barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Apr 19, 2018 14:55:24 GMT

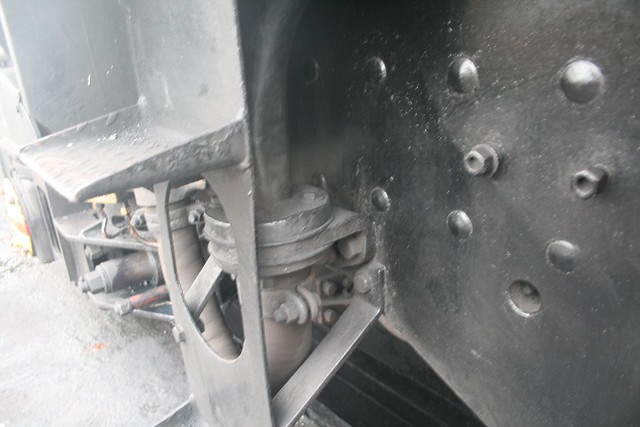

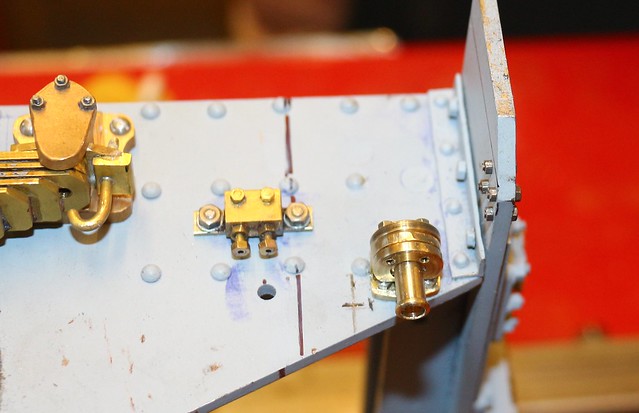

Hi Everybody Just a quick update from Barlow Works. Here are the guard irons fastened to the other side of the step bracket. That completes the rear steps. I can't do the front ones until I make the platforms on the front as the front steps are attached to the upper platform.  IMG_2209 IMG_2209 by Michael Cawthorne, on Flickr This is the water connection to the filter and its bracket from Britannia. The one on Oliver Cromwell is bolted to the drag beam for some reason, this one being bolted on to the frames. Not knowing what was on Flying Dutchman I opted for the frame mounted one as being easier. Its hard to see anyway being behind the front steps.  img_6353 img_6353 by Michael Cawthorne, on Flickr This is my attempt, being bolted to the frames with 10ba bolts. The main part has a flange that is then bolted into a retaining collar below the bracket through clearance holes. This is also counter bored ready for the fitting of the water pipe when the filters are ready to be fitted. The hose for the injector water feed goes on the bottom. I think that this may be the first part of the chassis that I have made that will actually have a function on the completed engine.   water bracket crop water bracket crop by Michael Cawthorne, on Flickr Next on the list will be the various platforms at the front and the brackets for the water pick up and brake gear. It's now starting to get serious.  Mike |

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Jun 4, 2018 20:04:01 GMT

Hi everybody

Its been quite some time since the last update from Barlow Works but is hasn't all been gardening leave, I have been slowly working on the Britannia tender chassis when time permits. Work this time has concentrated on the platforms at the front of the tender. These are intended to form the foundation for the brake gear cranks and the water pick up cranks and for a platform that fits on the top of the tender frame to which the steps are mounted. Again quite a bit of this had been made by the previous builders and followed the Perrier drawings. Corrections and improvements have been made where I was able and the following gives a guide of what I have done. Firstly (though a little out of order) is the platform above the tender frames. This was just a sheet of brass with an upturn section on the front. This photo from Oliver Cromwell shows its a little more detailed than that with bolt detail and also what appears to be a repair to the area round the drawbar pin hole. I quite liked the look of that and thought I would include it. Also, notice how the front buffer beam goes up to the platform edge without a gap, More on that later.  .

This is the platform complete with bolt detail (cribbed from Bob's (92220) thread where it appeared at just the right time) and the angle plate to the front of the tender which is also bolted on, not riveted as on the drawing. The countersunk screws were a bit of a dogs breakfast, already being drilled in the platform. Hopefully I can fill these when the platform is finally fitted permanently.

The angle plate also has triangular end pieces that are bolted on. Just a couple of pieces of nickel silver soldered in place with bolts to hold it in place.

This is the view from the rear showing the upper and lower platforms and their fixings.

This is the bottom platform with the brackets for the brake shaft and the bracket for the water pick up shaft. The brackets caused a bit of head scratching as it seems to be beyond me to bend a piece of metal to the correct size. I eventually invested in a couple of 90 degree V cutters from China and milled a V across the bracket with plenty of material to spare. They were then bent up and milled down to the correct dimensions. This might be the way everyone does it, I don't know, but it certainly worked o.k. for me. Finally the angle was reinforced with a fillet of 0.5mm silver solder. Remember, I am in Yorkshire and wear my belt and braces with pride.  The bearings were turned up and soldered in, the shafts, having been made by the previous builder were a perfect fit.

Here is the platform fitted with the drawbar pin. You will notice the strip of brass running along the top of the buffer beam. This is attached to the bottom of the platform and is to bring the buffer beam up to the bottom of the platform as it should be. Hopefully, as it is exactly the same size as the buffer beam it will not be too noticeable when it is painted black. Thanks must go to Bob (92220) who helped me solve this little conundrum. The buffer beam as drawn by Perrier is level with the top of the frames and this is how it was made by the previous builder. This leaves a gap between the buffer beam and the platform which is correct for a BR1G tender like on Evening Star but wrong for a BR1 tender like the one fitted to my engine, 70018 Flying Dutchman. I did not want to completely strip down the frames and make another buffer beam so hopefully this solves the problem without being noticeable.

Finally, the front steps are attached to this upper platform with 4 bolts. Those of you that have been reading the Micro Tig Welding thread will know that I bought a micro pulse tig welder. This is how I intended to use it, to temporarily hold things in place prior to silver soldering without having to clamp things together. This was moderately successful, the steps being held in place and welded whilst held in my fingers. As can be seen the welds are a bit smokey as I still haven't managed to get the argon feed sorted yet but I am quite pleased with the way its gone so far, obviously I need a lot more practice and to get the argon working but I feel that for me it has potential. The step plates, by the way, were made using my new found V bit cutter method and it worked a treat.

The steps have since been silver soldered without any mishap and are awaiting the dimpled tread fitting like I described earlier. I also need to have a look at the platform which also had a dimpled area directly above the steps. Also the steps will have 2 bolts fixing the bracing strips at the bottom like the prototype, not one like on the Perrier drawing.

Mike

|

|

|

|

Post by Jim Scott on Jun 4, 2018 21:32:57 GMT

Hi Mike Excellent work here. Just to confirm, your tack welded front steps are nickel-silver as per the rear ones you made and fitted previously? This looks as though pulse welding could save a fair bit of time and effort by dispensing with clamps etc. Have you tried to tack weld brass? Normally the zinc content makes conventional welding difficult but a pulse weld may hold together well enough to permit silver soldering. Try in a ventilated area, zinc fumes are not pleasant. Experimenting with a very small amount of compatible filler wire might improve things a bit. I'll be interested to hear of your continued progress and to whether argon shielding makes much difference.

Jim S |

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Jun 4, 2018 22:04:08 GMT

Hi Jim

The rear steps were nickel silver as I had a bit left over from my O gauge modelling. The front steps however are brass and the pulse weld applied in a couple of places is enough to hold things together long enough to silver solder. I'm sure the argon shielding will help a lot, I just haven't got round to getting it set up yet. I'm sure it will come into its own when I try the same methods with steel.

Mike

|

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Jun 26, 2018 15:15:40 GMT

Hi Everybody

Just a quick update to bring you up to date. In the last entry I had silver soldered the front steps together. Here they are with the anti slip finish done the same as the on rear steps. The only difference is that the pattern is bigger as the steps are wider. The steps are held on with 4 bolts onto the bottom of the upper platform and there are 2 stays at the bottom to hold it in place. The drawing shows 1 but that means the water connection would not fit and the real tender has 2 so that was good enough for me.

The top platform also has an anti slip surface. I did this by milling out a rebate in the top and made an insert with the detail on it from 12 thou nickel silver sheet which was soldered in place. The gap round the edge was filled with knife stopper and sanded smooth. It looks a bit noticeable as it is gray but is quite smooth. I won't know if its worked until I spray it black and have a look at it. I couldn't rivet through the upper platform itself as my riveter won't rivet through 1.2mm brass.

The upper parts are now complete and ready for the tank which the previous builder had made a start on, saving me a lot of time. The chassis is also now sat on its wheels ready to be shown at our up and coming Gala on the 6th and 7th of July. Also the next parts to be made will be for the brake operating gear. This will be my first time showing anything in public so I'm a bit nervous.

If you are in the area do come and see us, Its members and guests on the Saturday and open to the public on Sunday. If you are coming on Saturday just mention my name, Mike Cawthorne and someone will sign you in as a guest. I'll be the big hairy guy on the O gauge modelling table, not the small hairy guy with the little dog, though he is also called Mike just to confuse matters.

Mike

|

|

|

|

Post by Jim on Jun 26, 2018 18:16:16 GMT

Lovely attention to detail Mike. Brilliant work.

Jim

|

|

don9f

Statesman

Les Warnett 9F, Martin Evans “Jinty”, a part built “Austin 7” and now a part built Springbok B1.

Les Warnett 9F, Martin Evans “Jinty”, a part built “Austin 7” and now a part built Springbok B1.

Posts: 961

|

Post by don9f on Jun 26, 2018 21:01:45 GMT

I’ll second that! Now you’ve told us, I might just have a ride up one of the days.

Cheers Don

|

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Aug 25, 2018 16:10:57 GMT

Hi Everybody.

There hasn't been an update from Barlow Works for quite some time so this should bring everything up to date. I have been beavering away trying to complete the tender chassis. Parts of the brake gear and water pick up linkage were needed to be completed to finish of the chassis. As usual, quite a few of the parts had already been made by the previous builders to a very good standard. Odd bits and pieces were needed though to complete everything. This is an overall shot of the underneath of the chassis showing the brake and water pick up gear.

Here are some of the parts made by me, these are the brake leavers and the brake pull rod actuator plus the pins attached to the existing pull rod adjusters. Another exercise in my favorite pass time, silver soldering.  . The pull rod bearing with the two levers is probably the hardest thing I have made so far and I'm quite pleased how it came out.

This is the actuating lever to the water pick up apparatus. I also made up a collar to stop the shaft from sliding up and down, not on the drawing but it seemed like common sense to me.

This is the end of the water pick up gear that will eventually be attached to the scoop.

And from the other side. When the tender is completed the water pick up gear will be pinned up for safety but it is nice that it is all there and could work.

Finally, the last thing to be made was the drawbar.

As far as I can tell that is the chassis complete (but you can bet your life I've forgot something). I think the next thing for the chassis will be to strip it all down and give it a couple of coats of paint but for the time being I think I will put it to one side for a while. I really must finish that O gauge A4 for my mate Mike, he's already been waiting for it for 3 years, so after a tidy up that will be the next thing on my workbench.

All the best Mike

|

|

|

|

Post by Deleted on Aug 25, 2018 16:23:17 GMT

Lovely work Mike, I don't know why you worry about 'silver soldering'?..that 'pull-rod bearing' is a piece of art sir.....good to hear you're doing some O gauge models too...I have a few as does Jim...i did start the Hatchette A4 some time ago thinking I could just build it in the evenings as the issues were released, me being me I kept adding detail which was taking up far too much time. It's on the 'back burner' for now sitting in the glass case that I bought for it. I also have the brilliant 'Martin Finney' Gresley A1 kit with corridor tender to make a start on one day, I won't start that until the big one is finished...  Keep up the great work sir, your tender looks superb... Pete |

|

don9f

Statesman

Les Warnett 9F, Martin Evans “Jinty”, a part built “Austin 7” and now a part built Springbok B1.

Les Warnett 9F, Martin Evans “Jinty”, a part built “Austin 7” and now a part built Springbok B1.

Posts: 961

|

Post by don9f on Aug 25, 2018 21:33:44 GMT

Hi Mike....excellent job! I take it you’re not fitting a tender steam brake cylinder? I fitted one on my tender but it was a pointless exercise really and it’s never even been piped up!

Cheers Don

|

|

|

|

Post by Jim on Aug 25, 2018 22:04:02 GMT

As Pete and Don have said, you're doing a superb job there Mike in creating a true miniature of the real thing. I love it.

Jim

|

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Aug 25, 2018 23:04:01 GMT

Thanks for the kind words everybody. In answer to Don, it has always been my mantra that if it can be seen in a good photograph of the prototype then it should go on the model. Conversely, if it can't be seen I see no point in including it. I think the steam brake cylinder may fall into that category as does the vacuum piping. I included the water pick up gear as it can be seen through the cutouts in the tender frames. Mind you, I will check on the GA just to be sure. 😉

Mike

|

|

don9f

Statesman

Les Warnett 9F, Martin Evans “Jinty”, a part built “Austin 7” and now a part built Springbok B1.

Les Warnett 9F, Martin Evans “Jinty”, a part built “Austin 7” and now a part built Springbok B1.

Posts: 961

|

Post by don9f on Aug 26, 2018 15:30:26 GMT

Hi again....no I don’t think you could see the brake cylinder easily without the tender being over a pit! It’s link to the brake shaft, plus the pull-off spring are also well hidden.

I used to use the steam brake on my 9 when running on ground level track, as I was sitting on the tender and could often be running light engine. On raised tracks there is probably no need for working steam brakes on the loco at all, although I intend to keep the ones on my engine working, but not the tender....if I ever get it finished that is!

Look forward to more progress!

Cheers Don

|

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Jan 17, 2019 12:16:32 GMT

Hi Everybody

I know it has been some time since I updated this thread but I have been busy, honest. As I have stated previously, I have been building a DJH A4 in O gauge for a colleague and this is finally nearing completion. All the building is now more or less complete and it is awaiting painting when it gets a bit warmer. Here we have the main body, mostly a pewter casting that is very heavy. he should have no worries pulling a good load with this.

Details are either in the form of nickel/silver etches or lost wax brass castings. The rivet detail is done by drilling 100's of 0.5 holes and glueing 0.5 wire in place then cutting and filing to length. The cab is a nickel/silver origami exercise. but goes together beautifully.

This is the back head finally finished. It is a one piece slide in unit, the seats and floor being built up with dummy sides to hold it all together. The sides will then be painted body colour and when fitted will be just about invisible. I will post another photo when it is finally painted, I use Games Workshop acrylics for this and treat it like a big figure.

And finally some me time.  Back to the Britannia. As I have said before I bought this loco part finished. This is what we have so far. It does seem square and well made to the drawings with a lot of the fiddly things like the riveting and bending of the tank sides already done. I will have a good look over it and check it with a ruler to make sure all is well. I'm sure it will be, the previous builders have usually done a very good job. All in all a lot of work already done.

It is well tarnished at the moment so one of the first things to do will give it a good clean and make it nice and shiny. I have already started going through other peoples build threads to try and work out a plan of attack. I have also had a good look at No23mk2's You Tube channel where he has put together a BR1D tender to the Les Warnett drawings, very useful.

This also came with the loco, a hand pump in a curious little tray which I can't find anywhere on the drawings. It may just have been from another project and allocated for this one at some time. I'm not sure if it is home made or a commercial offering. One of my first things will be to take it apart and give it a once over and make sure it works o.k.

Finally, thanks to Delaplume on here, this is a present from Father Christmas for the front of Flying Dutchman. 70018 was a regular on the Red Dragon when it was a Western Region loco, which is how I intend to finish her as running in 1955. I know about the wonky handrail, it wasn't me, honest. it will be corrected when I get round to the engine.

All the best to you all.

Mike.

|

|

|

|

Post by Deleted on Jan 17, 2019 12:48:38 GMT

That's nice Mike, good to see you back on 70018, that tender looks very well built to me so I think all will be fine. The headboard adds to a model doesn't it, looking great... I like the A4, I think that I mentioned in the past that I'm building the 'Partworks' kit, I haven't done anything on it for at least a year, perhaps mor...here's a picture I just took to show how far I have progressed, a long way to go still, the roof isn't attached yet as I was working on the backhead, one day I'll get back on with it and also make a start on the Martin Finney A1 that I have too..  Cheers Pete |

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Jan 17, 2019 13:04:47 GMT

Hi Pete

Thanks for the kind words. The A4 looks very good. I think the part works kit was done by DJH like my A4 but obviously to a price. The body shell does look very familiar. If you like I can take some shots of the sub assemblies to show my modular method of construction.

Mike

|

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,990

|

Post by JonL on Jan 17, 2019 14:25:44 GMT

Fantastic work. I'd like to see the modular construction.

|

|

|

|

Post by Deleted on Jan 17, 2019 14:57:13 GMT

Hi Pete Thanks for the kind words. The A4 looks very good. I think the part works kit was done by DJH like my A4 but obviously to a price. The body shell does look very familiar. If you like I can take some shots of the sub assemblies to show my modular method of construction. Mike I would love to see them, Mike, yes I think it is based on the DJH kit. I have added a few details using Laurie Griffen castings, I also have Premier rods and motion to use when I get to that stage, I have everything bar paint to complete the model, hopefully, I'll get it finished one day. I can't fault the kit, it's very well designed with, from what I can see, full detail as per prototype. Mind you I still have a long way to go so we shall see/ Pete |

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Jan 17, 2019 16:58:39 GMT

Modular construction of O gauge locomotives. Here is my take on putting together an complex O gauge locomotive. At times it can be a bit of a heart in mouth process taking a hacksaw to a £500 kit but at the end I have a kit that can be totally stripped down which makes painting and any subsequent repairs a lot easier. These photos go with the others in the previous post to show how I have made up the kit into sub assemblies, some screw together, others merely clip on.

This is the chassis at a quite advanced stage minus the bogie and Cartazzi truck.

This is the under side of the chassis. The wheels are held into the hornguides by what I call keeper plates. You will notice that the front two axles are held in place by one screw through a plate between them. To this is attached the springs, brake pull rods and cross shafts all in one unit. Just screwing this in place holds the wheels and axles in place. The rear wheel set is held together by the plate with the two screws in it at the rear This also has the springs attached to it on lengths of wire and holds the wheels in place when fixed. This does require a degree of forward planning and extra work but means I can remove all the wheels, complete with rods and if so modified the cylinders all in one go. In this instance the cylinders and motion screw on separately.

Here are the cylinders with motion attached ready to be screwed on plus some of the other rods and motion all ready.

These are the front bogie with holes ready for the side control springing and the Cartazzi box for the rear, all assembled as per the kit instructions in this case but as I would have done it anyway.

These are the brakes for the chassis made up into a clip on unit ready to be sprung into place. A lot easier to paint like this.

This is the tender, more or less made up as per the kit instructions.

and the chassis ready to go underneath. I needed to modify the brake pull rod so the chassis could be dropped out in this case, the kit instructions would have had it all locked together.I hope this gives you an in-site into how I make up my locos as sub assemblies. It does require a degree of forward planning but I think that the advantages are worth it. If anyone has any questions or points that need clarifying, please ask.

Normal service should now be resumed, back to the Brit

Mike

Mike

|

|

barlowworks

Statesman

Now finished my other projects, Britannia here I come

Now finished my other projects, Britannia here I come

Posts: 878

|

Post by barlowworks on Jan 17, 2019 17:11:53 GMT

Just to prove I don't just make blue engines, here is one that will be in BR green (when I find the annoying short circuit that keeps upsetting the sound system).

And one that isn't a loco at all. This is a Craven Brothers 25ton steam brake down crane. Fully working and with authentic steam crane sound.

Mike

Now back to the Brit, promise.

|

|