|

|

Post by Jim on May 18, 2014 12:39:57 GMT

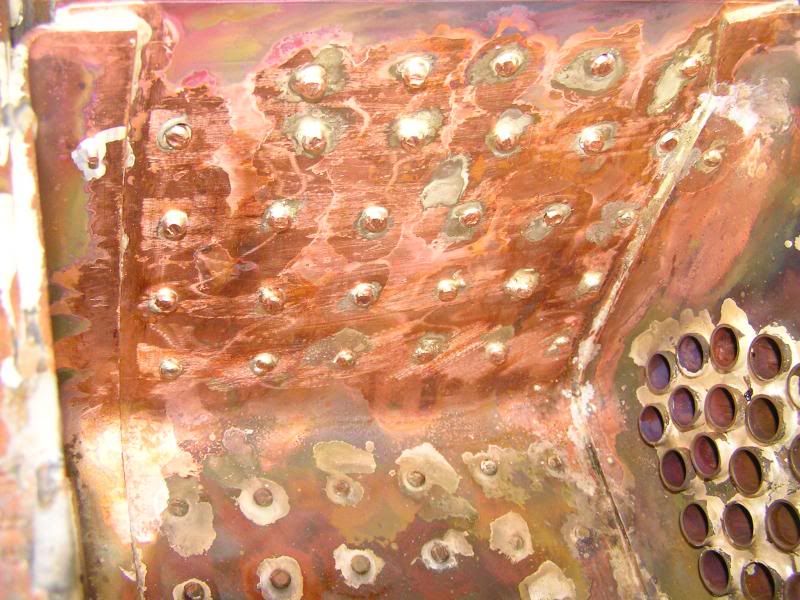

Thanks Wilf I'd be interested in the settings your friend uses for the oxy propane, especially in judging the correct flame. This is today's effort. Two stays could do with more attention, it's not easy to see how things are going as you work further in especially given the all encompassing flame. A check with a torch into the water cavity shows the silver has penetrated nicely through the joint.  Jim |

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on May 18, 2014 22:17:54 GMT

hi jim,

looking very good! you arent far off now to completion!

cheers,

julian

|

|

|

|

Post by Jim on May 19, 2014 0:02:00 GMT

Thanks Julian for your comment. There are a couple of 'patchy' bits I'm not happy with and will get back to today but overall things seem to be going well. As I mentioned earlier I'm still finding my way with the oxy-propane but I feel it has the 'softer touch' of the traditional propane torch compared to oxy-acetylene and it's potential for making melting moments of the non biscuit kind.

Jim

|

|

|

|

Post by Jim on May 21, 2014 5:19:35 GMT

Two sides and the crown have now been done with the backhead to do next. Once they are done I can then turn to the outside and do the stay tails. The new oxy-propane torch is now producing a good soaking heat as I get a better feel for the gas settings. The photos show progress to date, with only one side to go along with a re do of any stays I'm not happy with.  the outer 'tails' haven't been done yet.  Jim |

|

Geoff

Hi-poster

Posts: 171

|

Post by Geoff on May 21, 2014 5:29:36 GMT

Looking superb Jim!

Forgive me if you have mentioned this in in one of your previous posts .... what solder and flux are you using and where did you source them from in Oz?

Cheers

Geoff

|

|

|

|

Post by Jim on May 21, 2014 7:40:52 GMT

Thanks for the comment Geoff.

I'm currently using J Mathey's Esyflo SB flux which I got from BOC. The solder is cad bearing SB45 1.6mm x 175mm from Wayne Roberts at Model Engineering Supplies in Melbourne. There could be other suppliers of silver solder and now I think of it BOC probably carry it too. My old club used to carry stocks which they then sold on to members but I think that has stopped now.

Jim.

|

|

robmort

Hi-poster

3.5" Duchess, finishing 2.5" gauge A3 and building 3.5" King

3.5" Duchess, finishing 2.5" gauge A3 and building 3.5" King

Posts: 174

|

Post by robmort on May 22, 2014 10:56:38 GMT

Very neat work.

Did you apply the silver solder to each internal stay head in turn, or did you put solder rings on them somehow?

I see no easy way to put rings on these, but I find that when doing each by hand it's difficult to work fast enough on so many joints, and be accurate in placing the stick on the heads, without burning hands or melting the whole stick.

Nearly all the texts on boiler making skip over these practical issues.

Rob

|

|

|

|

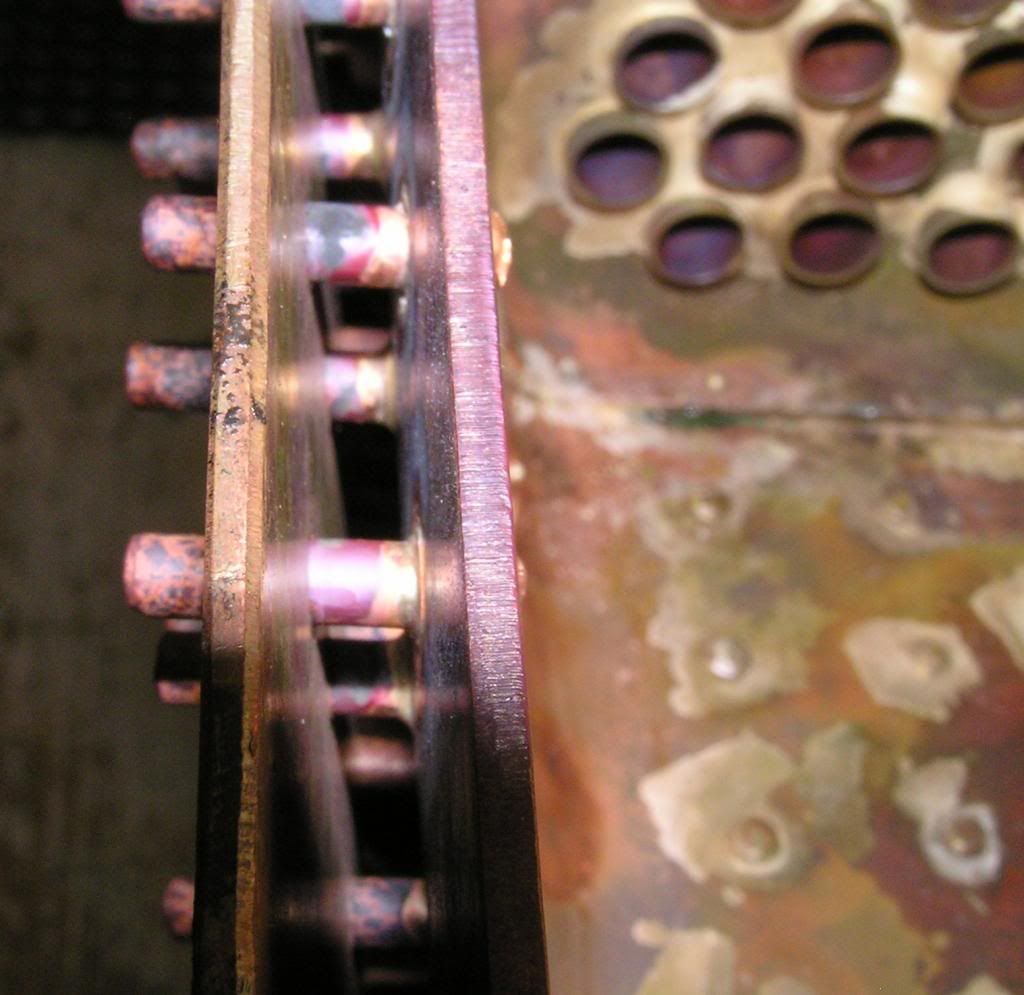

Post by Jim on May 22, 2014 11:47:34 GMT

Thanks for the comment Rob, the work is slowly getting better as I get a better feel for the oxy-propane torch's best settings. In answer to your question, to stop the stays dropping through I lightly peined the heads of the stays in the chuck while running the lathe, slow tedious work I must say, there's a photo here. modeleng.proboards.com/post/89192/thread I then made up a pile of silver solder rings by winding the wire round a suitable bit of rod as you would to make a tight coil spring, then snipped the coils to create the rings to slip onto each stay before feeding it through the appropriate hole in the fire box. I should add all the stay holes were counter sunk for the silver solder to form a fillet round the stay. I also had a stick of solder to hand to add a bit of extra solder if I thought I it was needed. At times I find that a real problem as, probably due to nerves, my hand starts to shake and the rod wobbles all over the place but nowhere near where I want it.  As I said earlier I will have to go back and redo some stays that I feel need it. As you've noted it's hard to keep track of where you are in the heat and glare. Jim |

|

Geoff

Hi-poster

Posts: 171

|

Post by Geoff on May 23, 2014 7:38:20 GMT

Jim,

Did you countersink both the inside and outside of the plate?

Cheers

Geoff

|

|

|

|

Post by Jim on May 23, 2014 8:07:49 GMT

Jim, Did you countersink both the inside and outside of the plate? Cheers Geoff Hello Geoff, I counter sunk all the stay holes on the inside of the fire box and on the outside where they exited the outer wrapper. This afternoon I completed silver soldering the backhead stays on the inside of fire box which completes the the four inner firebox sides.  At last I think I have the correct torch settings to the point that once the first stay is up to heat things just flow on as you work along the row of stays. Unlike oxy acetylene the oxy propane is a really soaking heat. The next task will be to tackle the outer ends of the stays then on to the foundation ring. I'm actually enjoying boiler making...never thought I'd say that.  Jim   |

|

|

|

Post by Shawki Shlemon on May 23, 2014 9:50:28 GMT

You doing great Jim , When you finish this you will realise that the boiler is not the hardest part to make .

|

|

|

|

Post by Jim on May 23, 2014 10:03:46 GMT

Thanks Shawki for the encouragement, your comments are much appreciated. Now I have the gas settings sorted the oxy-propane really puts out the heat and unlike oxy acetylene is much more of a broader soaking heat rather than a very concentrated heat. I like it.  Jim |

|

|

|

Post by Jim on May 24, 2014 6:11:43 GMT

Today all the stays in the fire hole plate were brazed in along with redoing the stays in the other sides that I wasn't happy with. Now the gas settings are sorted, thanks here too to Wilf and John for their input, the silver brazing is going a lot faster and much more effectively and efficiently. The next job will be to braze the stay tails into the outer wrapper and with this in mind I've started winding the silver solder wire onto a mandrel to create the rings of solder to drop over each tail. After many nervous starts and much procrastination the end is in sight at long last.  Jim  |

|

|

|

Post by runner42 on May 24, 2014 6:37:20 GMT

Hi Jim,

Still being impressed by your workmanship. I bet your pleased that the completed boiler is in sight, is all the boiler fittings completed so that completion is days not weeks away?

An asside you belong to the Orange ME Club which as you say is just 300Kms up the road. I assume that your club's boiler inspector is the one that is stage inspecting it as you go along so is your boiler the most travelled boiler in the history of model egineering?

Good luck with the testing.

Brian

|

|

|

|

Post by Jim on May 24, 2014 7:07:55 GMT

An asside you belong to the Orange ME Club which as you say is just 300Kms up the road. I assume that your club's boiler inspector is the one that is stage inspecting it as you go along so is your boiler the most travelled boiler in the history of model egineering? Good luck with the testing. Brian Thanks Brian, The boiler certainly has a few hundred K's under its foundation ring in fact about 1300kms, as I've taken it over for the club inspector to check the plates etc before joining then to check the joints and I'll be heading back for the hydrostatic tests but to save an extra 600km round trip on top of that I'll check that everything is sound before I go  I try and work the visits in with the club running day and depending on things we either stay overnight or go up and back in a day, it's 3 hours driving each way on very good country roads so not a problem. All the bushes are in and I have all the fittings ready to go so fingers crossed it might get finished before I'm too old to get it out of the pickle barrel.  Jim |

|

peteh

Statesman

Still making mistakes!

Still making mistakes!

Posts: 760

|

Post by peteh on May 24, 2014 7:15:48 GMT

Hi Jim,

Great work and great information on making your boiler. A question if I may - do you also pickle the silver solder rings to remove oil/grease from them as well. I have just formed my rins of solder for the Northumbrian boiler and had that questioning moment.

|

|

|

|

Post by Jim on May 24, 2014 10:21:54 GMT

Hi Pete, In answer to you question, no I don't put the rings through the pickle bath. The boiler goes in to clean off residue oxides and flux. I use citric acid which I get from the local supermarket, it's in the cooking needs section and comes in 75 g containers. I mixed it in a new plastic garbage bin of water and kept adding acid until the water had a 'citric' taste, very scientific I know but it works.  Your boiler must be getting close to the silvering up stage by now, if you haven't done so have a look a Julian's "Boxhill" thread for some very nice boiler work. modeleng.proboards.com/post/97613/threadKeep up the good work on Northumbrian. Jim |

|

peteh

Statesman

Still making mistakes!

Still making mistakes!

Posts: 760

|

Post by peteh on May 24, 2014 12:40:58 GMT

Thanks for that Jim, Started silvering this afternoon as it happens  |

|

|

|

Post by Deleted on May 24, 2014 14:23:52 GMT

looking great Jim....getting closer to testing...  Pete |

|

|

|

Post by Jim on May 25, 2014 22:14:50 GMT

So near and yet so far. Have to go and mind the grandchildren for 9 days...Oh the joy!  |

|