rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Jan 27, 2017 8:41:01 GMT

Good Morning Gentlemen and Ladies.

This is my first post, so bear with me.

I am about to commence the build of the 5 inch gauge Hunslet locomotive.

The castings are from Reeves. The boiler from Western Steam.

On the Model Engineers Laser website they list various parts for the 5" Hunslet.

Can any forum members explain why several items are "ID 3 15/32 not 3 1/4"

Reeves tell me that their main frames are not spotted. I am waiting MEL to tell me if theirs are.

Are reeves and MEL parts compatible and interchangeable.

Regards

|

|

smallbrother

Elder Statesman

Errors aplenty, progress slow, but progress nonetheless!

Errors aplenty, progress slow, but progress nonetheless!

Posts: 2,269

|

Post by smallbrother on Jan 27, 2017 9:39:19 GMT

Hi rrmrd66,

The dimensions you refer to are for the saddle tank which is a long way off down the line in the build process. By the time you get near that stage you will see what effect the change in dimensions will have. It sounds to me there will just be an extra bit of space above the boiler - maybe take the opportunity to add more insulation? I don't think it will look any different from the outside. The brackets holding the saddle tank in place may need a minor change in dimension too.

I am using drawings and parts from Reeves/Model Engineers Laser/GLR Kennions and Ebay for my Juliet. They are all in accordance with drawings so far.

Pete.

|

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Jan 27, 2017 12:42:53 GMT

Hello smallbrother/Pete

Thanks for your rapid response.

Malcolm High, at MEL, has confirmed that the modified dimensions are, as you suspect, to give greater clearance around the boiler for insulation etc and to accommodate a cab that a customer of his has designed.

Incidentally, their main frames are spotted as I am sure you will know. Reeves told me that theirs are not.

Would I be right in thinking that spotted frames make the build a bit easier?

I appreciate that I may be a bit forward in thinking about boiler details, before I have struck a blow, but the lead time on a 5" Hunslet boiler is 18 months so I wanted to be sure before placing an order.

Any other 5"gauge HUNSLET builders out there who would care to share their build experiences with me?

|

|

|

|

Post by Deleted on Jan 27, 2017 14:40:35 GMT

Hi

I would go with Malcolm for the frames, or for that matter, any laser cut parts....my A1 frames are from Malcolm, there was a slight error on the horn stay slot cut in the frame but nothing that couldn't be put right. I believe that Malcolm has corrected this now, in the meantime he supplied two types of horn stays, one to fit drawing and one to fit frames with the error as it wasn't detrimental to the operation of the model.

Now regarding Reeves, I also had a set of their frames for the same loco, this was an xmas gift, they were unusable due to the positioning of one of the lightening holes that had been cut right where the star stay bolted to the frames. Yes Malcolm's frames are partly spotted for the holes, well my A1 was probably about 50% spotted, spotting was very accurate although I didn't use the horn spots as I preferred to transfer the holes from the horns themselves once happy with positioning.

regards

Pete

|

|

dscott

Elder Statesman

Posts: 2,440

|

Post by dscott on Jan 27, 2017 21:14:00 GMT

I have been building 2 of them for too many years!

As drawn it is too complex and many things wrong.

The frame stretchers in full size are straight and no cut outs for the boiler!

The weighshaft has 2 bolts not 5 and is easier to make!

The brake is by the frames and the reverser is outside.

The draincocks lever is a simple 1/4 X 1/16 rod with a bolt or tiny handle in the cab!

Not the complex quadrant shown!

I did a boiler from 6" diameter pipe!

And several more!!!

David.

|

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Jan 28, 2017 10:27:34 GMT

Hello David Ref your remark "The frame stretchers in full size are straight and no cut outs for the boiler!" Have a look at this guys comments on: ww3.tiki.ne.jp/~hwata/e-Hunslet_201109.htmIt is the last picture on the page Is this what you mean? Thanks for the assistance |

|

dscott

Elder Statesman

Posts: 2,440

|

Post by dscott on Feb 1, 2017 20:01:54 GMT

Yes for the rear stretcher just behind the wheels but for the valve plate you can cut it shorter

and machine spring shackles as per full size to bolt in place.

I have one as per drawing for the steam chests, and one the same as he shows with a sandwich piece

adding useful weight even for one of these!!

David.

|

|

dscott

Elder Statesman

Posts: 2,440

|

Post by dscott on Feb 1, 2017 20:32:12 GMT

Yes, a thousand photos saves 100 words.

Thank you what an enjoyable evening!

I got as far as the opening windows. Yes, I sat through his William series making a silk

purse etc!!

Yes going through everything has been thought through including the thickness of the frames

at 9 mm to save horn blocks! But do go for split axle boxes as these when worn can just be replaced!!

I think my boilers will have to go to Western Steam as they are very big for garden heating in the right

places!

David.

|

|

|

|

Post by Roger on Feb 2, 2017 13:13:25 GMT

You might want to ask the moderator if you can move this into the General Chat page where all of the other builds are. I don't think this is really the right place.

|

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Feb 2, 2017 15:12:59 GMT

Gosh! My 4th post and already Proboards Royalty is commenting upon my question.

If I am lucky I might get Julian soon as well.

Yes Roger you are right. How do I do it?

I had intended to build Speedy as my first build but you two have frightened me off.

Fascinating thread though. Keep up the good work.

If there is a moderator looking at moving me could he also tell me why some threads seem to start and run forwards and yet others run(date wise) backwards, or is it just me?

Thanks for all the useful tips David

|

|

|

|

Post by ilvaporista on Feb 2, 2017 16:31:50 GMT

I've got a half built one lurking under the bench, I bet you will steam yours before I get round to finishing mine.... I sort of tailed off at the boiler making phase but Roger's build has got me all fired up again and it might even see the light of day for another spurt of building. To then go back to a gentle slumber for another few years.

|

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Feb 2, 2017 19:42:19 GMT

Hi David,

Yes I agree with Roger this should be moved to 'General Chat'.

I know the Don Young 5"g Hunslet quite well.

I think the issues you raised are largely immaterial. Whatever option you go with, it is quite a straight forward design with no pitfalls, and the Don Young design is excellent.

Dave has pointed out discrepancies, but to be honest there were lots of discrepances in fullsize too.

None of the existing 'Quarry' Hunslets that survive are identical, and you might like to consider 'Rough Pup' in the Museum of the Talyllyn Railway at Tywyn which is as the loco left service at Dinorwic.

The Milner design is quite another kettle of fish, and far inferior to Don's design.

All of Don Young's Stephensons gear locos have errors in them, as he did not properly understand this gear. When you get to the valve gear a few modifications and improvements will be very worthwhile for performance.

I think that drilling the frames and profiling same ought to be very straightforward, and will also be helped by the early issues of LLAS for the construction series.

Cheers,

Julian

|

|

|

|

Post by Roger on Feb 2, 2017 20:43:50 GMT

Gosh! My 4th post and already Proboards Royalty is commenting upon my question. If I am lucky I might get Julian soon as well. Yes Roger you are right. How do I do it? I had intended to build Speedy as my first build but you two have frightened me off. Fascinating thread though. Keep up the good work. If there is a moderator looking at moving me could he also tell me why some threads seem to start and run forwards and yet others run(date wise) backwards, or is it just me? Thanks for all the useful tips David Hi David, Steady now, I hardly think 'Royalty' is appropriate.... persistent and dogged perhaps. I'm sorry if I've put anyone off making a SPEEDY, mine might have started off as that, but the plans more or less went in the bin a few weeks after it was started. I'm pleased it interests you though. If you look for 'Tel' in the Members list and send him a private message, I'm sure he'll do it if he can. |

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Feb 2, 2017 22:28:07 GMT

Bingo.

Julian of the Valleys as well now. What a week.

No its not David

My name is Malcolm.

I was thanking David Scott.

I will contact Tel. I do not know why my initial question ended up ME Club info??

Will be back with updates as I progress.

|

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Feb 17, 2017 10:30:18 GMT

Good morning all

At long last and two messages to the administrator ( does this forum only have one? can the old hands advise please) I have now been moved from ME Club News into General Chat as per Rodger's and Julian's advice. Thanks for the tip.

It has taken me a couple of days to actually find my thread. Hopefully now we are up and running.

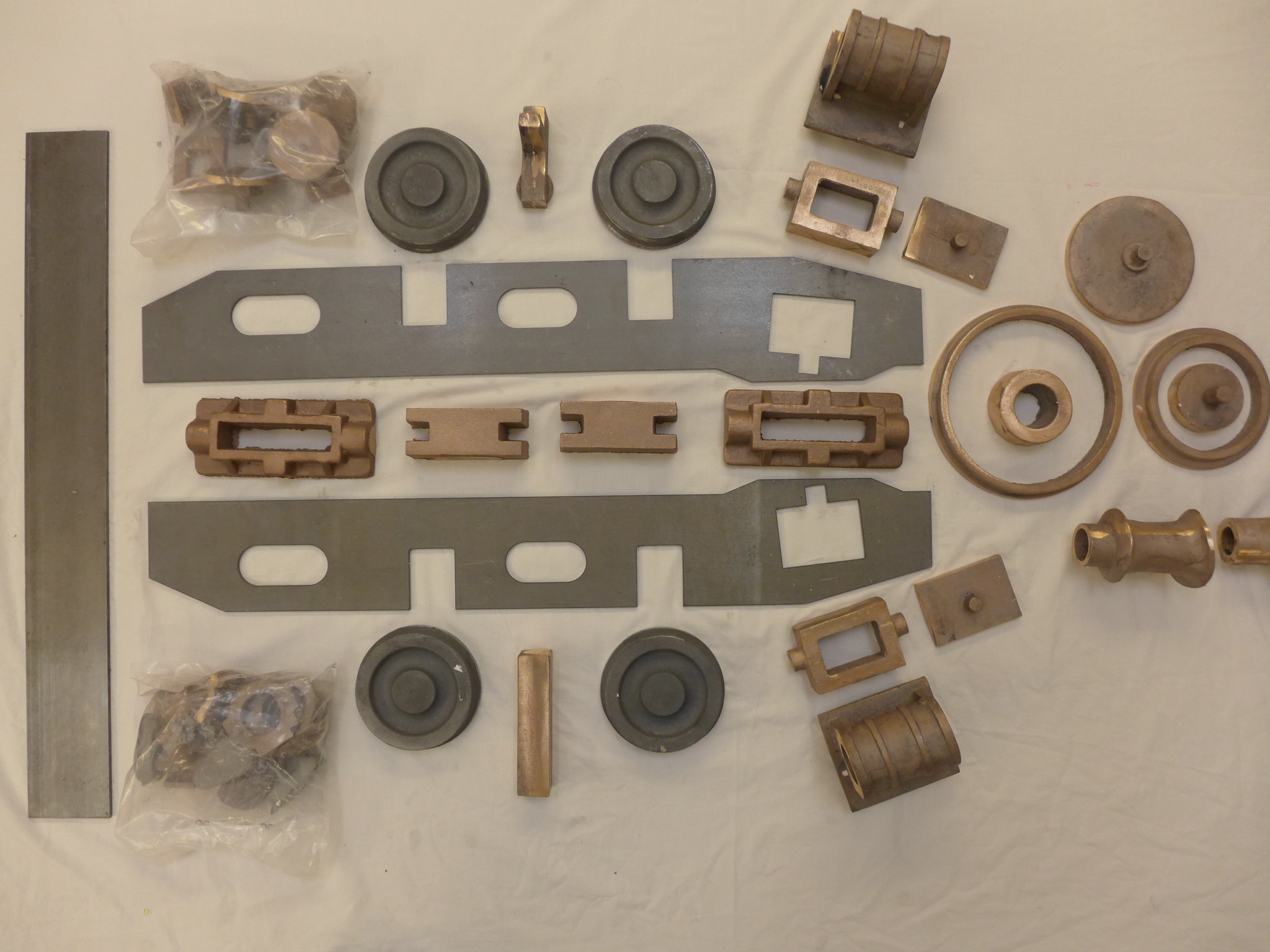

Large pile of castings arrived from Reeves a couple of days ago, minus the wheels which will come on later.

Tube of drawings, in much more detail than I feared, also with the castings. ( I somehow thought the little thumb nails on the Reeves website was all you got! Remember, this is my first ever steam engine).

I note than Don Young's drawing dimensions are without tolerances. Are most of the fits down to common sense?

I am trying to finish off an eight day weight driven clock and oak cabinet (John Wilding for the horologists amongst you) and then I can get going on the Hunslet.

My new milling machine from Warco, purchased at "Ally Pally" exhibition should arrive in the next week or so.

I have opened an account on Photobucket and will post a picture of the metal working side of my workshop prior to reporting on the Hunslet build by a first timer.

Cheers

Malcolm

|

|

|

|

Post by Roger on Feb 17, 2017 12:39:25 GMT

Hi Malcolm,

Welcome to the other side...glad you made it across.

I don't know what Don Young's drawings are like, but don't assume that drawings are without errors even though they've been kicking about for years. Nothing gets updated, so I'd do a comprehensive search for 'errors on drawings' here and ask others who have made your locomotive.

I've never seen tolerances on any Model Engineering plans to date, it's up to your judgement or wordy descriptions in any 'words and music' that you might find from the author of any instructions. Descriptions like 'sliding fit' are the best you're likely to get as a hint to what you might need. Since you're and Engineer, you'll figure out what's sensible and what isn't.

Don't be a slave to the plans, there are some really poor design details on the plans I have. Treat them as just one way of doing things, and if you've got a better idea, then do that. The materials and fixings will date back to pre-Metrication days, so materials will have been selected from what was available. I take no notice of any of this, using Metric threads (coarse and fine) and Metric materials since they are readily available. Any scale detail will have been rounded to the nearest Imperial size, so don't assume that anything is accurate to scale.

I only take the barest of information from my plans, I do my own thing to make it look more like the real thing and use modern sealing methods such as 'O' rings which didn't exist when the design was published. I find it a lot more satisfying to modify parts or just start again. It all depends on how much work you are prepared to put in for the end result that pleases you.

|

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Feb 18, 2017 0:25:20 GMT

Hi Malcolm,

I dont think you should encounter any drawing errors. Don kept the master drawings and updated them if any errors occured from feedback from builders.

I you want to get a better valve gear then give me a shout when you get to this stage. There are a few errors in the Don Young valve gear that offend purists like myself.

Cheers,

Julian

|

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Feb 19, 2017 20:23:12 GMT

Hi Roger and Julian

Thanks for your replies.

I look forward to more of your seeds of wisdom in the future.

Regards

Malcolm

|

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Apr 1, 2017 15:07:27 GMT

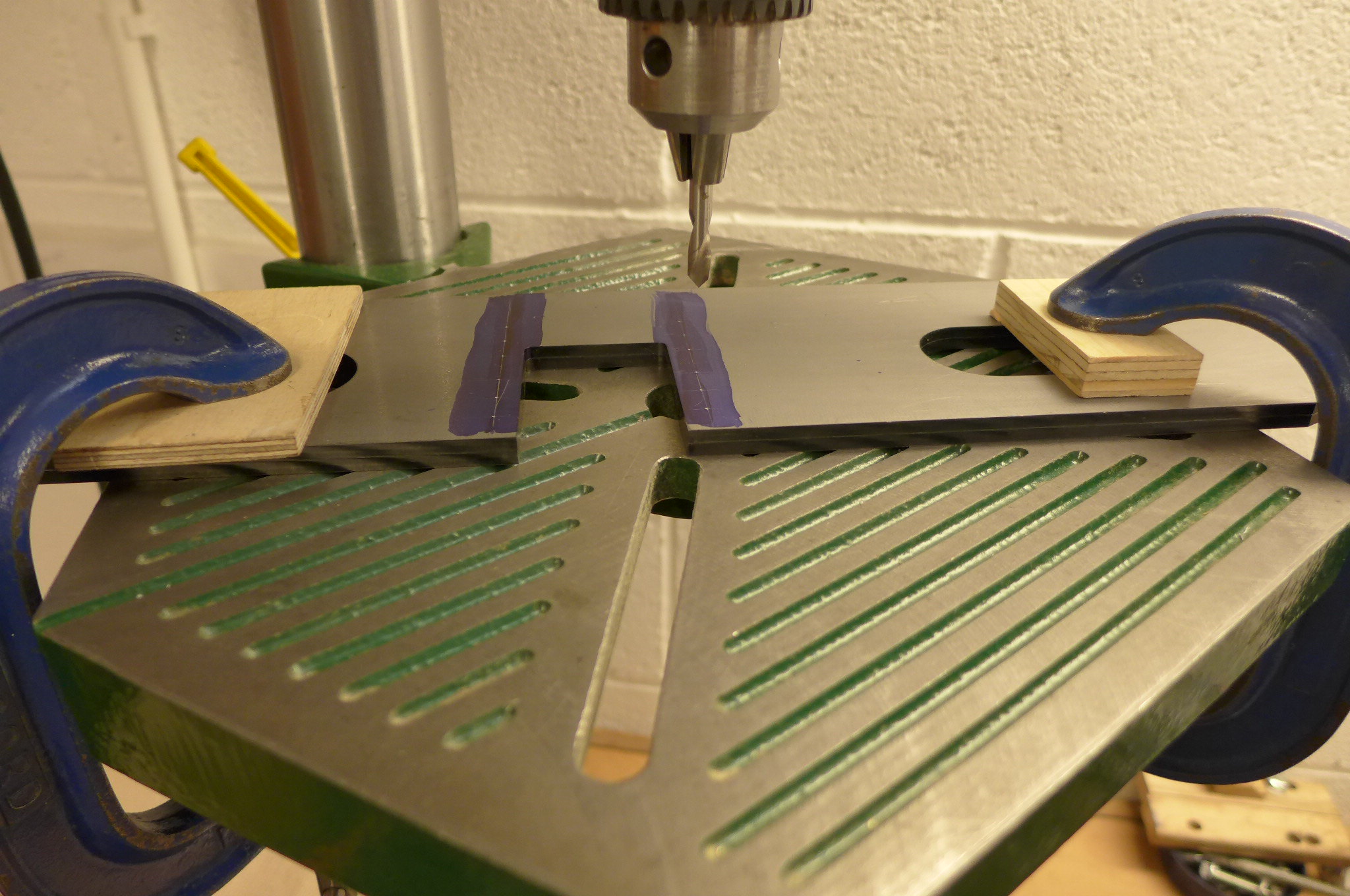

Good Afternoon everybody. I imagine those of you who read my first attempt at joining this forum back in February have already put me down as a "flash in the pan" or one of those guys who starts a thread and then disappears into the ether. Not so, I am afraid. Here I am back and slowly getting on with the build of the 5"gauge Hunslet. A short preface here is I think worthwhile. I am a retired Mechanical engineer, of a "certain age". My engineering CV reads like this. Tool Making apprenticeship, High Speed can making machinery engineering, Rolls Royce gas turbines (Concorde and Harrier), Dynamic Balancing Machines, Hydraulic Sealing Systems, oil,coal,steel,military,mobile hydraulic (excavators/fork lifts etc) Engineering and other bits and pieces. I ran a company of 30+people for more than 30 years. So,in a word I have been around a bit and always involved in engineering problem solving. Upon retirement I went part time to Leeds CAD and did cabinet making (G&G) as I was building a new house, but that's another story. One of my chums gave me his fathers Myford lathe ( not quite as old as me) with a pile of clock makers tools. So I said to myself I will make a grandfather clock ( how difficult can it be!) plus the cabinet. This took me about 12 months and is now up and running. All this time I was reading about the magic of turning hot water into forwards motion and joined this forum. I have got to tell you that I am in awe, and somewhat terrified, by the level of knowledge that most of you have. Most of what you discuss is foreign to me. It is quite easy to be put off by all this knowledge, so take it easy all you elder statesmen and think about us new boys. What I ask myself if someone like me wants to start from scratch and build a steam engine? Well, I will attempt to convey all the things I learn along the way in the hope that other new starters will be able to learn from my mistakes. I have chosen a 5" gauge HUNSLET a) because it is relatively simple and b) because I have a connection with Hunslet Leeds in that in 1971 I was "rationalised" and moved from the Midlands to Yorkshire to a company in Moor Lane, Leeds.Just around the corner I often used to pass Jack Lane and I remember seeing what must have been the very last narrow gauge steam locomotives they built. The main reason why I have taken so long to get going is that I have had "issues", as they say ,with equipment. I hope to get this resolved shortly and will report accordingly in the "in my workshop" thread. OK, lets begin now with the regulation picture of all the parts. Purchased as job lot from Reeves. New model engineers beware. Making steam engines is not a cheap hobby!  P1010052 P1010052 by Malcolm HARWOOD, on Flickr I purchased reprints (very dark and black) for Reeves that I believe came from a magazine called "Locomotives Large and Small". Referred to by those that know as "LLAS" This long running series of chapters has the advantage that they were written by Don Young, the designer of the Hunslet engine. The tube on the right of the above pic is for the 6 sheets of drawings of all parts to be made, complete with some assembly layouts. First up is the drilling of the of the frames, which is best done with frames locked together so as to ensure that all bolt holes match. I did not know which method I would use. Clock makers use taper pins to fix front and back plates in a clock movement but I thought they might not be man enough. Eventually I clamped both frames together and drilled two holes diametrically opposite for 2ba screw/nut with a close fit clearance hole.  P1010056 P1010056 by Malcolm HARWOOD, on Flickr The observant will notice that I employed Record G clamps (cabinet making), which I subsequently changed to something a bit more sophisticated and also used a spotting drill. I had never used one before simply relying on my accuracy with a centre punch. I will however use it again as it ensures that the drill goes exactly where you want it to. I bit if a faff having to constantly change from spotting drill at twist drill but worth it. Why, I can hear you ask did I not do this on the mill with a DRO? Ah well, remember the "issues" talked about earlier? That is why I had to do it by the old method. I think that is enough to get started and I will post on progress again shortly. Cheers Malcolm |

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Apr 1, 2017 20:47:55 GMT

Hi Malcolm,

Very pleased to see your progress on your 5"g Don Young Hunslet of 'Quarry' type. It is a nice easy build. Everything is straight foward. The boiler is an excellent free steamer, and the balanced slide valves provide a very free exhaust.

Very pleased also to hear of your clockmaking - this is a subject that has always fascinated me.

Your gunmetal cylinders machining of on a Myford should be a piece of cake. Just make sure the steamchests are dead on size for the balanced slide valves.

When you look at the valve gear you willsee that the expansion link slot radius does not match that of Don Ashton's 'OJ' dimension ie eccentric rod length to sheave centre, plus you will note there is no offset on the suspension for the lifting links. These can easily be corrected when you get to this stage.

Good luck and happy building!

Cheers,

Julian

|

|