Andrew C

Part of the e-furniture

Posts: 447

|

Post by Andrew C on Aug 27, 2014 13:54:46 GMT

Hi Jim

The good news in the is that it is only 5 pin holes. Let's hope as you fix them they seal and others don't occur. Fingers crossed.

Keep up the good work major mile stone nearly complete.

On the weight side of things, everyone runs away at the mention of needing to lift Robert Burns.

I invested in one of these hydraulic lifting trollies worth it's weight in gold! Off the bench and into the car is fine. Just need to sort getting off the trolly to the ground level track and all will be happy

Andrew

|

|

|

|

Post by Roger on Aug 27, 2014 15:48:22 GMT

Hi Andrew, This is the setup used for a Hunslet and that seemed to get it off the carrying frame and onto the tracks very easily. The blue ramp detaches for transport  20140803_110907 20140803_110907 by rogerfroud, on Flickr |

|

|

|

Post by Jim on Aug 27, 2014 18:58:46 GMT

Good morning Roger and Andrew,

I have one of those hydraulic lifting tables too Andrew and as you say they're worth their weight in gold. I added an extension to mine so I could run the 3"Burrell up onto the table. A very useful item to have I must say for when needed and for the rest of the time a handy surface to put tools and bits while working on Boadicea.

That's a nifty looking lifting frame Roger, I like the transition ramp from the frame to the track. I'm going to need something similar to take the loco from the car to the club's traverser. But first there are some pin holes to mend and fingers, toes and anything else I can find will be crossed for the next test.

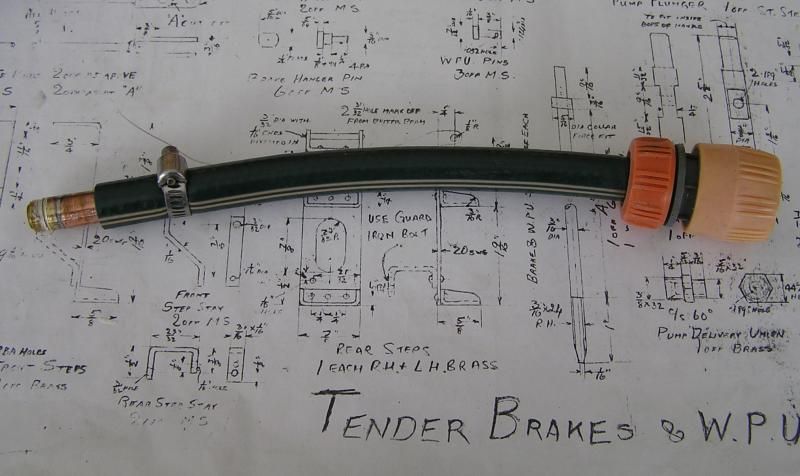

On the plus side the hose to boiler fitting worked well and for this exercise I also fitted the Everlasting blow down valve, filler valve and blower steam tube and all were water tight.

Jim

|

|

pondok

Part of the e-furniture

My 5" gauge SAR class 15F

My 5" gauge SAR class 15F

Posts: 359

|

Post by pondok on Aug 27, 2014 20:33:09 GMT

Roger, where is that track in your pic above?

|

|

|

|

Post by Roger on Aug 27, 2014 21:15:30 GMT

Roger, where is that track in your pic above? Ah, that's a private garden railway in Sussex. |

|

|

|

Post by Jim on Aug 31, 2014 12:28:24 GMT

Just a quick update. After getting a small pack of Cigweld 965 soft silver solder, as specified in the AMBSC Code for caulking, I started cleaning and caulking the 5 pin holes revealed in the first light pressure test Of course once I'd completed the caulking I had to do a second test which happily showed original pin holes were no more  but three more had been hiding in the fog of the first test including an almost invisible hole beside a tube in the fire box.  Having checked the code I'm assuming 965 can also be used in the fire box, I tried to check with our club boiler inspector but he's gone walkabout and won't be back for 2 weeks. Having taken forever to get this far I'm suddenly mad keen to get the job finished now the end is in sight. Jim. |

|

|

|

Post by Shawki Shlemon on Sept 1, 2014 10:12:03 GMT

Jim , the code does not say where to use it or not use it , however many many years ago i did use it for that purpose on few of my early boilers , then i discovered from experience while that is acceptable but if one need to do any job with silver solder later or after the use of 965 it becomes unpleasant experience so I never use it anymore on my boilers , I give the members same advice but if used I accept it , their problem not mine . We had couple very bad examples , the boilers never passed yet and I doubt they will ever do . hope yours is not like that because it looks very good from what I have seen .

|

|

|

|

Post by Jim on Sept 1, 2014 11:40:31 GMT

Thank you Shawki that is exactly the response I was looking for. I had a funny feeling about 965 even though it was in the code so I decided to 'wait and see' what you thought.

As always you're advice is much appreciated.

Jim

|

|

|

|

Post by Roger on Sept 1, 2014 13:08:47 GMT

Yes, thanks Shawki, that's another invaluable piece of advice squirrelled away!

|

|

|

|

Post by Jim on Sept 7, 2014 7:31:06 GMT

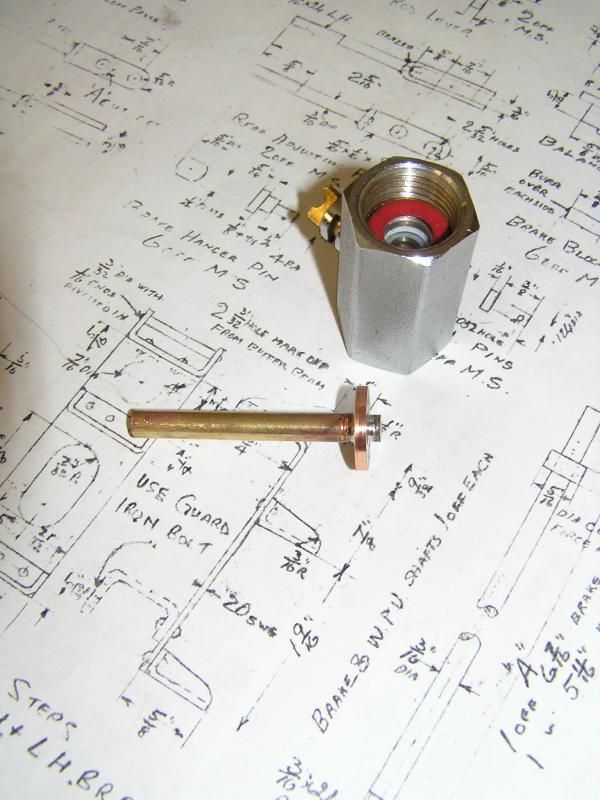

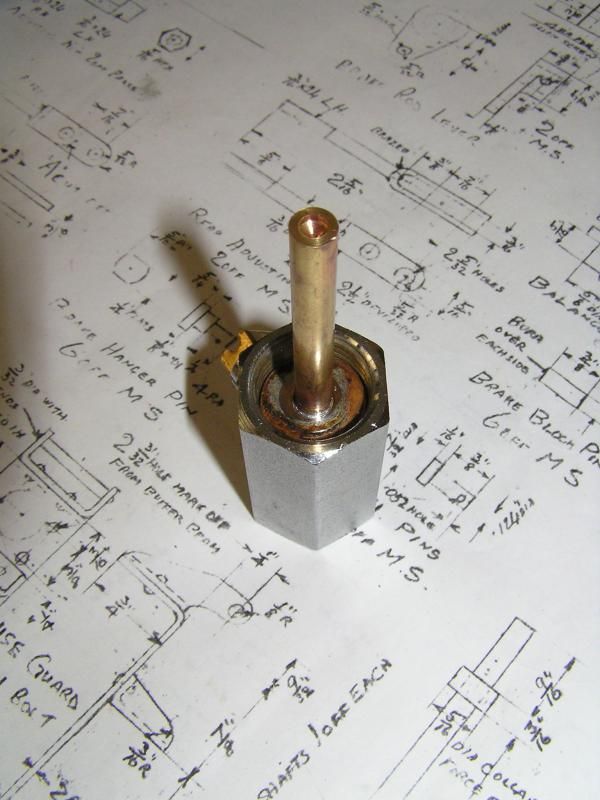

Not much has happened since completing the boiler other than making the blanking off plugs for the various bushes. A special disc was turned up on a brass rod mandrel to seal off the regulator. It wasn't used for my home test under water mains pressure but will be needed for the official pressure test. At present I'm waiting for the club boiler inspector to return from a trip up north. I need to discuss with him the best way of sealing the 5 pinhole leaks in the boiler. The photos show the disc made up to blank off the regulator bush, The brass rod acted as a mandrel while the disc was turned to size.   The mandrel will go through the bush into the boiler when the regulator is screwed onto the bush. Jim |

|

|

|

Post by runner42 on Sept 7, 2014 7:55:54 GMT

Jim , the code does not say where to use it or not use it , however many many years ago i did use it for that purpose on few of my early boilers , then i discovered from experience while that is acceptable but if one need to do any job with silver solder later or after the use of 965 it becomes unpleasant experience so I never use it anymore on my boilers , I give the members same advice but if used I accept it , their problem not mine . We had couple very bad examples , the boilers never passed yet and I doubt they will ever do . hope yours is not like that because it looks very good from what I have seen . Hi Shawki, I had first hand experience in using Comsol which I assume is a similar product to 965. It was due to poor housekeeping practices that I allowed a Comsol melt to remain on the hearth firebricks upon which I placed a brass assembly for silver soldering. At the silver soldering temperatures the Comsol attacked the brass and 'burnt' an indentation in the brass assembly. The same I assume will happen with copper. Brian |

|

|

|

Post by Jim on Sept 7, 2014 8:13:17 GMT

I don't know the composition of Comsol but Cigweld 965 is 96.5% tin and 3.5% silver according to the stats sheet.

Jim

|

|

|

|

Post by Deleted on Sept 7, 2014 8:36:44 GMT

Comsol is 93.5% lead, 5% tin and 1.5% silver.It melts at 296°C. It's the lead that affects silver soldered joints. Yours is obviously a lead free solder and I have read that that type of solder does not affect silver soldered joints and it is possible to re silver solder joints after that has been used elsewhere on the boiler.

I've never really understood the reason against using Comsol on a boiler as I don't see why there should be the need to use silver solder again on a boiler once it's completed. To me, it's much simpler to seal a few pin holes with Comsol etc. rather than try to SS them again and finish up chasing more leaks that occur when the boiler is reheated to SS temperatures again.

John

|

|

|

|

Post by Shawki Shlemon on Sept 7, 2014 9:37:03 GMT

John , I agree with what you say , the intention of the code is what you described but that may be stretched by some builder to more than a few minor leaks , the need to do more silver solder may arise for many reasons , adding a bush , fixing a leak in a joint particularly later and so on ,repair , It does happen , I have seen it happen .

|

|

|

|

Post by Deleted on Sept 7, 2014 17:06:09 GMT

Hi Shawki, I completely agree that the rest of the joints must be structurally sound and something like Comsol should never be used to cover up poor solder penetration. It's just that I have heard and seen where someone has had a simple weep from an otherwise good joint, tried to reheat it to silver solder again and finished up with more leaks than when they started  It's more of a problem when you are limited to propane only as you can't help but heat all the surrounding area as well. Jim should be better suited with his oxy acetylene gear as he should be able to keep the heat localised. I've managed to ss missing bushes into boilers with propane without affecting nearby joints but I was very nervous doing it! John |

|

|

|

Post by Jim on Sept 7, 2014 22:20:21 GMT

I think John may have hit the nail on the head. I've noticed that with the oxy-propane torch using a No 10 tip, the heat is very much localized and as a result I haven't had any problems with the heat effecting surrounding joints.

I must say I'm very happy with the oxy-propane for it's heating ability, the fact that I own the D size oxy bottle and just swap and go the same as with with the propane.

All that aside, as a first attempt at a boiler I'm still very nervous about the whole boiler making game.

Jim

|

|

|

|

Post by Deleted on Sept 7, 2014 23:19:44 GMT

Jim, Anyone who can tackle a 5" Brit boiler as a first build and get as good a result as you have doesn't have anything to worry about  John |

|

|

|

Post by Jim on Sept 8, 2014 0:21:01 GMT

Thank you John for your reassurance. I must be honest though and say it would not have been possible without the sound advice of members such as yourself, Shawki and Julian.

Jim

|

|

|

|

Post by runner42 on Sept 8, 2014 3:10:54 GMT

Hi Jim,

I agree with John it's a remarkable effort to have built a fairly large boiler as a first attempt and you have shared your progress with us which is invaluable source of information for the first time builder like myself.

I am interested to know how you conducted your preliminary leak testing, was it under pressure either water in the boiler or air under pressure in a water bath? If it was less than test pressure is it reasonable to expect that at a lower pressure that if shows to be water tight that it will pass the twice than operating test pressure? It says in the code that caulking material has no inherent strength so will it stand up to the higher pressure without problems.

Brian

PS I have realised that pin holes don't require strength so filling with caulking material is only a sealing medium.

|

|

|

|

Post by Jim on Sept 8, 2014 4:28:29 GMT

Hello Brian, I made up a simple garden hose adapter, I'm sure I saw it in AME, to fill the boiler. Then when full to capacity I turned off the outflow ie regulator to bring the boiler to water mains pressure, I believe it's about 50psi. That's when I discovered the pin holes  Once the current pinholes are sealed and without any other form of testing gear I'll have to wait until the official test to see if there are anymore leaks. Fingers crossed there aren't. Actually I'm thinking of making up my own test rig get the pressure up to 100psi but that's just a thought at this stage. Jim  |

|