out for?

Brian

Copper expands at a rate that's fixed yes, but consider what happens when a flame is directly impinged on the barrel tube, that receives masses of direct heat, while the tubes receive radiated heat as it pass through the barrel tube and the air space. The end result can be, but doesn't always happen, twisted tubes or firebox/smokebox tubeplate joints pulled. It's not something that's guaranteed to happen, and it seems to be the bigger boilers that suffer. The key thing for you will be to bring the whole boiler evenly to temperature as slowly as you can, as quickly as you need to. I've only ever seen it once, but buy the sounds of it it's happened to John, but I don't recall seeing that one |

|