|

|

Post by andyhigham on Jan 27, 2021 6:27:29 GMT

David

Is that photo reversed? Reverser on wrong side

|

|

|

|

Post by jordanleeds on Jan 27, 2021 12:55:07 GMT

This thread is really helpful I'm about to send all the dxfs for my own Hunslet off to be laser cut and it's been a really informative and helpful thread to Use as reference

|

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Jan 27, 2021 13:04:03 GMT

Hi Jordan(?)

Glad to be of help.

Good luck with your build.

Cheers

Malcolm

|

|

dscott

Elder Statesman

Posts: 2,440

|

Post by dscott on Jan 27, 2021 23:24:09 GMT

David Is that photo reversed? Reverser on wrong side No that is planned as the GO FASTER LEVER!!!! No as I am doing 2 of them just a place to put it instead of a dusty drawer. These are modeled on the full size ones not the drawings. Again the correct place for them is outside with the Brake on the inside closer to the frames and the driver if needed. Again Don has done it wrong as per full size. Yes she identifies as a Port Class which has the frames down to the bottom at the ends. Plus the lovely drop for the cab. David and Lily. |

|

ngfan

Active Member

Posts: 20

|

Post by ngfan on Feb 8, 2021 20:28:02 GMT

Hello Malcolm, I continue to read your posts with great interest. I’m just about to start making the exhaust/blast pipe set up, and will follow your advice with respect to the use of jigs. I note from one of your photographs that you appear to have lifted the blast nozzle so that it is significantly closer to top of the smokebox. Is this on the basis of some advice you have been given - or am I just misinterpreting the photo? With regard to my more recent progress, and the slight changes I have made: (1) DY suggested attaching the 2 lubricators to the front buffer beam. Instead I mounted them on a ½” x 3/32” steel bar which I then bolted to the reinforcing angle on the bottom of the buffer beam. This means that I didn’t have to drill small holes in the thick steel buffer beam, and the lubricators can be removed quite easily. They are 2” x 1¼” lubricators from Polly Models, and just squeeze in between the buffer beam and the valve guides that stick out from the front of the valve chests. They are driven as DY recommends from the pump eccentric. I used ¼” x 1/16” steel strips as the connecting rods, and they had to be carefully bent to miss the brake and cylinder drain cock shafts and the pump stretcher. Perhaps it would have been a little easier I had followed DY and used a round rod with forked ends instead. Still I got away with it. ![]()   (2) I decided not to have the running boards stretching the whole length of the loco. Rather they stop before the cab, and the whole cab floor is made of a single piece of sheet steel. I felt that this would provide a stronger support for both the hand brake column, and the full height cab I intend making – I also had some suitable free 3/32” steel sheet hanging around. I have since realised that I’m probably going to have to provide an access in the floor to get at the boiler blow down valve. In making the floor I made the mistake of trying to silver solder on the reinforcing plate under the brake column. The whole floor distorted, presumably due to stress relief in the cold rolled steel plate. I started anew and just bolted the reinforcing plate on.   (3) For springing, I’ve used 5/8” steel spring that is used for binding heavy packing cases. It’s 26swg, and a crude calculation versus the 22 swg steel spring + tufnol strips that DY recommends seemed to suggest that 7 or 8 strips should be enough. In fact I don’t think it is, and when I get the boiler etc on I suspect it will sit too low. I’ll either need to lay my hands on some more of this banding spring, or fit different thicker springs. (4) Having made the reverser stand assembly some time ago, I‘ve now removed the drain lever quadrant altogether, replacing it with just the long drain cock lever with a handle on the end. I’ve used one of the holes left in the stand to hold a horizontal bar which keeps the long reversing rod off the cab floor. I don’t know why DY came up with the drain cock lever system – it wasn’t on any of the original quarry locos, and is more complex than the actual system! Cheers, John |

|

dscott

Elder Statesman

Posts: 2,440

|

Post by dscott on Feb 9, 2021 1:53:39 GMT

Yes Many of the bits Don did in his Design I feel were done as a chuckle. Lets make her as complex as possible. 2 The Brake is in fact close to the frames so that the bracket and length of the shaft can be shorter. 4 The drain Cocks thingy?  See above. Me the curved stretchers? Again see above, as in full size, planks of steel with angles riveted on were the order of the day as fitted to my second model. PHOTOS. Open up a new e.mail address. think up a name. Go for a new account. The same as everyone who has been banned off e bay does!!! IMGUR. Click on ADD IMAGES Click on box BROWSE Find Mug Shot from your file in the computer. Click on it. Click on OPEN box at the bottom. Go and make some tea while it uploads. Green line above. Click on GENERATE IMAGE LINKS box number 4 in the row. Go down to GENERATE IMAGE LINKS. Click on it. Click on your photo from the stack. it will have a green box. OOPS wrong one click on the tick. That's a better one it makes me look slimmer... Younger... Fitter....... Click on DONE. Like Mr BENN a Box will appear. Go down the Menu to BBCcode (message board & forums) Click on it. RIGHT CLICK within the box. COPY will appear. Left click on COPY. At the top. Come back to the forum!!! Open up REPLY. Click within the big box. Write something. Or RIGHT CLICK and a white box will appear. LEFT CLICK on PASTE. Done. Add amusing comment below. Click on CREATE POST Drink your tea trying not to laugh. Duck the Flack. David and Lily. |

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Feb 9, 2021 7:50:15 GMT

Hello John/ngfan

Thanks for your comments.

Julian kindly checked out the blast nozzle/petticoat layout for me. This is about what he suggested. Time will tell how well it draws/drawers/draughts/steams??.

The steam valve lubrication will be done via a hydrostatic regulating valve fed from a pressurised tank between the front frames/buffer beam. Description in my next posting. Hope it all works.

Running boards etc as per DY design om my engine.

My springs have 3 spring steel elements to DY spec/design. The remainder are Tufnol strips. I hope that they are stiff enough.

Drain cock levers as per DY design. Agree they and the linkage are fiddly. The actual valves, from Blackgates, seem better suited for a much smaller scale.

I find Flickr excellent for uploading pics. You get a 1000 limit for free.

Good luck

Malcolm

|

|

ngfan

Active Member

Posts: 20

|

Post by ngfan on Feb 10, 2021 9:52:23 GMT

Hello again Malcolm.

I used Polly's own design of drain cocks. Like all model drain cocks they are rather fiddly, but I have them on my Polly Caroline, and they look rather more robust than the Blackgates ones on my Simplex.

I did think that blast nozzle looked unusually low in DY's actual design. In fact I suspect that with such a tall chimney, a narrow gauge model loco provides an easier draughting challenge than with the short chimney on a typical standard gauge model.

I've been rather frightened by hydrostatic lubricators, perhaps because none of the locos in our club use one. I can see the arguments in their favour, particularly you can see when they are working.

I'll look into Flikr. I'm not a particularly enthusiastic or competent photographer, so I've never bothered about these sharing sites.

Keep up the good work.

Cheers,

John

|

|

ngfan

Active Member

Posts: 20

|

Post by ngfan on Feb 11, 2021 14:15:51 GMT

Somewhat to my surprise, I've successfully set up a Flikr account, and inserted the images into my original post of 8 February.

John

|

|

|

|

Post by jordanleeds on Feb 14, 2021 21:39:55 GMT

Just spent the evening drawing up dons boiler for the Hunslet with a view to sending out for the plates to be water jet cut and the flanging blocks to be cut this week inch thick plates

|

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on May 17, 2021 15:29:37 GMT

Good Afternoon

I am trying update progress of the Hunslet build.

However,try as hard as I can, I cannot seem to get the BB code via the upload/share button (downwards pointing arrow?) in the bottom right hand corner, prior to copying it over into my thread in ME Proboards.

I have used the "Roger method" successfully for the last 4 years without a hitch. That is upload all the photos via BB code and then add the text.

Has anybody else had this problem with Flickr?

There are one or two comments in the self help forum on Flickr regarding cookie choices in that Flickr want access to all your details to sell onto anybody who is interested. Bit invasive I think so I normally say no thanks.

Interested to hear others comments/experience.

Cheers

Malcolm

|

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,864

|

Post by uuu on May 17, 2021 16:50:28 GMT

I can get to the BBcode on your Flickr photos posted earlier in this thread, having said no to all the cookie choices they gave me. So fundamentally your account is OK. Are you on an Apple machine - I know John the Pump can't get Flickr to work on Apple, but it's OK on a PC.

Wilf

|

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on May 17, 2021 17:14:23 GMT

Hi Wilf

Yes I am on a Mac desktop. Flickr has run seamlessly up until today. I select the photo I want. Click the downwards arrow in the lower right hand corner and I get a box aski=ngwhat size I want and then get a box telling me I am opening up the jpeg picture.

No mention of the bb code.

Malcolm

|

|

uuu

Elder Statesman

your message here...

your message here...

Posts: 2,864

|

Post by uuu on May 17, 2021 17:31:11 GMT

If you do the text - I'll put the photos up. Here's one - looking good  fullsizeoutput_e5d fullsizeoutput_e5d by Malcolm HARWOOD, on Flickr Stick the text up with a place holder for the photos and I'll reply embedding them in the right place. Wilf |

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on May 18, 2021 13:52:21 GMT

Hi Wilf

Have sent you a PM

Malcolm

|

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on May 18, 2021 17:29:43 GMT

Evening all Here is the latest update

Hydrostatic oil lubricator. DY suggests that you make two mechanical ratchet type lubricator pumps and tanks, installed behind the front buffer beam. They looked quite complicated to me and I noted from "search" on the forum that the ratchets were not always long lived. I had read about a pressurised lubrication system using steam condensate to force steam oil out of a tank and into the valve block in a back issue of ME. I managed to obtain a single feed control valve with sight glass for SW Steam who assured me one was sufficient when used with a tee piece making sure that the feed pipes were exactly the same length to ensure even oil delivery. The photo shows the parts of the system. The tank is made for square section brass tube with let in silver soldered ends. It has an approximate capacity of 140cc. A supply union delivers condensate into the bottom of the tank at system pressure via a control valve from an additional tapping on the manifold. A weir type outlet takes oil forced up by the pressure of the condensate (oil floats on water) to the site glass where it can be regulated and on into the valve blocks. A water drain is situated in the middle of the tank, which is in fact now a cylinder drain cock valve (not shown). A more sophisticated operating lever is to be added shortly. I was concerned that the control valve/sight glass may be a bit vulnerable to knocks in the position I had chosen on the running board. I though I remembered seeing the Hunslets at Porthmadog with "little dustbins" for the sand boxes. It was pointed rapidly by other forum embers this would have been a Fairlie not a Hunslet. Silly me! I cut an observation window to check on the flow of oil going to the valves. The interior seemed very dark and a strip of Plasticard was installed to lighten the interior. A filler tube with a 3/4" hex plug and O ring complete the assembly. This clearing the foot plate in front of the smoke box.

This shows the unit partially assembled. The cylinder drain cock is from SteamFittings of Barmouth. This thankfully has a generously proportioned actuating lever with a 6BA threaded hole, not the clock makers 10BA hole from other suppliers. I sometimes wonder if our suppliers actually try using some of their products themselves in anger? They could not possibly be just chasing the lowest price from some wholesale supplier from the East (and I don’t mean Ipswich), could they?

As previously mentioned it is important if using a single sight glass lubricator and a tee piece to ensure that the two pipes downstream of the tee are of equal length. To guarantee this I made a simple soldering jig and used two pieces of pipe of exactly equal lengths.

This is the result after fitting. Fingers crossed that it will all work OK and pass a hydraulic test.

The engine from the front looks more or less finished. Although it is still mounted on the rotating stand. More on handling this extremely heavy engine (I guess 50+kgs) later on.

The completion of the piping up of the boiler backhead can now be completed

The backhead is now fitted with all its pipes and non-return valves. The emergency hand pump has been relocated into the space reserved for coal in the full size engine. The left hand clack valve has a dual feed of either direct from the front axle crank driven boiler feed pump or when the bypass valve is shut via the emergency hand pump from the auxiliary water tank in the riding car. I had to do this as the ashpan operating damper lever was fouling the pump bracket. The red line sight glass work really well. Note my take on asbestos rope lagging on the blower feed pipe. Where and how did I obtain that ? The newsagents. It's packing string!

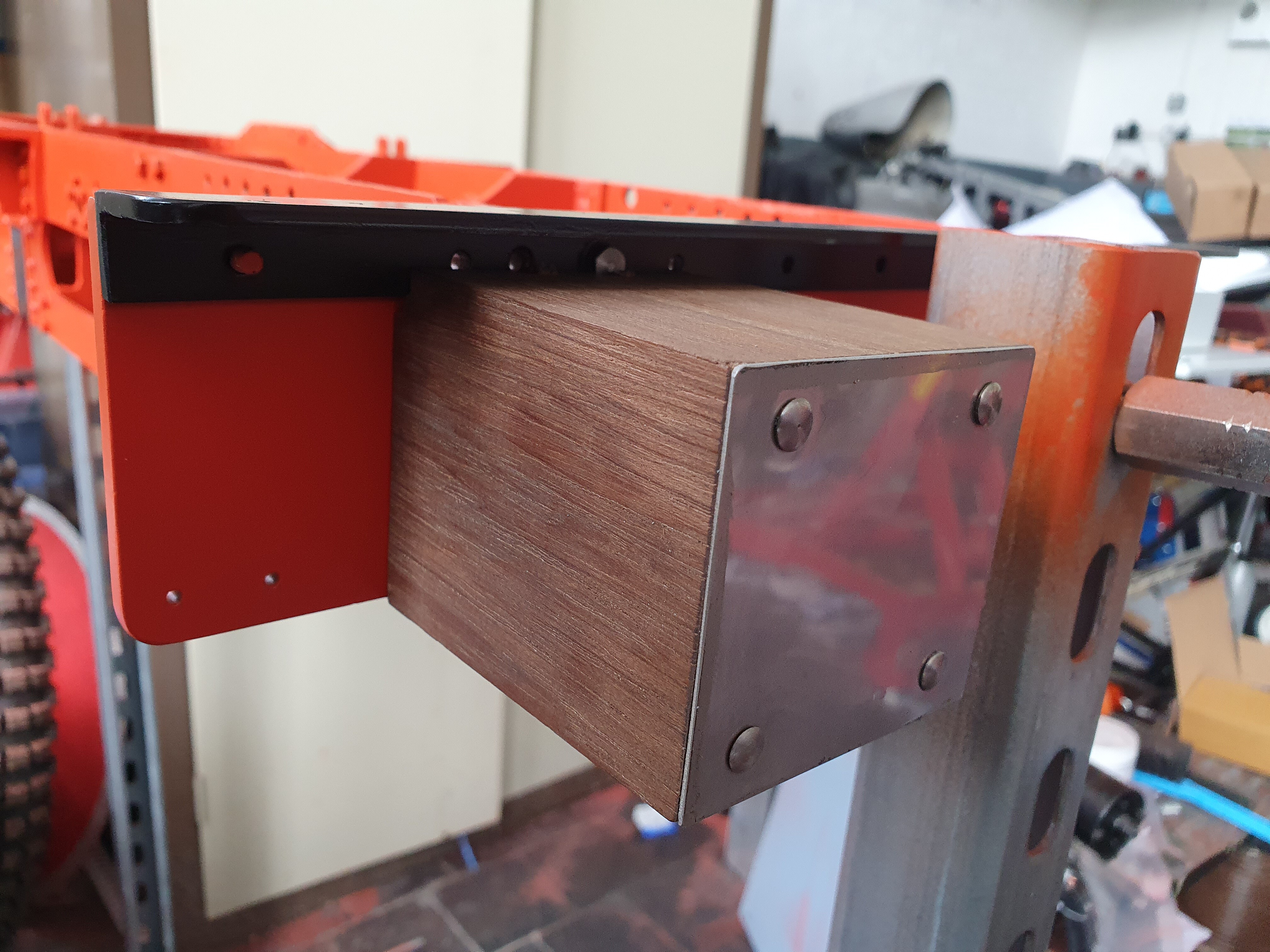

The time had come to take the engine of its stand. I just hoped I was not going to regret it and find that I needed to sort something that was best reached with the engine on its back, upside-down. The dumb buffers made from Sapele (I think) as per DY design had been lurking in the workshop for the last 4 years and at last I could fit them. I noted that on a visit to the Lake Bala Railway that the buffers has what looked like old boiler plate bolted to their faces. I did my best to replicate this with blued 10 thou' shim and 2mm self tappers. They are fixed to the buffer beams with 4mm dowel screws, which if ever you have self assembled IKEA furniture, you will know all about.

The right hand boiler feed clack is fed via a horizontal injector drawing water from the riding car tank and steam from the turret. Note the damper operating lever for the ash pan. Also an extended cylinder drain cock operating lever. The original can be seen but there is virtually no room for fat fingers because of the brake pedestal.

The brake column is installed and connected to its arm under the running board. I gave up trying to turn a hand beaten bead for the firebox trims. I think I need a bead roller (Jenny mill ?) but the purchase of specialty tools has to end somewhere.

The riding car is connected to the engine by a rigid coupling . The water is transferred by quick release couplings supplied by Polly Engineering. Dumb buffers awaitng fitting. Next post will report on a solution to handling a heavy engine and first low pressure hydraulic tests. Thanks for reading. We are almost there! Cheers Malcolm |

|

|

|

Post by andyhigham on May 18, 2021 18:04:11 GMT

My dumb buffers are made from Burmese teak. The actual wood was en route to UK from Rangoon on SS Pegu when it was sunk by a German Uboat in 1917. The timber was salvaged from the wreck in 2008, the buffers are part of this salvage. Since the photo was taken I have added a radius to the face  20200510_164114 20200510_164114 by Sigma Projects, on Flickr |

|

dscott

Elder Statesman

Posts: 2,440

|

Post by dscott on May 18, 2021 23:18:39 GMT

Wonderfully Pegu is Chinese for Bottom Poor Ship.

But you get well seasoned timber.

Yes I am continuing to enjoy these chapters as they arrive.

Our Hunslet will have to get its socks on ready for the Dreaming Spires this year.

Drop everything and do only one project.

David and Lily.

|

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on May 19, 2021 22:20:50 GMT

Hi Malcolm,

I'm not happy with the brass horizontal square tube as the displacement lubricator 'oil tank'.

The brass firebox door offends aesthetically my taste, and is not prototypical.

Cheers,

Julian

|

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,993

|

Post by JonL on May 21, 2021 18:41:43 GMT

Hi Malcolm, I'm not happy with the brass horizontal square tube as the displacement lubricator 'oil tank'. The brass firebox door offends aesthetically my taste, and is not prototypical. Cheers, Julian I don't think it matters a damn who is happy other than the builder and the boiler inspector. |

|