tim

E-xcellent poster

Posts: 236

|

Post by tim on Feb 15, 2014 19:28:14 GMT

I had read it and was thinking of taking it from the wheels, but I will wait till I have a rolling chassis as at the moment it's all just words to me really!!!

Tim.

|

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Feb 18, 2014 9:45:52 GMT

Morning guys, I was hoping to pick the forum`s brains this morning!! I`m now at the stage of riveting the horns onto my frames, and as I have never done riveting before, I was wondering which was the best method of spreading the tails over, ie should I be c/sinking the backs of the holes and peening the rivet flush, or should I be doming it over so there is a round head both sides, or just spreading them over in a barrel form.( it doesn`t state on the drawings, only saying rivet to frames). Maybe I`m overthinking again, and maybe because they`re on the inside of the frames it wont matter, but I just want to be sure I get this part right from the start. I`m thinking domed heads would look the best but the other ways might be easier.

Thanks in advance for any advice.

Tim.

|

|

|

|

Post by Deleted on Feb 18, 2014 9:56:29 GMT

Hi Tim

Yes the drawings are a little vague on this.... if I was to do my tender again and if using rivets I'd countersink the frames. Do check that the rivet heads fit on the horns , IIRC the reason I chose slot less screws was the rivet heads for the size stated by Don were too big scale wise for the horns. If you decide on dome head they should be ok clearance wise as I managed to use nuts filed down on mine.

Regards

Pete

|

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Feb 18, 2014 11:01:09 GMT

Pete I went to Chronos at the weekend to buy bolts and rivets and tried both rivet and slotless screws in a horn, both seemed to fit so I went with the rivets, I did pick up some of the screws though as I'm planning to fix the horns to the frames with a couple of them whilst I rivet.

It sounds like there really is very little clearance in there since you say you filed down the nuts.That is close!!!

Tim.

|

|

|

|

Post by Deleted on Feb 18, 2014 11:16:43 GMT

Hi Tim

It's not so much the running clearance but more in getting the wheels fitted, once the axle boxes are in their normal position there is far more clearance but it's getting the wheel rims past the horn positions where things get a little tight. I had scraped my wheels a few times when fitting which wasn't a good thing for future maintenance with a fully painted model so played safe and filed the nuts down.

Pete

|

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Feb 20, 2014 9:57:42 GMT

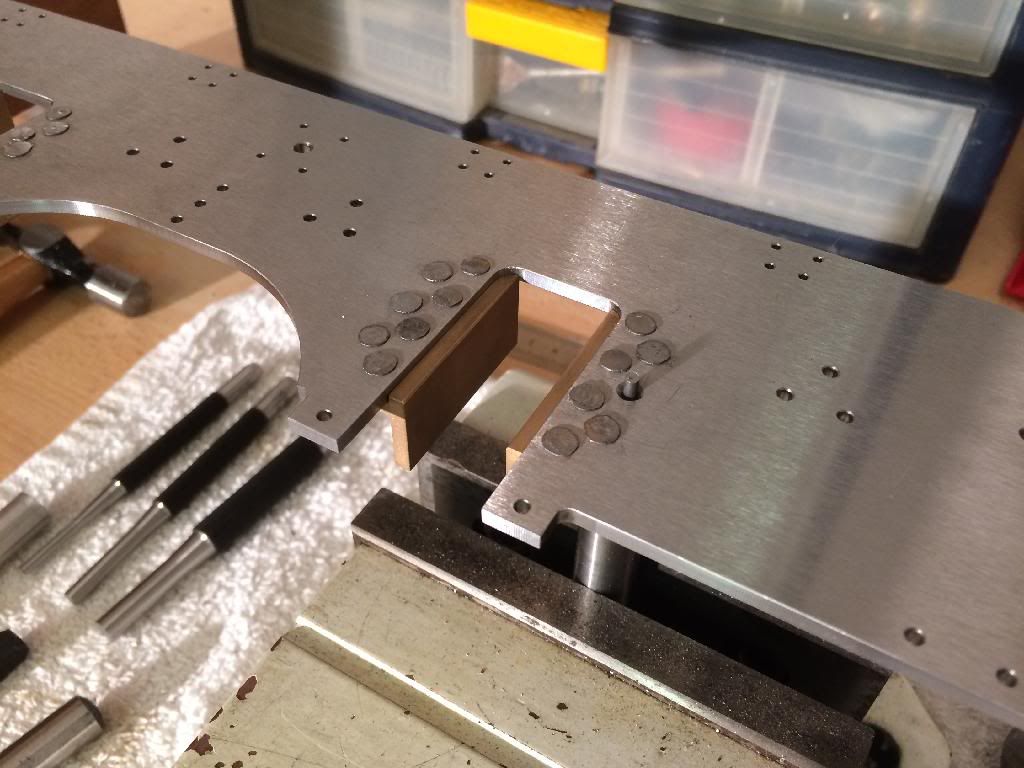

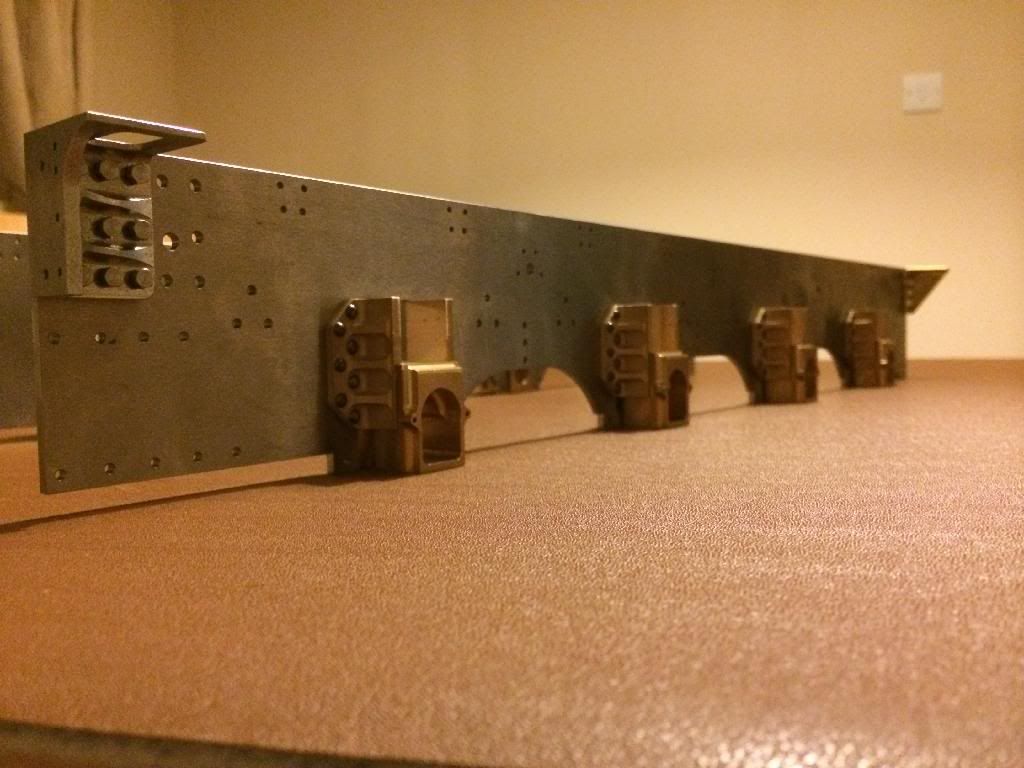

Just a small update whilst I prepare for the rivetting session ahead, the pair of rear outer stiffener brackets and the front brackets.   Tim. |

|

|

|

Post by Roger on Feb 21, 2014 8:05:10 GMT

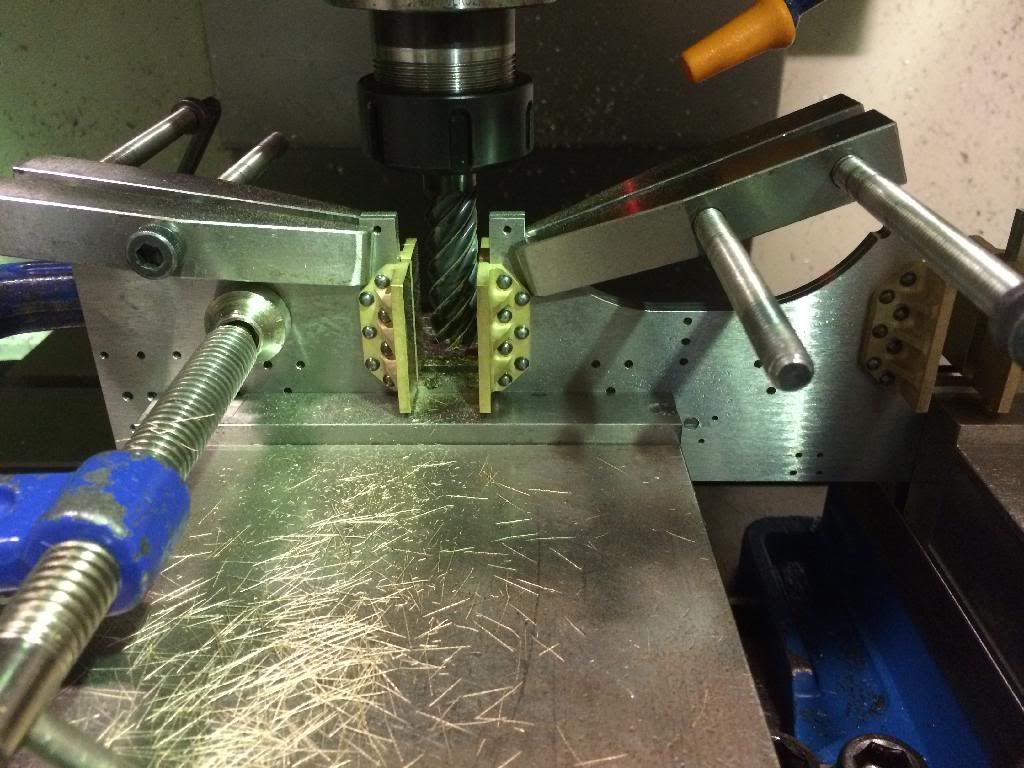

Those are very neat Tim, I take it you have a CNC mill by the look of the first picture? It's very well made especially considering the amount of tool overhang to reach the bottom of the flanges. Nice work.

Roger

|

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Feb 21, 2014 8:40:05 GMT

Yes I'm a CNC programmer setter by trade and I get to use them in my spare time quite a lot, they'll only get me so far though as I don't think I'll be able to escape needing some proper craftsmanship skills forever!!! And it looks like I'm going to need a lot of them after reading peoples builds on here.

Tim.

|

|

|

|

Post by Roger on Feb 21, 2014 9:23:57 GMT

Craftsmanship is certainly going to be necessary but you can overcome a lot of difficulties by using as much CNC as possible, particularly in getting the geometry of the axleboxes and horns right. I've only just started my build but you might find some useful ideas in my Wiki I've started for SPEEDY which you can find here... building-lbscs-speedy.wikia.com/wiki/Building_LBSC%27s_%27SPEEDY%27I'm just an amateur CNC user but I'm learning all the time. Roger |

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Feb 21, 2014 9:45:19 GMT

Cheers I'll give that a read, and yes I agree having access to cncs for a project like these is a godsent.

Its a pity you can't program them to silver solder and peen a rivet!!!!

|

|

|

|

Post by Deleted on Feb 21, 2014 23:07:54 GMT

Cheers I'll give that a read, and yes I agree having access to cncs for a project like these is a godsent. Its a pity you can't program them to silver solder and peen a rivet!!!! ---------------you mean like this >>>>>>>>>>>>>>>>>>>>>>>>> www.youtube.com/watch?v=wbd7XeRC6zk ---------------------- and this >>>>>>>>>>>>>>>>>>>>>>>>>> www.youtube.com/watch?v=AIwF1Hg65mg ........................... and while we're at it, how about a spoked wheel (bicycle or motorcycle ) built robotically ?? Take a ganda at this >>>>>>>>>>>>>>>>>>>>>>> www.youtube.com/watch?v=bPaa0lg4JBo ----------------- |

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Feb 22, 2014 0:23:42 GMT

wouldn't life be easy if we all had access to those Hagley lol.

|

|

|

|

Post by Deleted on Feb 22, 2014 8:53:00 GMT

Amen to that !!-----

|

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Mar 13, 2014 21:40:32 GMT

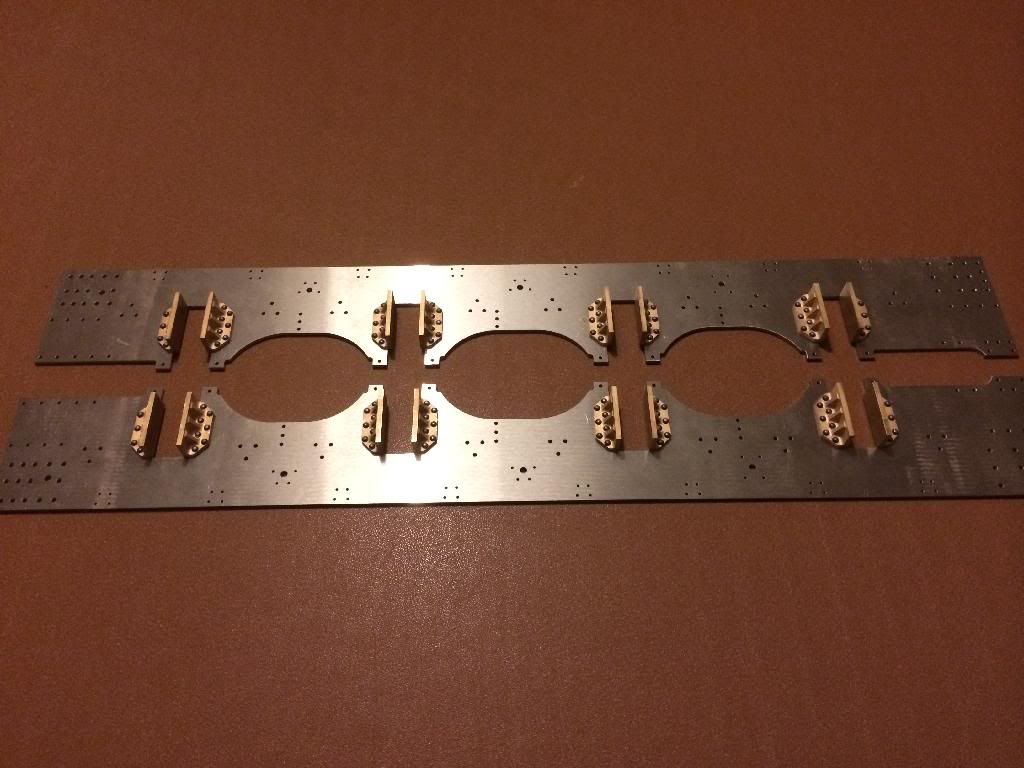

Evening all, finally finished the riveting of the horns to the frames, all 112 of them! I took the picture just before I did the last one, partly as a mini celebration to myself that the job was finished, and also just to show the set up. Next to do, and I'm looking forward to doing, is to file the rivets flush with the frames, secure them as a pair back to back and machine the horn faces to size to suit the axle boxes, which I have already made. Once that is done I believe I will have something resembling a tender frame. Tim.    |

|

shooter

Part of the e-furniture

If it 'aint broke....don't fix it!

If it 'aint broke....don't fix it!

Posts: 252

|

Post by shooter on Mar 13, 2014 22:08:16 GMT

Nice work Tim, wish my workbench was as neat & tidy.

Look forward to the next installment!!

Cheers for now.

Steve

|

|

|

|

Post by Deleted on Mar 13, 2014 22:24:22 GMT

looking good Tim... you'll soon have an erected tender chassis..

Pete

|

|

|

|

Post by Roger on Mar 14, 2014 8:25:53 GMT

That really looks the part. Nice one!

|

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Mar 14, 2014 8:32:29 GMT

Thanks Roger, Pete, and Steve, only half the bench is tidy mind, just the half in view!!!

Tim.

|

|

tim

E-xcellent poster

Posts: 236

|

Post by tim on Mar 15, 2014 22:55:49 GMT

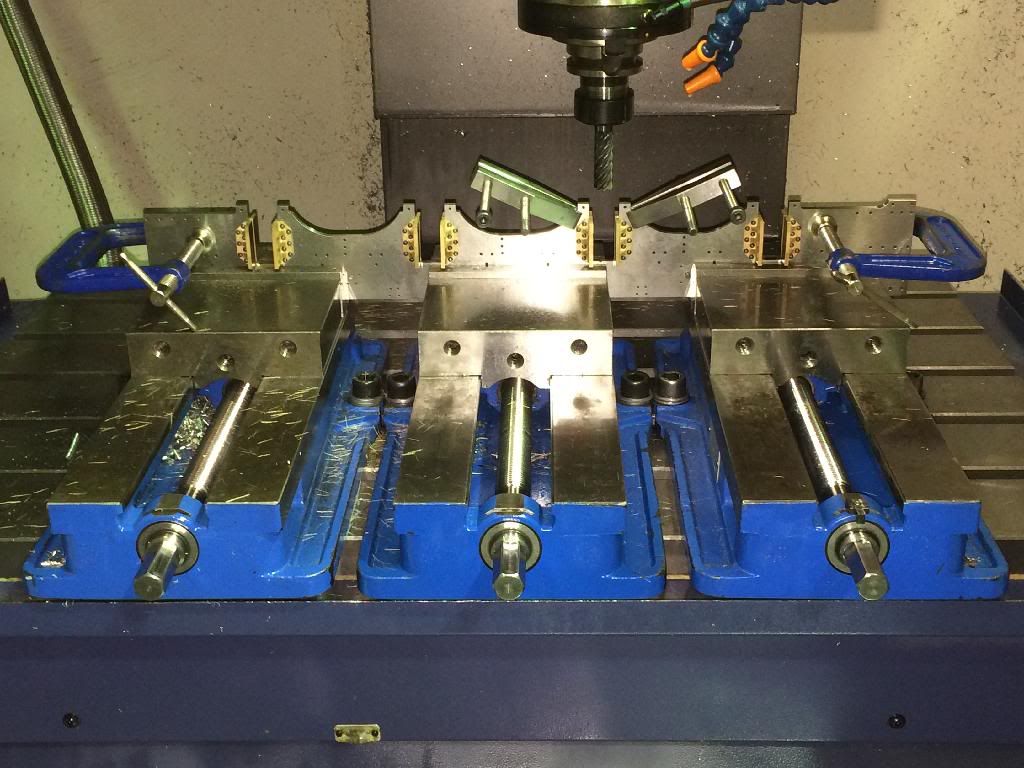

Hi all, just a small update for tonight, although it was quite a lot of work with a big setup for such a small operation. Anyhow all you guys have already been here so I will keep it short! Once the rivets were filed flush, I held both frames back to back aligned with dowels, and m/c'd the slots to suit the axle boxes. Finally whilst I was holding them this way up I squared the corners out where the horn stays will fit to the frames. Tim.     |

|

|

|

Post by RGR 60130 on Mar 15, 2014 23:32:18 GMT

Hi Tim,

It's looking good and coming on well. That's the worst bit done.

The machine vices you show look to be just what I need for my Triac CNC mill. You must like them or you wouldn't have bought 3. Could I be so nosey as to ask where you got them from? If you could post a link to a supplier that would be even better.

Many thanks,

Reg

|

|