mbrown

Elder Statesman

Posts: 1,790

|

Post by mbrown on Dec 27, 2020 21:26:43 GMT

Incidentally, a number of articles I have read about using LEDs for loco lighting suggest putting a resistor in the circuit somewhere.

I am completely ignorant of electronics in all its guises. Can anyone here enlighten me as to why a resistor would be helpful in this sort of application?

Thanks.

Malcolm

|

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,990

|

Post by JonL on Dec 27, 2020 22:05:08 GMT

A resistor (usually in this case called a ballast resistor) provides a little resistance to prevent the LED being blown (it has so little resistance of its own that the battery sees it as a dead short and dumps all the current through it at once without a restriction!). Think of it as throttling back the hose-pipe so you don't blow your geraniums into the neighbours garden.

They are also normally used to get the input voltage down to what the LED requires. There are websites that tell you exactly which resistor you need based on the LED you have selected. One word of caution though, the resistors are starting to get quite big from 1/2 a watt upwards, and can generate a bit of heat if you are asking them to drop any serious voltage, so try and pick a supply voltage similar to the LED voltage to keep the resistor a sensible size.

I'm happy to help guide if you need tips on which LED's to go for etc.

|

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,990

|

Post by JonL on Dec 27, 2020 22:06:42 GMT

One more thing, the resistor is not suggested, it is mandatory unless you use some other form of current regulation. Without it the LED will almost certainly blow unless you are using a supply (such as a coin cell battery) which isn't capable of supplying enough current to pop it.

|

|

mbrown

Elder Statesman

Posts: 1,790

|

Post by mbrown on Dec 27, 2020 22:40:30 GMT

Many thanks Nobby, much appreciated. I may well be coming back to you for further advice when I start work on this little generator. I suspect I was off school the day they did electricity, let alone electronics....

Maybe all the electronics wizzards out there will say if thete is more I need to onow.

First, though, I need to make the turbine so that I can discover what the output is...

Best wishes

Malcolm

|

|

|

|

Post by Roger on Dec 27, 2020 23:15:15 GMT

Many thanks Nobby, much appreciated. I may well be coming back to you for further advice when I start work on this little generator. I suspect I was off school the day they did electricity, let alone electronics.... Maybe all the electronics wizzards out there will say if thete is more I need to onow. First, though, I need to make the turbine so that I can discover what the output is... Best wishes Malcolm This is a terrific little project. You can use an online calculator such as this one if you don't want to work it out from first principles. You will need a separate resistor for each LED so that each one has a current limit. The voltage you get from the turbine will depend on the RPM and also the load you put on it, so it's not that simple. I think you will have to experiment with different resistors to get the amount of light you require and at what RPM. You could start with something around 4K7. |

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,990

|

Post by JonL on Dec 27, 2020 23:19:19 GMT

The loaded output may vary wildly from the unloaded output, so once you know the voltage it puts out without any load try putting a simple load across it, such as a bulb, and see what it produces then.

|

|

|

|

Post by Roger on Dec 28, 2020 8:43:15 GMT

The loaded output may vary wildly from the unloaded output, so once you know the voltage it puts out without any load try putting a simple load across it, such as a bulb, and see what it produces then. It might just be easier in the end to go for a constant current circuit on the output of the generator so that the voltage doesn't matter. That can be as simple as just four components lashed together in a 'birds nest'. If you drive more than one LED you'll still need a separate series resistor for each LED, but the brightness will be independent of what the generator is outputting so long as it's enough to drive them. Modern high efficiency types of LED take very little current. The little integrated circuit I used in my lamps is ideal for this, but the package is too small to be easily soldered manually. Each chip handles two LEDs and the current is set by one resistor. |

|

mbrown

Elder Statesman

Posts: 1,790

|

Post by mbrown on Dec 28, 2020 11:40:53 GMT

Thanks Roger,

I was so chuffed when I spun the rotor and the LED lit up, I assumed it was going to be easy from there on.... ! Believe me when I say that my knowledge of electronics is ziltch - Nobby's metaphor of the garden hose is just at my limits.

I was dreaming of having all three headlights, three cab lights and a tail lamp all operating off the generator and switched in and out from the switch box in the cab as on the real thing. I may get there eventually, but I probably have to learn to walk before I can run. There is the added question of where to put any circuitry as suitable hiding places on the loco are few and far between.

In due course I will have a go at the turbine, then I can check the outputs - at which point I expect I will be back on the forum for more advice!

Malcolm

|

|

mbrown

Elder Statesman

Posts: 1,790

|

Post by mbrown on Dec 28, 2020 12:10:32 GMT

Although my little generator has no markings on it at all, a search on the web seems to have thrown up something which appears identical as far as external dimensions and overall appearance are concerned. The big shock is that it is shown on this US website as costing nearly 800 dollars! I couldn't have paid more than a couple of pounds for mine....

In terms of spec, it is shown as giving 3v DC/ 1000 rpm with a maximum speed of 12,000 rpm. My test with the turbine all those years ago seemed to give a pretty high level of revs (judging by the sound!) and it currently lights one 3V LED quite nicely when the wheel is flicked by hand. So I see I shall need to do some careful calculations when then turbine is connected up.

Meanwhile, I shall guard it carefully - if I lose or break it I can't afford a new one!

Malcolm

|

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,990

|

Post by JonL on Dec 28, 2020 16:13:24 GMT

I think this is a fantastic project. Can't wait to see how it pans out. Lighting the locomotive in this manner brings a smile to my face.

|

|

|

|

Post by steamer5 on Dec 28, 2020 20:56:10 GMT

Hi Malcolm,

Dad has a turbine on his loco, sounds great when it’s running! An issue he has that it’s speed goes up & down as the steam pressure changes!

I’ll have a chat with him if you like as one of the guys in the club helped out with a circuit board to even out the voltage, he doesn’t run LED’s so likely not quite what you need but I’m sure somebody here will be able to help out!

On the generator front, have a look out for a hand powered torch, I’m sure it will be way cheaper than the 800, not sure of the size as I haven’t pulled the one I have apart yet!

Cheers Kerrin

|

|

mbrown

Elder Statesman

Posts: 1,790

|

Post by mbrown on Dec 28, 2020 21:02:37 GMT

Thanks Kerrin,

Actually, I have the insides of a hand powered torch but it isn't the right shape or size! As I have the little tacho jenny, I am thinking out the system around its dimensions.

I was actually wondering about using grain of wheat bulbs as I have quite a few of them as used on model railways. But first I need to know the output of the jenny when driven by the steam turbine.

Details of a current stabilising curcuit would be very helpful - thanks.

Malcolm

|

|

|

|

Post by Roger on Dec 29, 2020 8:42:01 GMT

Thanks Kerrin, Actually, I have the insides of a hand powered torch but it isn't the right shape or size! As I have the little tacho jenny, I am thinking out the system around its dimensions. I was actually wondering about using grain of wheat bulbs as I have quite a few of them as used on model railways. But first I need to know the output of the jenny when driven by the steam turbine. Details of a current stabilising curcuit would be very helpful - thanks. Malcolm I think incandescent bulbs will draw too much power for your generator to supply. Less can draw just a few milliamps and still provide a lot of light.I think that's your best option with some simple circuit to get the most out of them |

|

|

|

Post by cplmickey on Dec 31, 2020 9:13:14 GMT

You will need a separate resistor for each LED so that each one has a current limit. The voltage you get from the turbine will depend on the RPM and also the load you put on it, so it's not that simple. I think you will have to experiment with different resistors to get the amount of light you require and at what RPM. You could start with something around 4K7. The most important thing is to regulate the voltage at the LED. Your LED needs about 2.2 volts in the forward direction so the resistor value needs to be chosen to suit the supply voltage to prevent the LED from being damaged. Take a look at this learn.adafruit.com/all-about-leds/forward-voltage-and-kvl - I've only chosen the second page but it's a really good basic introduction website. You will need to regulate the voltage so it can't get more than 2.5 volts say at the LED - less is fine although it will probably switch off at something like 1.5 volts. |

|

|

|

Post by keith1500 on Dec 31, 2020 14:48:23 GMT

|

|

mbrown

Elder Statesman

Posts: 1,790

|

Post by mbrown on Dec 31, 2020 17:42:18 GMT

Thanks for all the advice from the members who understand electronics! I am starting from absolute scratch but trying to absorb all the points and references you are giving me.

I am aiming to get my frames assembled, at which point work on the generator may well resume - I have already dug out some bits and pieces to make the turbine and housing....

Happy New Year to all.

Malcolm

|

|

mbrown

Elder Statesman

Posts: 1,790

|

Post by mbrown on Dec 31, 2020 18:08:37 GMT

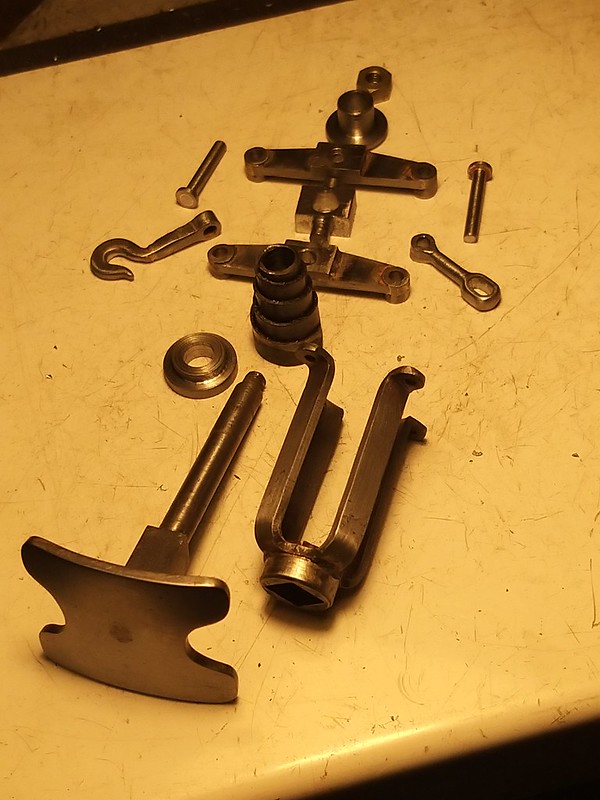

The last few days have been spent assembling the frame stretchers, but today I got tired of riveting angles and plates together - despite being nowhere near Mr Moses's record (see the thread on Riveting today!). Quite a while ago, I made the supports for the buffer couplers, so I thought I would finish them off as a change of activity. 99 3462 had a simple style of buffer-coupler found on some Continental systems, with a central buffer and chains either side, one side having a hook and the other the chain. These were attached to the ends of a pivoting arm, and the central spring took both the buffing and traction forces. The arms were pivoted to allow for curvature. On the MPSB, the chains were a motley assemblage of links - some round, some oval and usually at least one triangular which I suspect was used like a "instanter" coupling to adjust the length in use. Over the years, the details varied to some extent - there were at least two styles of swinging arm - and in preservation the whole thing was modified to accept the loop and pin couplings used by the WEM and the DKBM where she now is. I chose a style of arm with bosses at each end - the alternative would have been a kind of pressing with the ends bent downward. I thought the style I chose might be easier.... As they all needed to be the same length, I set out all four (two per coupling) on one piece of metal and drilled holes for the bosses on the mill so that the spacings were identical. Bosses were turned out of 1/4" BMS and pressed in, and a thickening piece added on the other side before silver soldering together. Here it is as it emerged from the pickle.  IMG_20201230_161133 IMG_20201230_161133 by malcolm brown, on Flickr This was then sawn into four pieces and each cleaned up on the mill and with files to look like this:  IMG_20201231_140440 IMG_20201231_140440 by malcolm brown, on Flickr The other components were straightforward. I made the volute springs ages ago. The hooks were adapted from some wagon safety chain hooks acquired years ago from Dave Noble when I was planning a wagon to go with Lyn (which never happened - but the wheel castings are now the tender wheels of 99 3462!). The slotted loop on the other side is actually a wee bit over scale thickness - I am amazed at the size of trains that this loco pulled on the MPSB coupled only by quite flimsy chains and attachments, and with no continuous brake. I won't be relying on the hooks and chains for passenger hauling, however. Here are all the bits for one buffer coupling laid out in the order they go together:  IMG_20201231_152618 IMG_20201231_152618 by malcolm brown, on Flickr And here is the other assembled to the front buffer beam....  IMG_20201231_162240 IMG_20201231_162240 by malcolm brown, on Flickr I haven't made the chains yet. Back to the riveting tomorrow, I guess.... Happy New Year to all. Malcolm |

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,990

|

Post by JonL on Dec 31, 2020 18:31:17 GMT

I wouldn't have thought of doing the bushes first but it makes perfect sense. Lovely job there.

|

|

|

|

Post by Deleted on Dec 31, 2020 18:39:40 GMT

Top job Malcolm, a truly lovely piece of work...

Pete

|

|

mbrown

Elder Statesman

Posts: 1,790

|

Post by mbrown on Jan 2, 2021 21:53:42 GMT

Several days in the workshop have seen most of the frame stretchers completed. It all took a lot longer than anticipated - but all the angles had to be machined down from thicker black mild steel sections or cut out from square steel tube. I just don't like drawn brass angle in frame construction (just a prejudice really - none of this will be visible when the loco is finished). The bolts (rather than rivets) on one of the angles are as per prototype - no idea why! There are still a couple of smaller stretchers to do, and a long horizontal one that will link the tops of three of the transverse ones. But I have run out of 5/64" rivets until I can assemble an order for stuff from EKP Supplies.  IMG_20210102_175227 IMG_20210102_175227 by malcolm brown, on Flickr The one at bottom left sits horizontally under the rear of the loco and carries the coupling pocket - same as the one on the tender. Best wishes Malcolm |

|