rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Sept 19, 2018 18:58:10 GMT

Don uses a big spring in the middle! Someone said that he had used 4 smaller, one in each corner in holes and had great success! This is what I have done. Easy to adjust!! David. David Have sent you a PM Malcolm

|

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Nov 28, 2018 19:12:49 GMT

Good evening to you all.

What! Is it really 11 weeks since I updated this thread. No wonder I had to search for it on page 4.

"Things". That has been the cause of the delay. A 17day road tour of New England in The fall with a bit of Manhattan at the beginning and end. Half term with grand children. A "kulture kram" for 3 days of many of the London art galleries.Suppliers who say they have things in stock and haven't (they buy them in when they get an order) and those that say "ask questions" but never ever get back to you ( I could make a list). And on and on.

Anyhow. Let's stop moaning and bring you sort of up to date with the Hunslet build.

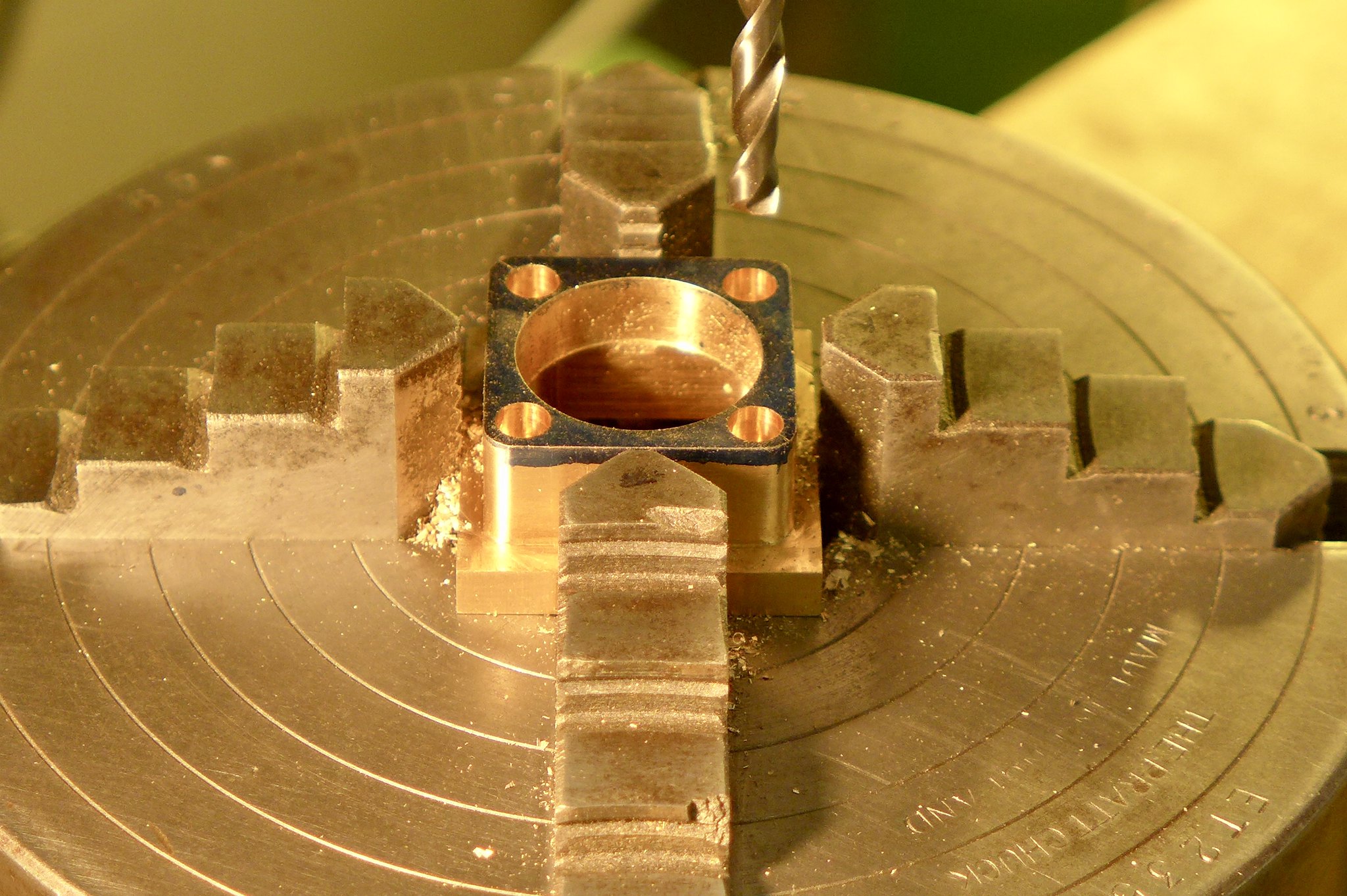

You will recall I had some doubts about Don Young's tiny spring not being able to knock the skin of a rice pudding on the floating valve piston. Dave Scott told me about a mod with what I would call "pocketed springs". With the help of Lee Springs I chose four likely looking compression springs and taking courage in both hands starting machining the valve shown in this photo

fullsizeoutput_8dd by Malcolm HARWOOD, on Flickr fullsizeoutput_8dd by Malcolm HARWOOD, on Flickr

The result is just about right with the combined spring force overcoming the O ring "stiction" and causing the balance piston face to lightly touch the outer face of the valve body.

I then seem to have spent a lot of time trying to sort out copper pipe and pipe fittings. You more experienced guys will laugh at the hours I spent trying to sort this out, I imagine that you will have a biscuit tin of assorted pipe and fittings of many types and sizes. Well. I haven't! I think though I am slowly getting there.

I am getting close to being able to assemble the complete motion on each side and there are many little jobs to be done such as gland followers and studs. Here I am putting the taper pin in the cross head. The piston is firmly attached to the piston rod and I think I have used Loctite, some time back, to make sure it does not turn, so I am across drilling the rod in this heavy duty arrangement as I do not want the piston to be dancing around whilst I was working at the other end. I used a taper pin reamer incidentally.

You will see from the above photo that I have had to resort to packing pieces in order to get the slide bars aligned. They have been a bit of a bugger. There are so many mounting points that are just clearance holes plus the fact that one of the gland castings started off more of less to size with the added challenge of a taper. Maybe I should have sent ot back to Reeves and asked for a new one.. The other one was fine with plenty of machining allowance.

I have finished today assembling the cylinders with all stainless studs washers and nuts. The Clupert piston rings fit OK and they appear to have the correct gap when offered up to the cylinder bore. i await a small piston ring compressor before putting them in the bore. I appreciate that many builders say cast iron rings in gunmetal bores are not a good idea. I have scoured past threads on this topic and there are at least three builders who swear by this combination and have not suffered wear problems.

Here is one of the cylinders awaiting its piston. Yes. The nuts have yet to be tightened up!

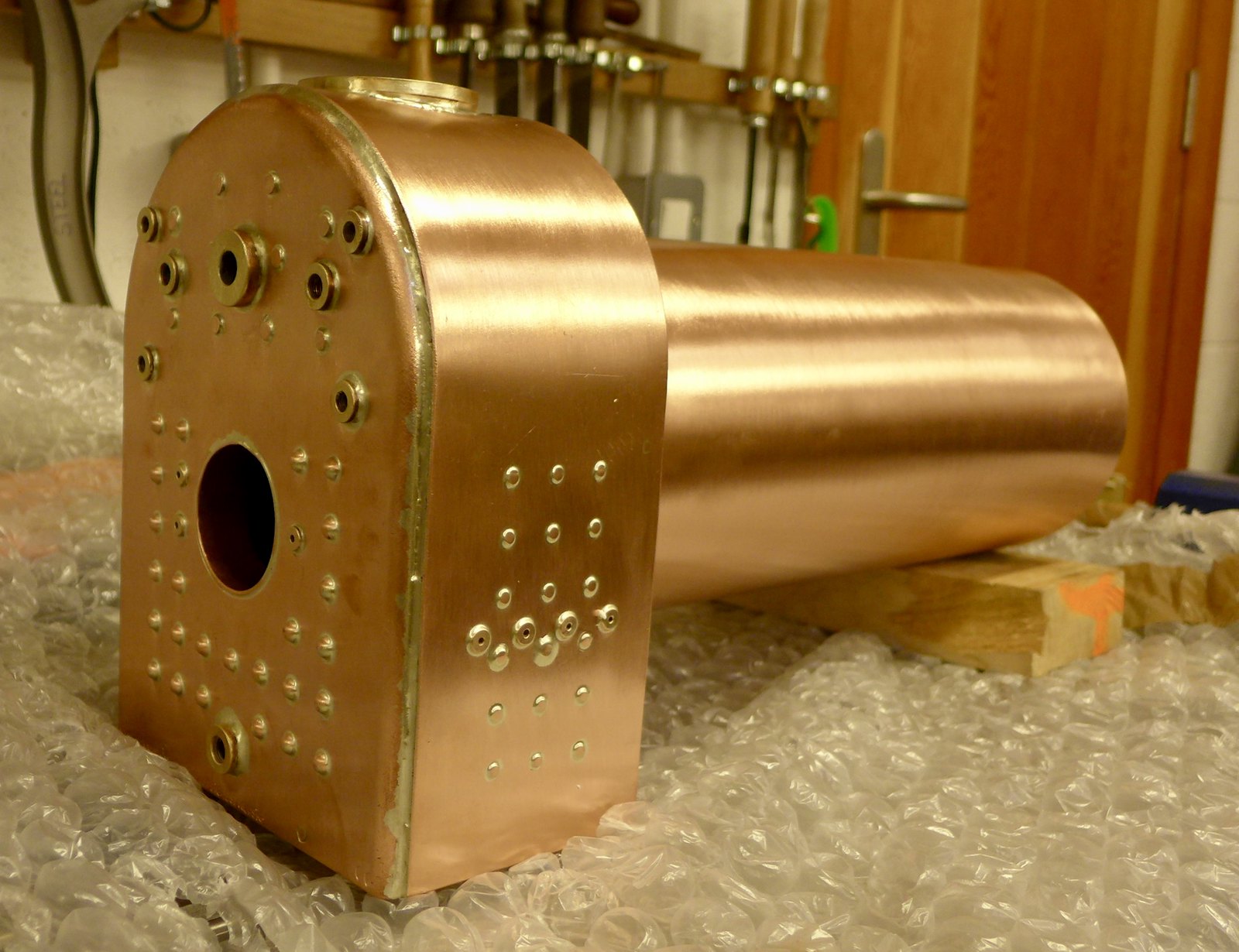

Just to add pressure and to motivate me that I will see this engine running (one day) look what turned up the other day. Lovely job don't you think. Well done to Helen and crew at Western Steam.

fullsizeoutput_8e0 by Malcolm HARWOOD, on Flickr fullsizeoutput_8e0 by Malcolm HARWOOD, on Flickr

Best get on then!

Thanks for reading and I hope some of you find this interesting.

Cheers

Malcolm

|

|

|

|

Post by Roger on Nov 28, 2018 20:39:09 GMT

Hi Malcolm,

I do like the Piston and Rod setup, you can't beat a satisfying setup! Cracking boiler too.

|

|

|

|

Post by ettingtonliam on Nov 28, 2018 20:55:35 GMT

The boiler looks first rate! Just a little point, could you up the size of the font next time, oldies like me whose eyesight isn't what it was find such tiny print difficult. It need not be big like you sometimes use, just normal size (I didn't even know you could change it!)

|

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Nov 28, 2018 21:33:33 GMT

Hi Malcolm,

Yes the small odd font also caused me problems, same as Richard!

Having the boiler for Xmas, and by Helen as well, is a huge step forward! I can vouch for the excellent steaming capabilities of Don Young's design for the boiler.

Personally, I would have thought that with your professional experience with glands and O rings etc would have told you that cast iron rings (even of cluplet design) are going to wear the gunmetal bores of the cylinders even with generous steam oil supplied. The cast iron forms a glass like hard surface in use whereas in its ordinary state it is very 'soft' and easy to file and turn if not chilled.

I might be proved totally wrong, but cast iron rings in gunmetal bores is a complete 'No No' in my book. If graphite asbestos square packing is used you might have to replace the packing after 10 years, but the bores will be OK. In your case, I would suggest after a few years of serious hard work your loco will require a rebore on the cylinders, plus as a result new pistons, and whatever you then decide to seal the pistons with.

You also now introduce all the problems associated with oiling after a steam up to prevent rusting of the cluplet rings.

Cheers,

Julian

|

|

mbrown

Elder Statesman

Posts: 1,796

|

Post by mbrown on Nov 28, 2018 21:59:58 GMT

Regarding packing pieces to align the slidebars, full size practice is always to use them so that adjustments can be made when slidebars wear or are replaced or otherwise need realigning. So your approach is actually more prototypical!

Love that boiler - how does she keep the silver solder in just the right places and nowhere else?.... beautifully neat.

Malcolm

|

|

|

|

Post by Deleted on Nov 28, 2018 22:00:33 GMT

Hi Malcolm I would agree with Julian re cast iron rings in gunmetal bores, whether talking steam engine or IC petrol engine, the rings ideally need to be a softer material than the bores so that they endure all wear and not the bores. I take note that you found 3 ME's who say it works but I can't get around my head how that is possible? Bronze would be better if wanting a metal although personally I'd be looking for a bronze that's softer than the bore, brass has been used too. The other option if not wanting the traditional graphite packing is a plastic, such as PTFE. there are different grades/types, something which is graphite loaded being the best solution from what I've read. I should be at this stage soon myself and will need to make a decision as to what I plan to use, I had considered an 'O' ring but have nearly (95%) decided against this now. So it will be either graphite PTFE or bronze. You may find this article/method of making PTFE rings of interest. modelengineeringwebsite.com/Steam_piston_rings.htmlregards Pete NB:.. btw.. love the boiler..  |

|

stevep

Elder Statesman

Posts: 1,073

|

Post by stevep on Nov 29, 2018 10:33:26 GMT

Malcolm,

You said that the springs just overcome the 'stiction' of the O rings. Don't forget that, when under steam, the steam will force the upper part upwards and the main slide valve downwards.

On LBSC's PANSY design, the valves are under the cylinders, and can fall down when there is no steam. But when the steam is admitted, the valves get pushed up against the port face.

|

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Dec 1, 2018 19:57:30 GMT

Evening all

Thank you for all the comments to my recent post and the "likes". Motivates me to remove my finger and get on with this "simple" engine.

Roger: Funny, I was thinking of you as I was heaving that huge cubic face plate thingy onto the mill bed. I have two of them. A gift from my chum who gave me his Harrison lathe. I though at the time I will never ever use them by I did not like to refuse them. They are useful and very accurate (square). I have used them a lot.

Ettingtonliam. Apologies for the font face disaster.

I had changed both the font face and size. Initially it was too large and seemed to effect everything including Concorde and the photos which is why they look super large.

I then tried to change the font size back down again, but it had no effect (at my end). Obviously it did at yours.

The font size had gone back to very small about 4 hours late with me. All very strange.

I do not like the default font face. I prefer Arial and in 12 point, a bit bigger, with lots of paragraphs.

Others might like to note that, as I find some posts very "dense")

I get a string of icon options at the top of the page. A bit like that in "Word". Maybe this only works when starting a new post, not a "quick reply". Can anybody advise, please?

Julian: I have sent you a PM.

mbrown: Thanks for the comments re packing pieces on full size loco' slide bars, That makes me feel better,

Incidentally, the Western Steam boiler is TIG welded.

greenglade: Thanks for your views on this topic. I have dug out posts of excellent CI ring/gunmetal bore service from "61962" and "ettingtonliam", to name but two. I have found others as well.

However I have decided to fit graphite filled ptfe piston ring seals as per the mentioned article. This is standard in hydraulic practice,although as different as chalk and cheese.

steve p: Thank you for this info. I thought as much. My spring force is still very low and I have only about .020" compression when the valve chest cover is in place. I guess with full boiler pressure the load will be considerably more even though they are termed as "balanced piston valves"

So much still to learn!

Busy with completing pistons and valves, setting valves and running on air.

Will take some photo's. Watch this space.

Thanks for reading

Malcolm

|

|

|

|

Post by Jim Scott on Dec 1, 2018 21:16:45 GMT

Hi Malcolm

I'm enjoying your description of your endeavours (I don't know where folk get the time to do this). I especially commend you on the quality of your photographs which are invariably well lit and correctly focussed. Note to self: must do better.

Talking of CI rings in a gunmetal bores, I can confirm that 61962 (Eddy) once told me that he had used this combination in the dim and distant past without a disaster occurring..? Having said that, I'm no fan of this combination either, for all the reasons already stated.

That looks like an excellent boiler from Western Steam, but I have to correct your statement that it is TIG welded. Nothing wrong with TIG-welding copper but it looks like a superb example of silver-soldering to me..!

Jim S

|

|

|

|

Post by ettingtonliam on Dec 1, 2018 22:29:38 GMT

Malcolm

I'm curious because you credit me with a posting commenting favourably on a cast iron ring/gunmetal cylinder combination. Can you remind me what I said, as my normal reaction is 'don't do it' Maybe I'm at the stage in life where I can't remember what I said any more!

|

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Dec 2, 2018 7:53:46 GMT

Hi Malcolm I'm enjoying your description of your endeavours (I don't know where folk get the time to do this). I especially commend you on the quality of your photographs which are invariably well lit and correctly focussed. Note to self: must do better. Talking of CI rings in a gunmetal bores, I can confirm that 61962 (Eddy) once told me that he had used this combination in the dim and distant past without a disaster occurring..? Having said that, I'm no fan of this combination either, for all the reasons already stated. That looks like an excellent boiler from Western Steam, but I have to correct your statement that it is TIG welded. Nothing wrong with TIG-welding copper but it looks like a superb example of silver-soldering to me..! Jim S Hello Jim

Where are you in NE England.? I am often up and down the A1M from Thirsk. Maybe a meet up one day?

Point taken re piston rings.

Have reread (very closely) the QA Documents that have come with the Western Steam boiler.

You are correct. It mentions both silver solder and the TIG process in the Permanent Jointing Materials and Permanent Joints sections.

It's just that the word TIG caught my eye. I did not expect to see it. I wonder which bit is TIG welded?

You are right re the amount of time to write the build up as the photos are taken over say an 8 week cycle and matching up the commentry with pictures always take several hours of quiet concetration.

Cheers

Malcolm

PS Panasonic Lumix digital compact camera. Very fast Leica lens. Heavy tripod. 2 second delay before the shutter opens.

|

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Dec 2, 2018 8:06:42 GMT

Malcolm I'm curious because you credit me with a posting commenting favourably on a cast iron ring/gunmetal cylinder combination. Can you remind me what I said, as my normal reaction is 'don't do it' Maybe I'm at the stage in life where I can't remember what I said any more! Good Morning ( I think it's Richard isn't it?)

I did this research several days ago and wrote all the names of pro CI piston ring users in gunmetal cylinders down on the "scrap or paper". Of course, when I came to write up last nights notes the paper had gone missing and I cannot find the quote from you.

Apologies it may have been some other august member

Just one of those senior moments, which I insist I never have!

all the best

Malcolm

Found it! You were right it was not you, but "pault"

See below.

Project 2 , LBSC Heilan Lassie

Jun 8, 2013 at 7:50pm

Quote

like

Post Options

Post by pault on Jun 8, 2013 at 7:50pm

Hi Pete

Just to muddy the waters a bit I have used cast iron rings in bronze cylinders without any problems relating to ware. When you look at the piston speeds our locos run, the relatively few miles they run, low cylinder pressures and the fact that they generally are over lubricated, as long as you are sensible with wall pressure there is no problem. My personal preference is for clupet rings all round.

However I intend to put PTFE rings into the current project because the cylinders are brass, and I don’t want to risk scoring the bores. Its 100 years old and not mine so I’m playing safe.

I have not made my mind up exactly how I’m going to do it yet, but was thinking about using an O ring under the PTFE ring, as a lot of hydraulic seals are done. The O ring acts like a kind of spring. If you use built up pistons you can have rings with no gap at all.

I will be interested in what you decide.

Regards

Paul

|

|

|

|

Post by ettingtonliam on Dec 2, 2018 20:20:59 GMT

Thats a relief then! I've used cast iron pistons with rings or O rings in cast iron cylinders, gunmetal pistons in cast iron cylinders and gunmetal pistons with soft packing in gunmetal cylinders but never cast iron pistons with either O rings or piston rings in a gunmetal cylinders, and frankly I'd be wary of trying it, whatever others have said.

|

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Apr 7, 2019 19:43:56 GMT

Good Evening to you all of you who have been following the build of this "simple" engine. It has been some time since I last posted and I find my diary lost in the depths of page 7. This means that if I am to challenge Rogers record I will be 150 years old by the time I get to 500 pages! Progress on the build has been exceedingly slow. Even with an honest 4-5 hours every day 5-6 days per week it seems as if I will never finish. My original aim was to have the motion running on air after 12 months but it has turned out to be 24 months (see later). In my last spate of messages I had lots of advice about the best way to seal the piston. Don Young (DY) recommended cast iron rings on a cast iron piston running in gunmetal bores. After much toing and froing and the fact that even with a piston ring compressor I could not get the mounted cast iron cluppert ring to fit my cylinder bore ( I was frightened I would snap the ring and score the bore) I gave up. The solution was to machine up a new piston head, from bronze, and fit a 6mm square section graphited braided packing seal. Please do not report this heresy to the European Society of Hydraulic Seal Engineers as I will be blackballed and struck of their Christmas Card list. However it does seem to work. At least on air. So, what do I know? Sorry, no pictures. On to the pictures. First up is me deciding that the valve spindle guide needed fixing permanently to the side frames. here I am drilling clearance holds after spotting through form the frames.  fullsizeoutput_8f3 fullsizeoutput_8f3 by Malcolm HARWOOD, on Flickr

The valve chests have a steam inlet port, through which i wanted to feed compressed air. Dear old DY called up a 5/8" x 26tpi British Cycle thread for this. Not an everyday thread and the tap and die unlikely to be in your toolbox. Coupled to this was the advice to use "commercially available" fittings which are normally BSP so an adaptor was made with a plain diameter which would enable it to be silver soldered to a commercial copper compression elbow.

This is how it looked like prior to soldering, awaiting its connector pieces of standard 15mm copper pipe.

fullsizeoutput_8f6 fullsizeoutput_8f6 by Malcolm HARWOOD, on Flickr This is how it looked like in the end with a standard air line connector

fullsizeoutput_9c1 fullsizeoutput_9c1 by Malcolm HARWOOD, on Flickr

After getting the air/steam into the valve chest and cylinder we now have to remove it through DY's graceful bifurcated "Y"piece. Again he suggests using standard couplings but I could find none with such a large radius. A plumbers pipe bender was brought into action and two 90° bends made. The top is tied together with a sleeve that will be eventually used to locate the blast nozzle. I would recommend the use of a soldering jig such as shown as doing it freehand, believe me, will not end in success.

fullsizeoutput_9b4 fullsizeoutput_9b4 by Malcolm HARWOOD, on Flickr The joint for such a "Y" piece is made by carefully milling the two bends so that you end up with half a diameter thickness, if you see what I mean? A fixture such as shown helps to keep the tube from moving whilst being milled with 10 thou' cuts at each pass.

fullsizeoutput_9ad fullsizeoutput_9ad by Malcolm HARWOOD, on Flickr I "tinned" the joint faces prior to mounting it in the collar and went for it. It was necessary to tidy the joint up with a bit more solder. However I only had to make one.

fullsizeoutput_9b5 fullsizeoutput_9b5 by Malcolm HARWOOD, on Flickr

At this point I expected to have the assembled parts running on air.Unfortunately this was not so. The whole lot was STIFF and I mean Stiff. It could not be turned by hand plus the fact I had concern about the coupling rods adding to the problem. I began the start of a number of strip downs and easing of parts. I was worried that the DY method of quartering with a scribed line and a vertical engineers square could lead to inaccuracies and non uniformity of the 90° quartering angle. Thus I made a quartering jig and set the vertical accurately and the opposing crank height with slip gauges so that I knew that the angle would be consistent for both axles.

I had problems getting equal events in the valve gear. Stephenson's balanced valve gear does not allow you to easily see the position of the valve body in relation to the ports as they are hidden by the balance valve piston head and valve buckle, so I made a scale model of the valve and ports and with the aid of the slip gauges made sure that the valve was dead central in mid gear. (The valve has been displaced in the below photo for sake of clarity)

fullsizeoutput_9c3 fullsizeoutput_9c3 by Malcolm HARWOOD, on Flickr I still was not getting equal valve movement until I read in a book that it was good practice to make sure that the eccentric rod for forwards motion should lie next to the frame, on both sides.

Surely I thought I have changed these over lots of times, but I did it one more time and took measurements again. This time I achieved minimum movement on both sides at mid gear and maximum ( and equal) movements at full forward gear and full backward gear. I was encouraged and connected everything up and after 8weeks of messing about trying to get the engine running smoothly on air it worked.

I have posted a separate short video of it next.

Thanks for reading. i hope you found something of interest in there?

Cheers

Malcolm

|

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Apr 7, 2019 19:53:35 GMT

Here is the video of the first run of the mechanical parts, as mentioned above. Still a bit stiff but I think we are getting there. BEWARE TURN THE SOUND OFF AS THE COMPRESSOR CUTS IN AND IS VERY NOISY.  Hunslet on ai Hunslet on ai by Malcolm HARWOOD, on Flickr |

|

|

|

Post by terrier060 on Apr 8, 2019 11:21:03 GMT

Excellent Malcolm - so nice to see a running chassis. Could you film from the other end with the mike nearer the exhaust and further from the compressor?

Love the boiler - Helen made a great job of soldering my Terrier boilers

Ed

|

|

|

|

Post by Roger on Apr 8, 2019 12:08:00 GMT

Great progress, and beautiful workmanship as always. I love the wooden fixture for machining the flat on the blast pipe 'Y' section, an excellent solution.

It's an absolute joy to get it all in motion, it's a significant step forward.

|

|

rrmrd66

Part of the e-furniture

Posts: 339

|

Post by rrmrd66 on Apr 8, 2019 16:55:52 GMT

Thanks Ed and Roger.

The approval of luminaries, such as you two, does wonders for the motivation.

Regards

Malcolm

PS Ed. Will try to do another short video from the other end.

|

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,993

|

Post by JonL on Apr 8, 2019 20:32:54 GMT

Fantastic work! I'm about to start the blast pipe myself, so seeing how you've done it is really helpful.

|

|