|

|

Post by Oily Rag on May 7, 2017 21:46:42 GMT

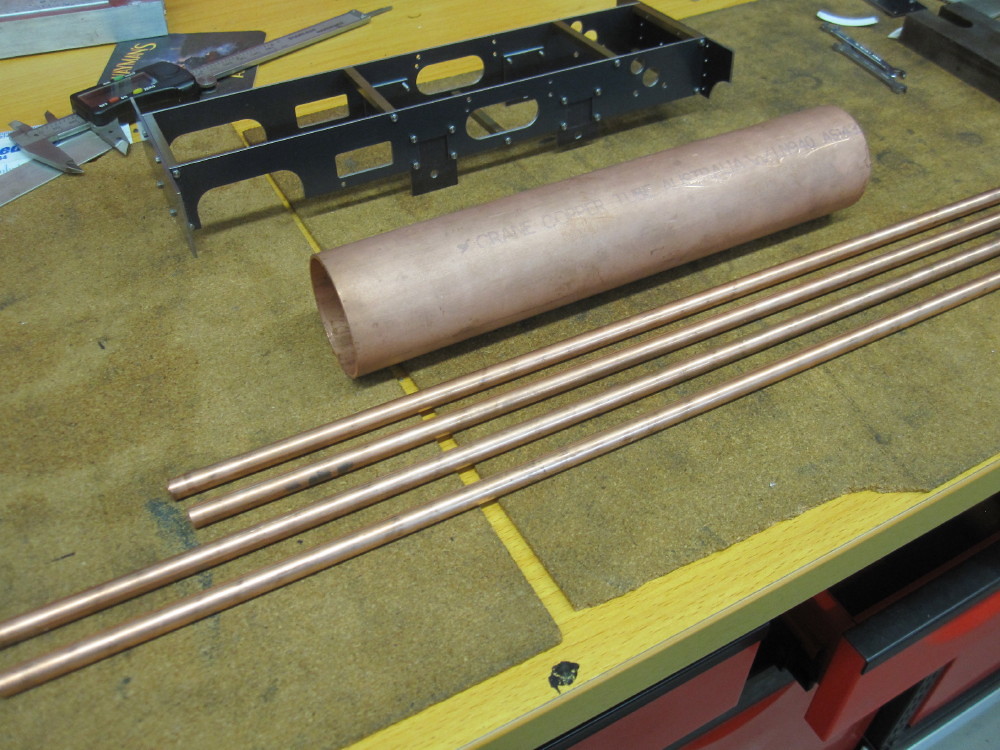

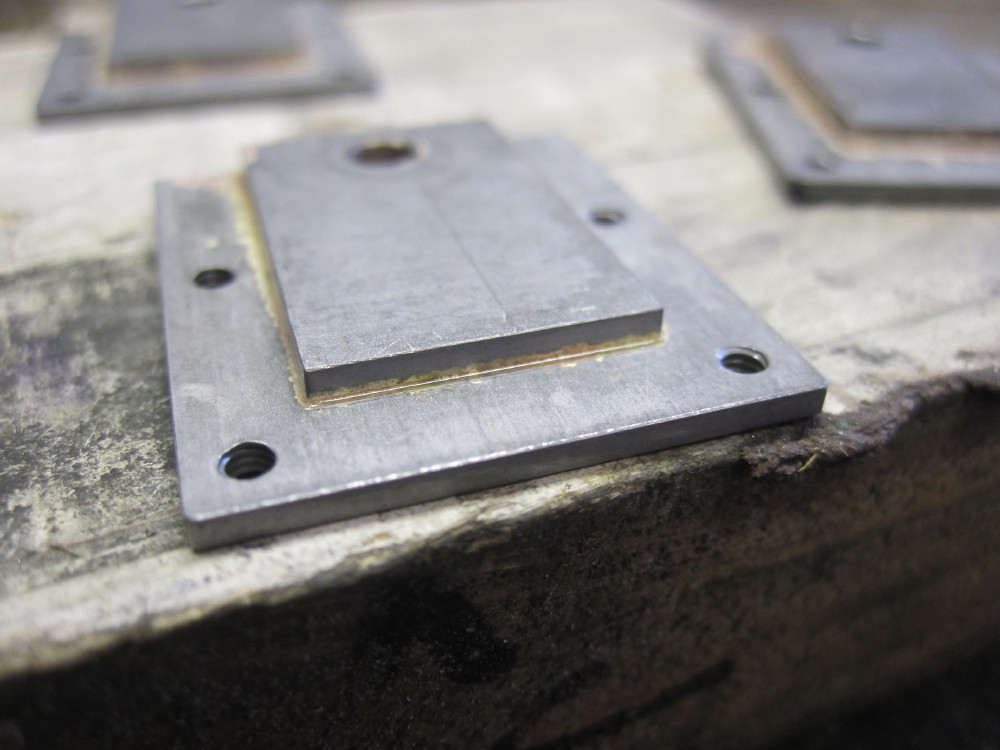

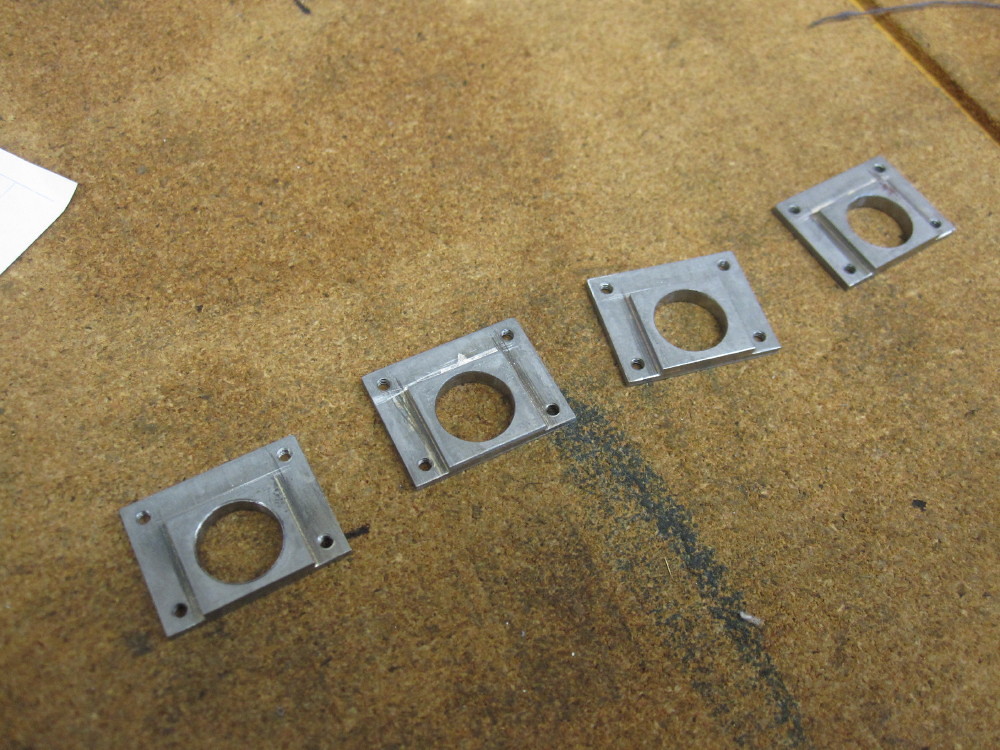

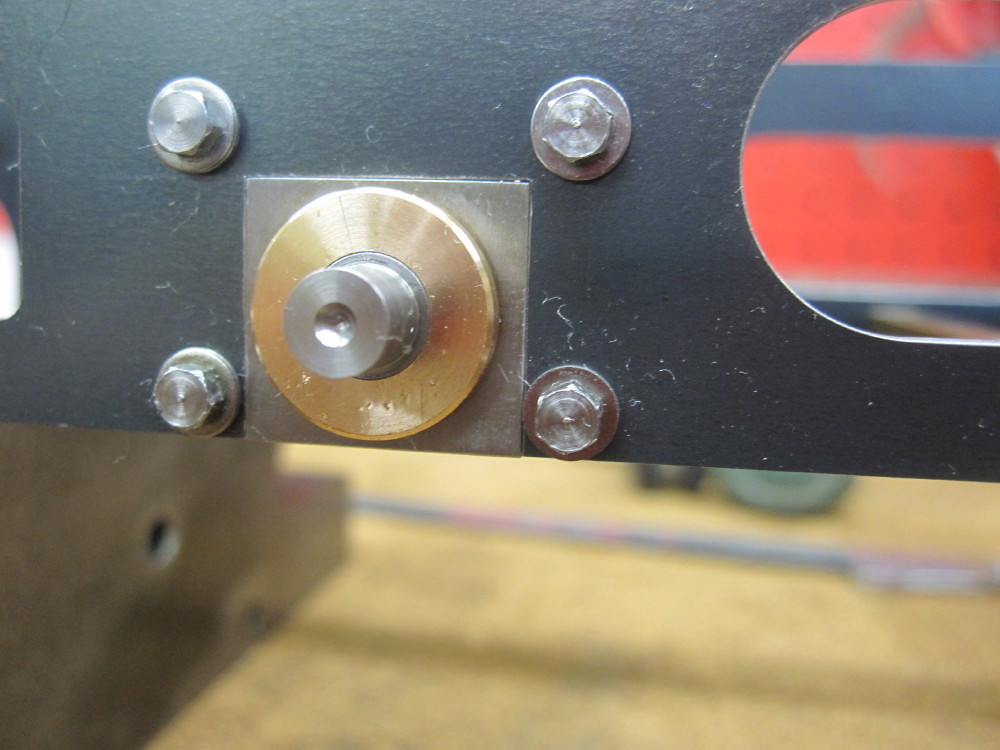

A whole day in the Red Room, YAY! Boiler material arrives, bad brain bad brain, forgot the 2mm copper sheet.  Brazed up the axle bush holders, not really axle boxes.  Out came the boring head. I am new to the boring head but I am liking it so far! 11.00mm holes  Bronze bushes and Silver steel axles, had to run them into free them up after the 1/4" Reamer was run through, Silver steel in the tailstock with the faintest touch with a small chisel to lift the surface and then I rubbed it done with 1000 grit. Oil and passed in gently into the bush (still in chuck) and a sexy sliding fit was my result. Now when it is all bolted up into the frames we will see if it still turns?  |

|

|

|

Post by Shawki Shlemon on May 8, 2017 7:53:59 GMT

May I ask where did you get the boiler barrel from ?

Thanks

|

|

|

|

Post by Oily Rag on May 8, 2017 21:52:34 GMT

May I ask where did you get the boiler barrel from ? Thanks E and J Winter. Ben, the new owner is pleasant to deal with and most helpful. |

|

|

|

Post by Oily Rag on May 8, 2017 21:58:44 GMT

|

|

|

|

Post by keith1500 on May 9, 2017 5:55:28 GMT

Sans washers? What are sans washer?

Keith

|

|

|

|

Post by springcrocus on May 9, 2017 7:39:47 GMT

French for "without washers"

Steve

|

|

|

|

Post by Oily Rag on May 10, 2017 21:34:29 GMT

The Red Room gets the monthly clean over. Lathe and Mill cleaned and oiled.

2 hours!

MAM made a brilliant Taco meal while I was scrubbing :-) Of course, the next task was the kitchen clean up.

You have got to love an epoxy sealed floor. It dries in an hour after mopping up. I wish my bike making workshop was sealed.

|

|

|

|

Post by Oily Rag on May 10, 2017 21:50:58 GMT

Simple things on my journey. I am terribly slow, but nailing the accuracy is my goal. I want to get the accuracy of my skills and understanding uplifted, so when I return the 5" gauge 060 Loco I am confident and faster. Then when I move onto #253 as delivered in 1920 I will much along the time line of metal working knowledge. (a 5" QR Beyer Garratt beckons after that if I live long enough)

The axles (silver steel) are done, they pass into the bushes with not a hint of a fiddle, I was very pleased. There was barely a hint of binding in the lead axle, but nothing to worry about.

The axle ends are not centre drilled as the crank shoulder is just 5mm long and the drawings call for pinning, so drilling for the pins would break into the #1 centre drill hole. So I spot drilled the ends for the purposes of mounting in the quartering jig later. All of this is not mentioned in the book.

|

|

|

|

Post by Oily Rag on May 10, 2017 21:53:34 GMT

With a clean workshop, clear minds, the workshop techs contemplate the approach.

"There are some wheels in there."

|

|

|

|

Post by Roger on May 10, 2017 23:21:36 GMT

I think you're taking exactly the right approach to making things. Clock everything up, measure accurately using a micrometer on the lathe, not a vernier, and approach finished sizes with equal cuts so you know what spring you're going to get. If you take your time, like you're doing, the results speak for themselves. You're making a cracking job of those parts.

|

|

|

|

Post by Oily Rag on May 11, 2017 23:16:48 GMT

Last night, after a glass of Shiraz and then some contemplation of the approach, the blanks were hacked down on the Blue Lathe in the bike room. They will now go to the Red Room for the delicate work in the Myford on their path to becoming 32mm gauge wheels. There is no reference of the back to back dimensions in the book which I think is a big miss, but I got that sorted out.

|

|

|

|

Post by Oily Rag on May 11, 2017 23:30:30 GMT

I think you're taking exactly the right approach to making things. Clock everything up, measure accurately using a micrometer on the lathe, not a vernier, and approach finished sizes with equal cuts so you know what spring you're going to get. If you take your time, like you're doing, the results speak for themselves. You're making a cracking job of those parts. Thanks Rodger. Your encouragement is very much appreciated and your notes of "approach finished sizes with equal cuts" and "like what you're doing" is spot on. For me it is about the journey. A bit like a train journey. The journey is enjoyable. It has been many years of waiting to express my self in metal work via model engineering. Making bikes, travel, racing, work with cycling teams, has all delayed this. When my body slowed my work up, I did the CAD drawings of #253 from the works drawings, knowing it will be some time before I can start it, but I can knock over most of the design. This is why I am "excited". The time is now to progress and move towards the visions I have. MAM (Mary Ann) urges me to get stuck in. For me a few laps on the track will be fun on the locos I make, but for me is the journey of making I really enjoy. I do like firing full size steam locos so my footplate needs are sated there. (well when #720 is back in steam and when Gympie gets going again) I am working with a chap with investment casting projects that will later also enter into my model engineering. More aspects of the journey. OK, I am not Cherry Hill, Bill Carter or such like, but I want to constantly refine my work. I find your metal work inspiring. I reckon a CNS mill is going to land in the next 5-7 years, when I am ready to appreciate and utilise it. Cheers Dazza |

|

Lisa

Statesman

Posts: 806

|

Post by Lisa on May 12, 2017 5:59:43 GMT

There is no reference of the back to back dimensions in the book which I think is a big miss, but I got that sorted out. It was also omitted from the Edwin construction series in AME, it wasn't until quite late in the series that they put a bright yellow box at the top of the page with the back to back measurements (29mm for 32mm gauge, 40mm for 45mm gauge), apparently a lot of people were asking. I've got a couple of Edwin chassis, originally was going to build them to sell, in hopes of funding a lathe... might still do so to fund a blowfly boiler. The recent AME articles on coal fired small scale boilers certainly make these little loco's look more interesting. |

|

|

|

Post by Oily Rag on May 12, 2017 21:02:26 GMT

There is no reference of the back to back dimensions in the book which I think is a big miss, but I got that sorted out. It was also omitted from the Edwin construction series in AME, it wasn't until quite late in the series that they put a bright yellow box at the top of the page with the back to back measurements (29mm for 32mm gauge, 40mm for 45mm gauge), apparently a lot of people were asking. I've got a couple of Edwin chassis, originally was going to build them to sell, in hopes of funding a lathe... might still do so to fund a blowfly boiler. The recent AME articles on coal fired small scale boilers certainly make these little loco's look more interesting. Lisa, yes I saw that back to back yellow box notes in the AME series and some letters to the editor etc. I have those back copies of AME. I have recently let my subscription lapse on AME mag. I was tired of pages and pages of run day and event pictures. I know some enjoy this but I find it useless to have pics of run days. Errr Yuk. (Dazza technical term) I can go to Warner and see run days and the drive or ride on my bike is only 10 minute. I know the mag is at the mercy of good articles being submitted, maybe one day I will submit an article before I go belly up. I get ME and EIM although I am about to chase EIM up as March and April mags have not arrived but May has. Another mate of mine has the same problem. |

|

Lisa

Statesman

Posts: 806

|

Post by Lisa on May 13, 2017 7:31:17 GMT

I'm one of those that enjoy reading/seeing the running day articles and photo's... not being able to get to a club, it's nice to see what's going on around the place. I was less interested by them when I was a regular at various tracks though. I recently looked into rejoining QSMEE (thinking of access to a boiler inspector), but not being able to get there means I can't even get the form filled out, so never mind.

Dad likes looking at the pictures, so I subscribed to AME last year, and have just resubscribed. I've got every issue from No. 1 up to about 2004, then a bit of a gap with just occasional issues until recently. One of these days I'll hopefully be able to pick up the missing ones to complete the set.

|

|

|

|

Post by Oily Rag on May 14, 2017 20:31:11 GMT

Lisa, fair enough regards AME. Perhaps I am becoming cantankerous after subscribing from issue # 1.

I look forward to seeing your blow fly in steam. Nice story to follow!

Cheers Dazza

|

|

|

|

Post by Oily Rag on May 16, 2017 21:54:52 GMT

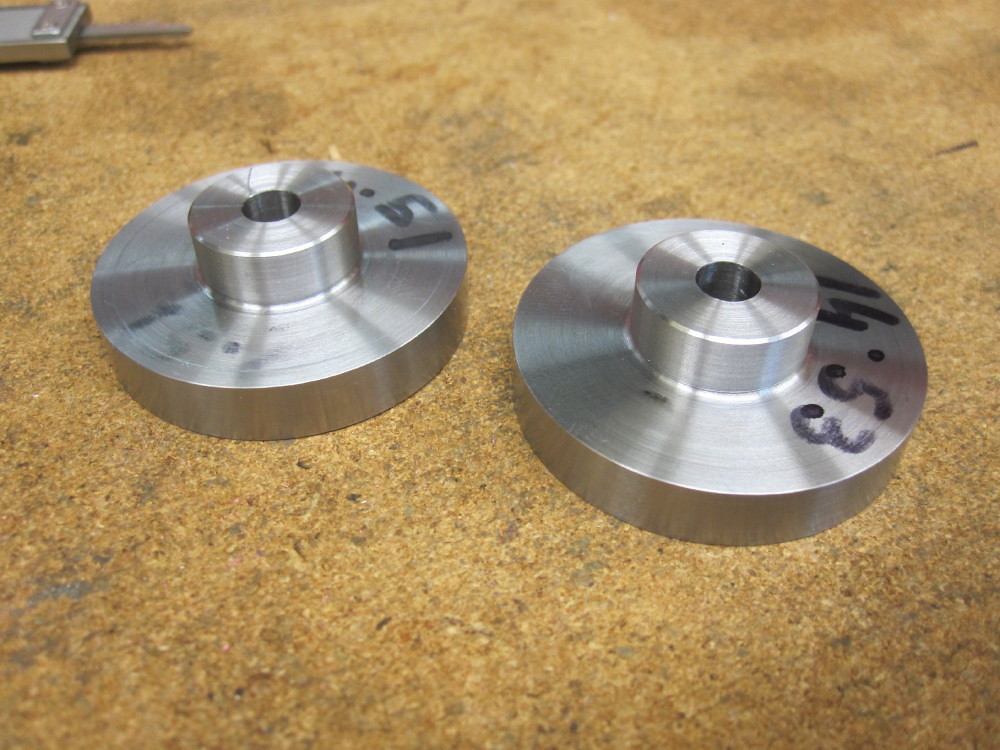

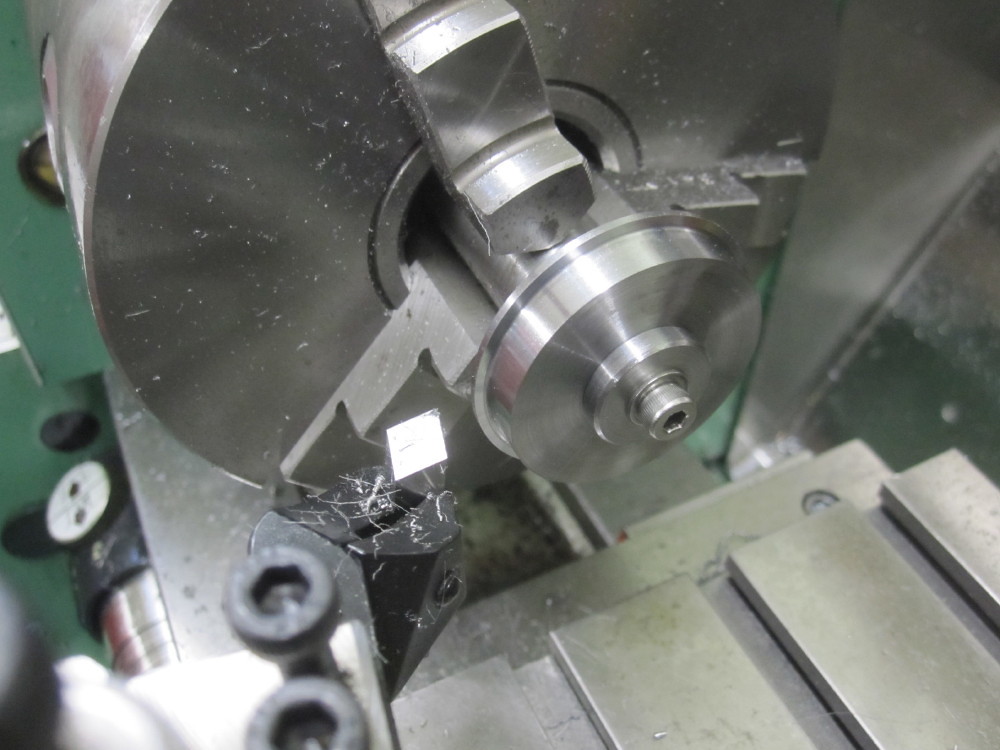

Wheel blanks all within .002mm Pondering the tread attack. It has been 20 years since the last 5" loco wheels, but these are smaller at 42mm diameter. I completed the ends of the wheel blanks and then turned a spigot with M4 thread and washer for the tread machining. Pondering the tread attack. It has been 20 years since the last 5" loco wheels, but these are smaller at 42mm diameter. I completed the ends of the wheel blanks and then turned a spigot with M4 thread and washer for the tread machining.

I am very much enjoying my evenings in the Red Room. ABC Jazz playing in background on the radio. Nice tooling, away from the bike making toil area.

|

|

|

|

Post by Roger on May 16, 2017 22:20:20 GMT

Nice work, but I think you mean 0.02mm, looking at the figures on the wheels?

|

|

|

|

Post by Oily Rag on May 17, 2017 2:44:09 GMT

Nice work, but I think you mean 0.02mm, looking at the figures on the wheels?

Whoops. yes of course 0.02mm

my typo, bad brain bad brain

I would be in fantasy land if I was thinking I can split a hundredth of a millimeter into 5 parts! |

|

|

|

Post by Oily Rag on May 17, 2017 22:26:21 GMT

Dazza got some time in the Red Room last night. Wheels progressed. 0.5mm radius in the flange root and 10 degree taper to the flange as per the full 16mm(SM32) wheel profile .

All went well.

Onto the next profile ops later this week.

Tonight there will be no Red Room action as we are all off to see Mary Ann become an Aussie citizen so she can honestly cheer for the Aussies at the Ashes !

|

|