kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Aug 3, 2015 17:05:05 GMT

12/11/15 Change to project title: See latest post for detail

Hi guys my name is Dave and I need some advice as a new starter to model engineering. At the weekend I sold my ‘hooligan’ car to finance a 5” gauge loco project and have some basic questions to help me plan things before I start spending money! However first a little bit about my background. I have an engineering background being a chief designer for the European aerospace division of an American filtration company. I have built a couple of racing cars from raw material and for the last 25 years have been railway modelling in 4mm scale, EM gauge. Currently I am finishing two multimedia kits of the LNWR 0-4-0 shunting engine and the crane tank for LNWR specialists London Road Models. However I have not twiddled the knobs on a lathe or mill since my undergraduate days in the late 1970’s, so the time has come to try live steam and I have decided 5” gauge is the size for me. Two reasons. First the size of the loco is not too big to handle and transport. Second the GL5 society has a lot of appeal, where trains are run for a purpose. Hauling passengers around every Sunday does not totally float my boat.

I have a good well equipped workshop, but do not own a Lathe, Mill or propane brazing equipment. As Warco are relatively close to where I live and they have some good offers at the moment, I will probably buy from them. I am trying to work out what I actually need as a minimum to buy and some advice from the members of the forum would be greatly appreciated. My initial thoughts are:

Warco WM250 lathe. This comes with 3 and 4 jaw chucks, fixed and travelling steadys and a couple of dead centres. I recon I need to add as a minimum, running centre, face plate and tailstock drill chuck. Cutting tools not sure which way to go here, carbide insert, HSS, quick change?

Warco WM16 mill. I think I need to add a machine vice, parallels, clamps, rotary table with dividing head. Then do I need additional collets, fly cutter, what type of ordinary milling cutters and slot drills?

Warco 4.5” Universal Band Saw.

I have two initial projects in mind. I like tender engines so the first build project (assume I will spend some time learning how to use the machines) is a BR Class 2 to Don Young’s design, I know there is a lot of it (tender etc) but it does not seem that much worse to build than say a simplex? In 4mm scale I would normally build the tender first anyway to get my hand back in! Are there known problems with the design, I already have a copy of Dons articles from L L and S? I have access to Catia V5 CAD, so I was going to buy the drawings and remodel the design in 3D to see if there are any hidden assembly problems, missing dimensions etc.

Castings, do I go for gunmetal or cast iron as it seems opinion can be divided on the subject?

The frames etc I will laser cut either using either proprietary ones or getting them done at work. The boiler I intend to have a go at myself as I do not have the budget to buy one. So what would be the best propane torch etc to start with?

If I finish the BR class 2, then as I have all the research work done, the second project would be the LNWR shunting engine to my own design, this would make a lovely little engine for what I would term a shunting plank in the garden (similar to the set up exhibited at the Warley Model Railway Exhibition at the NEC last year.

Obviously I need to join a local club, but have not decided who to approach yet. I am lucky enough living near Portsmouth to have the luxury of a number of local societies (Portsmouth, Chichester, Fareham, Southampton, even Guilford is only 35 minutes. So finding a club should not be a huge problem, says he hopefully!

Sorry to ramble on, but as this will represent quite a large financial outlay (I have management approval for it), I want to try and make sure I do not make any decisions at the start that may I may regret later?

Thanks in advance for any advice you have

Dave

|

|

|

|

Post by alanstepney on Aug 3, 2015 17:50:49 GMT

For some years I was a member of Chichester, and can say that it was a superb club, and would be my choice.

(I am assuming that it hasnt changed since I was there.)

Before buying machinery I would go to some clubs and ask people what they used to build their models.

Time spent on research is never wasted!

I have built several locos, (and 1.5 traction engines) using a Myford ML7.

That is about the smallest lathe you would manage with and something slightly larger would be better for 5".

A WM250 for example. A pal recently bought one and they seem a nice lathe.

|

|

|

|

Post by ejparrott on Aug 3, 2015 18:01:31 GMT

Our Chairman is ex-Chichester...possibly still is, he say's it's changed a lot sine he left.

On topic.

Well, what do you need...for many years the vast majority of ME's have cope with just a lathe and no mill, so if the saddle is suitable on the Warco, potentially you could save the expense. Personally, I'd far far rather have a mill. You'd probably get away without the faceplate, maybe even the fixed steady, but I'd have both. I've never used a traveling steady - never needed to. For me, carbide insert tools every time, and a QCTP, but it's not necessary. Ordinary HSS and a normal toolpost are all that most people have.

If you do go for a mill, I'd buy tooling as and when you need it as each job arises. Decide early on what type of tooling you're going to use though. For me, Metric and carbide are the only sensible choices. What toolholding depends a bit on the machine, ordinary collets for the R8 or MT spindle will do you well. My mill is CNC so ER collet chucks are the order of the day for so the tool length never varies.

|

|

|

|

Post by Roger on Aug 3, 2015 18:08:46 GMT

Hi Dave,

You're in a very similar situation to myself, and I'd strongly advise that you do indeed 3D model everything that you intend to make before you start cutting metal.

You've also fallen into the same trap as me in thinking that a 5" gauge locomotive will be easy to handle and transport. I'm building a version of SPEEDY, a 0-6-0 tank locomotive that's going to weigh in at 50kg when it's finished. That's way to heavy for one person to move about and lift into a car. You'll find that a tender locomotive is going to weigh a lot more than that and it will probably be too long and high to fit in many cars unless the seats fold flat and there's a good clearance above a flat loading area. You may be lucky and have a suitable vehicle but if not, it's a trailer job. Don't underestimate the amount of work in a tender locomotive either, it's a lot more than a tank locomotive. You're looking at a probably a 5 year plus project here so be sure you really want to commit to something that's ambitious and may not get finished. Heaven knows how many projects never make it to the tracks, but it's a lot.

There are strong opinions on most topics so you'll have to hear all the arguments and weigh them up for yourself. You'll certainly need to join a club to get the boiler design approved and inspected at each step. Don't assume that the drawings will meet the current regulations, they almost certainly won't. Also don't assume that everything on the drawings is set in stone, is sensible, or looks like the real thing if you're making a model of a real locomotive. These designs mostly date back 50 years or more and most have errors and omissions. Very few of them will have been updated to reflect the errors discovered. Don't assume that because dozens have been made that you'll easily spot those issues or be guided to them. Feel free to modify things to suit your own purpose. I've ignored the plans on almost every part and done my own thing because my plans don't look like the real thing and I wanted to use all Metric measurements and stock materials. Don't assume that you have to use all imperial sizes, there are metric equivalents for anything you'll need and suppliers on mainland Europe can supply whatever you require.

Anyway, best of luck with your project, you're going to learn the hard way just like I have but it's been a great experience so far. Most people here are very helpful and knowledgeable but sadly some will just snipe at you. It's a sad fact of life I'm afraid so don't expect it all to be positive and friendly.

Cheers,

Roger

|

|

|

|

Post by Rex Hanman on Aug 3, 2015 18:40:42 GMT

Hi Dave,

I am lucky enough to have what must be one of the finest examples of the Don Young Class 2 engine. I can say that as I didn't build it.

You are welcome to come and see it if you want to get a better idea of what's involved, which is a lot more than a Simplex, and there's plenty in one of those! I live in the Hampshire/Wiltshire area so I am not a million miles from you.

It will fit in the back of most cars if you split the loco and tender, but it is a heavy beast!

As Roger says, don't be put off by negativity, it is a lovely engine to model. With your skill set you will be able to adapt and meet the new challenges, of which there will be many.

I'm not sure you would need a dividing head, a rotary table would meet most of your needs.

Good luck, and please post a build thread.

Rex

|

|

|

|

Post by chris vine on Aug 3, 2015 20:03:49 GMT

Hi Dave and Welcome to the forum. Also, welcome to model engineering, it will keep you grey matter from going rusty...

Just two detail thoughts spring to mind on machines:

1

For a lathe, I would recommend you go for a belt drive machine as opposed to a geared head. They are much quieter and so more pleasant to use in a domestic-ish environment. Also more robust with no gears to damage etc. The same applies to the drive for a mill.

2

for the mill, it might be helpful to have one with an R8 spindle (mine has int 30 which is difficult to get hold of cheaply!). The advantage of the R8, is that you can mount smallish cutters direct in the R8 collet with almost no overhang and maximum rigidity and no loss of vertical height/space. A friend has a mill with R8 and it is a great set-up from that point of view. I am sure the Roger and Ed will have views on the choice of spindle taper as they are using machines all day every day, but that is just my thought!!

Have fun

Chris.

|

|

|

|

Post by Deleted on Aug 3, 2015 20:22:36 GMT

Hi Dave welcome to the forum and congrats on your choice of designer in Don Young, although he's not infallible you are less likely to come across any major errors in his drawings and his designs tend to follow very closely the full size prototype and thus look the part. I have the Warco WM16 mill myself which i find more than able to do the work required for our purpose's, I would advise getting a DRO is possible ( still on my wish list) or if not at least a set of digital scales. I have an older Warco lathe combi in the WM300 which I originally thought would be good enough for both lathe and milling work, for lathe work it's great and easily big enough for anything found on a 5" model including the smokebox at a push, but lacking in the mill department hence my later acquisition of the mill. As stated there's nothing quick in building a live steam locomotive, more so one with a tender but if it's a subject matter that you have an interest in then it's worth the extra work involved and less likely to end up unfinished under a bench somewhere.

All the best for the build and please start a build thread so we can follow your progress, you'll find that it's also a good place to put any questions you may have during the build.

good luck

Pete

|

|

jma1009

Elder Statesman

Posts: 5,917

|

Post by jma1009 on Aug 3, 2015 20:30:54 GMT

hi dave,

welcome to the forum!

you have made a good choice in a Don Young design, though i will trot out my usual advice to beginners not to choose a piston valve loco or a boiler with a belpaire firebox and tapered barrel as a first attempt.

have you looked at Don Young's ETNA LNWR design in 5"g?

cheers,

julian

|

|

|

|

Post by Donald G on Aug 4, 2015 7:30:37 GMT

Hi Dave,

Julian is right, the Class 2 is a nice loco and the drawings are pretty good and accurate. I decided to make mine a tank loco, this required a whole backend chassis redesign, cab and bunker, all this took a long time to design but are now all built, also have the side tanks underway now.

Julian mentioned not making a piston valve loco, I would agree and I have actually built mine with Simplex cylinders, although a fair amount of work required, now I have a running on air chassis, it runs very well.

Good luck with your project, it will frustrating at times, but also very satisfying.

Cheers

Donald

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Aug 4, 2015 12:44:20 GMT

Guys

Thanks for the comments. Reference transport no problem I have large estate car, to transport 4 scale layouts around in. So as Rex says with tender off a loco will fit in the back side by side. With regards to timescale I am aware of the time frame and not by co-incidence have just completed 5 years scratch building my last exhibition layout, so I am used to fairly long timescales. The comments on the machine tools and tooling are really useful and are helping with what to buy first.

With regards to the 'first' project I am now in a quandary. I fancied a loco with outside valve gear, if you have put all that work in you may as well see it. I see Julian's point about the boiler and it has been in my mind , certainly a parallel non-Belpaire bolier looks a lot easier to build. However I am not so sure why piston valves are such a problem, can someone enlighten me please. Building a Precursor is a possibility, however if we are looking around, Don's L and Y Aspinal also has a certain appeal as well, especially as I did all the artwork for the L and Y societies 4 mm scale loco transfer range, they would easily scale to 5 inch gauge.

Rex I will probably take you up on your offer even if it is only to talk to someone who is used to running live steam. I will contact you separately.

I will certainly start a build thread once I have got organised.

Regards

Dave

|

|

|

|

Post by Roger on Aug 4, 2015 13:02:33 GMT

Hi Dave,

The problem with piston valves is sealing them. If you use a simple approach with a precision fitted solid bobbin, that can give good results until wear sets in. If you want to be more ambitious and use piston rings of some kind then there are a different set of constraints. If you opt for solid PTFE rings then it's possible to get them to seal but getting the fit right is tricky and they'll leak when cold. Some have used thin split PTFE rings but it's necessary to have a design where either the ring gap fully closes or there is some other arrangement to avoid the gap in the ring venting straight into the ports. PTFE expands a great deal when hot and that has to be factored in when designing any solution. I've designed a setup with concentric rings that I've shown on my build thread but that's unproven to date. The situation is totally different to having piston rings on the main bores where they don't have to control the escape of steam through a port.

There are some very clever and complicated systems of metal rings and sleeves used in full size prectice but I don't think these are really practical in 5" gauge.

The simplest solution is to use a solid bobbin but personally I don't find that satisfactory from an Engineering point of view since it's only going to leak more as time goes on. It's not a simple decision that you face if you opt to use piston valves.

|

|

|

|

Post by chris vine on Aug 4, 2015 15:28:49 GMT

Hi Dave,

There is an old maxim that "slide valves wear in while piston valves wear out!" the slide valve is pressed against the port face by steam pressure in the steam chest so (unless the surfaces become deeply scored though lack of oil eg) then any wear is just taken up by the valve moving in a bit. with a piston valve any wear tends to lead to leakage unless you use well fitted piston rings.

It also tends to be easier to mill the ports for a slide valve compared to the piston valve version.

Chris.

|

|

jem

Elder Statesman

Posts: 1,075

|

Post by jem on Aug 4, 2015 16:48:17 GMT

Go to the Thornbury show if you possibly can you will see lots of tools, and get lots of advice from buyers and sellers, also you can chat about building a model and so on.

best of luck

Jem

|

|

Midland

Elder Statesman

Posts: 1,875

|

Post by Midland on Aug 4, 2015 20:44:00 GMT

Guys Thanks for the comments. Reference transport no problem I have large estate car, to transport 4 scale layouts around in. So as Rex says with tender off a loco will fit in the back side by side. With regards to timescale I am aware of the time frame and not by co-incidence have just completed 5 years scratch building my last exhibition layout, so I am used to fairly long timescales. The comments on the machine tools and tooling are really useful and are helping with what to buy first. With regards to the 'first' project I am now in a quandary. I fancied a loco with outside valve gear, if you have put all that work in you may as well see it. I see Julian's point about the boiler and it has been in my mind , certainly a parallel non-Belpaire bolier looks a lot easier to build. However I am not so sure why piston valves are such a problem, can someone enlighten me please. Building a Precursor is a possibility, however if we are looking around, Don's L and Y Aspinal also has a certain appeal as well, especially as I did all the artwork for the L and Y societies 4 mm scale loco transfer range, they would easily scale to 5 inch gauge. Rex I will probably take you up on your offer even if it is only to talk to someone who is used to running live steam. I will contact you separately. I will certainly start a build thread once I have got organised. Regards Dave Dave, I must pitch in with a comment or two. First of all welcome too. Twenty years ago I had but looked at lathes being operated in various factories I was involved with and milling was a mystery (still is). However I had an engine hidden away from a divorce and new Wifelet recovered it for me and I joined Southampton SME. A lovely chap found a lathe for sale and I bought a ML10 for £350 with all sorts of gadgets and tools. So I set up in the garage and made a lot of swarf. I had an Aspinal in O Gauge, the MPD one from 40 years ago and loved it. A year or so later my wife bought me a complete set of castings for Don Young's Aspinal in an estate sale and that has been my project for, yes, twenty years!!! Of course in the meantime I have fixed the Princess and bought a Midland Compound and through fixing them learnt quite a lot. Ed Parrott solved a terrible problem with brake hangers for the Aspinal that I can explain to you if you like. Also had to abandon the hobby for some six hyears when I got a company to look after. So I suggest you do not worry about getting all the gear now, get what you need when you need it. People dispose of workshops on eBay, club members die, people hear you are looking for a such and such and give you one. I have an ML7 now and a very basic Warco mill, cost £790 I think. Your choice of machine tools is endorsed by the others so go with them. Come and join Southampton, you will be very welcome, start your Aspinal and we can make them together (sounds bit twee that) but I think a little competition might spur both builds on (and you would teach me lots!). The one aspect of the Aspinal is that it has not ever been written up in the ME mags. The Lanky was apparently written up in the states but I have not tracked that down. I am using Don Young’s write up of the ‘crab’ as a sort of guide along with Martin Evans Jinty. Also I know of one being built in Leeds so a mutual help society might be useful. If nothing else bung me a PM and you can come and see what a learners workshop looks like and have a cuppa!! Cheers David |

|

pault

Elder Statesman

Posts: 1,500

|

Post by pault on Aug 4, 2015 21:14:41 GMT

Hi Welcome to the mad house. Just to put a different slant on things I would suggest looking at secondhand light industrial machines. If you have the room something like a Colchester Student can be picked up say ex collage with all the extras for similar money to an ML7. Industrial mills can be a problem space wise but if you can fit one in you won't be disappointed. Lack of 3 phase can be overcome with inverters. Don't underestimate the cost of kitting out a machine with all new kit, especially if you want to buy quality.

As for the loco, I would use all iron castings, piston valves with Clupet rings are not difficult to make. After all you need to make a piston which works a piston valve is just two pistons joined together.

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Aug 5, 2015 19:56:24 GMT

Gents

Thanks for all the responses. I have some thinking to do and I will take up some of the offers of come and look see. With work, holidays and my 4mm scale exhibition commitments I do not expect to be able to make any purchases before November (Warco also have an open day on the 7th), so I will probably go quite for a while.

Dave

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

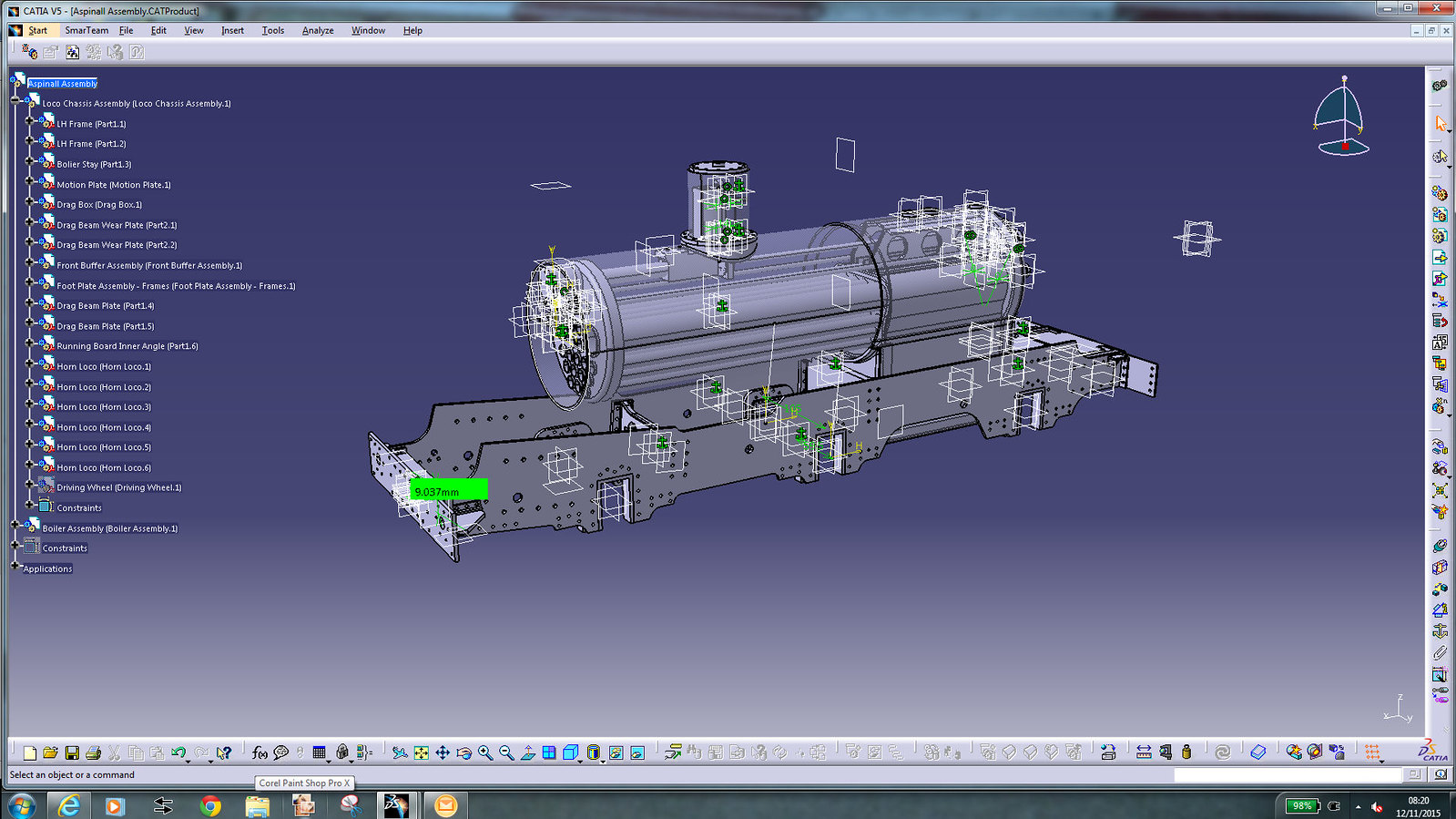

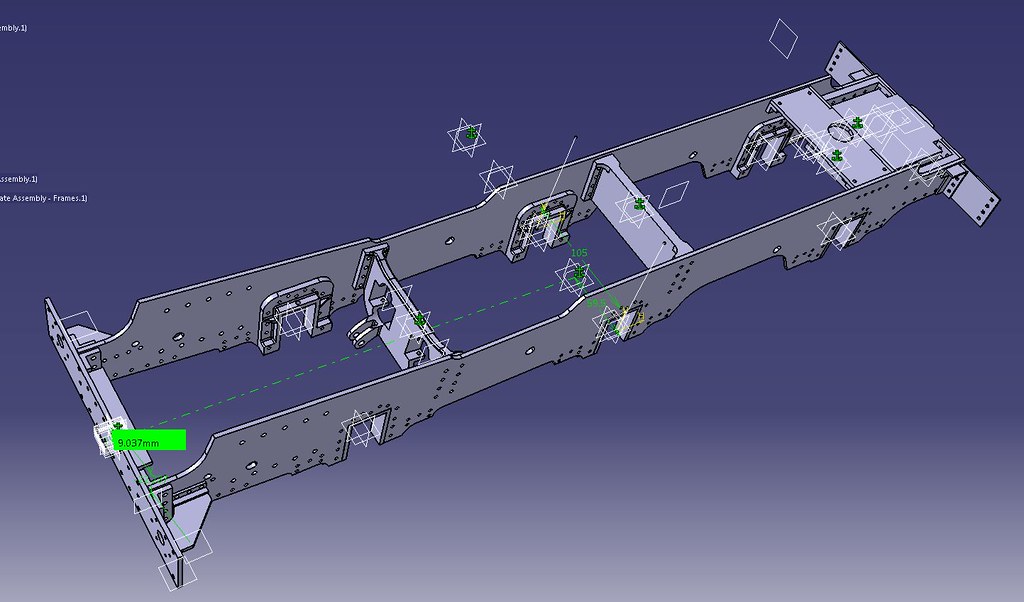

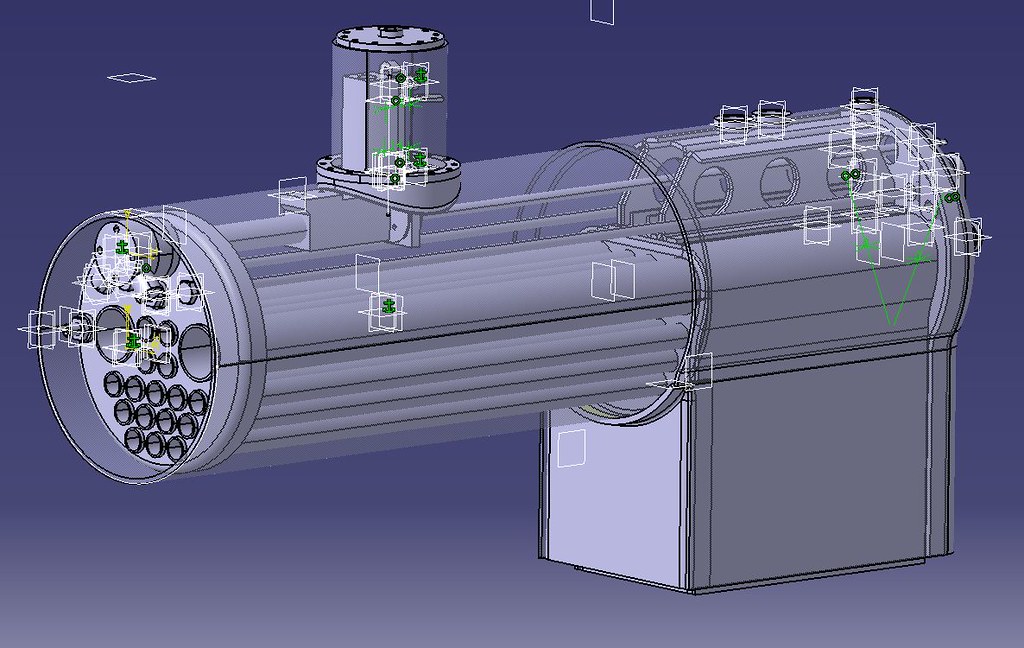

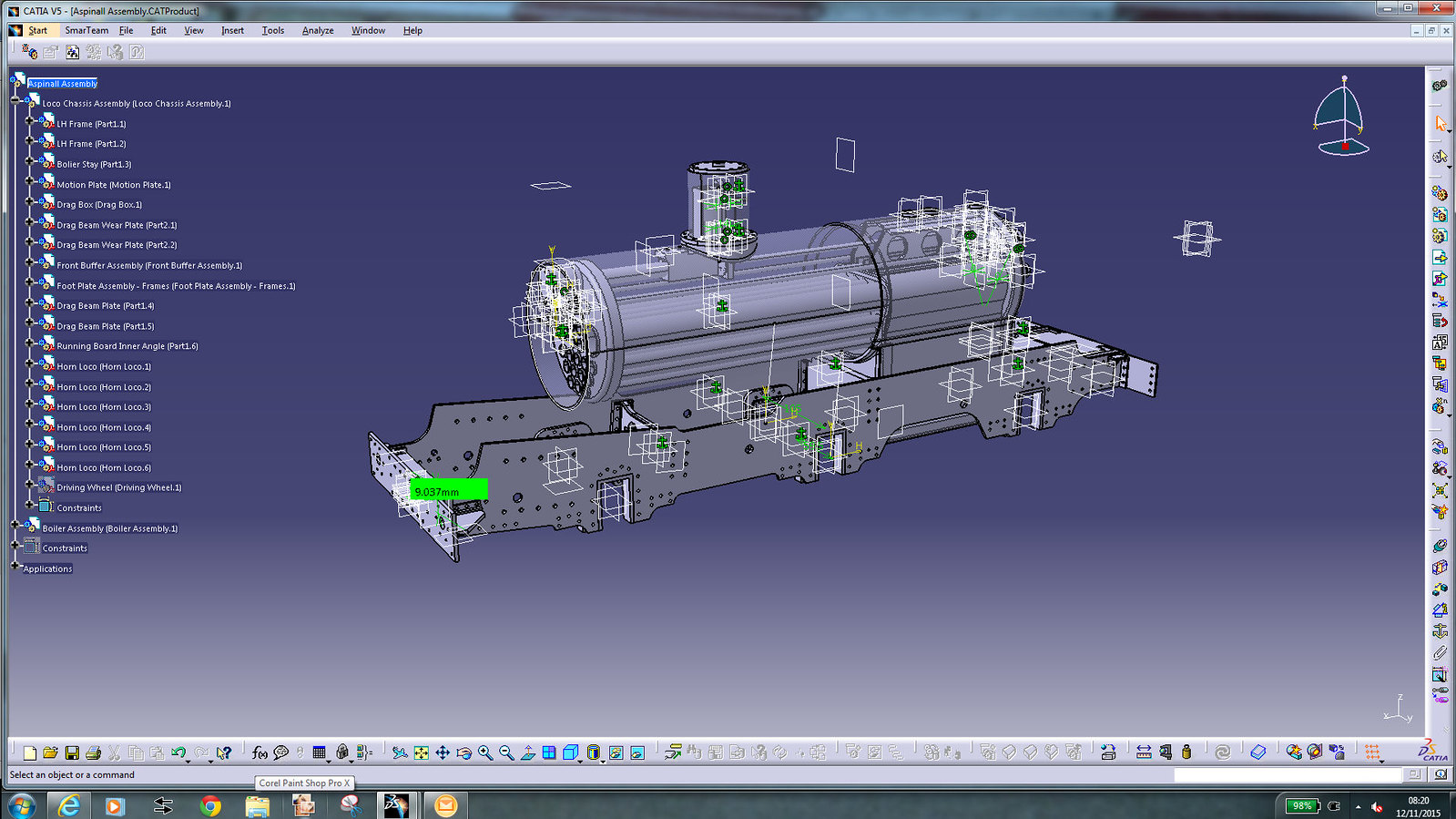

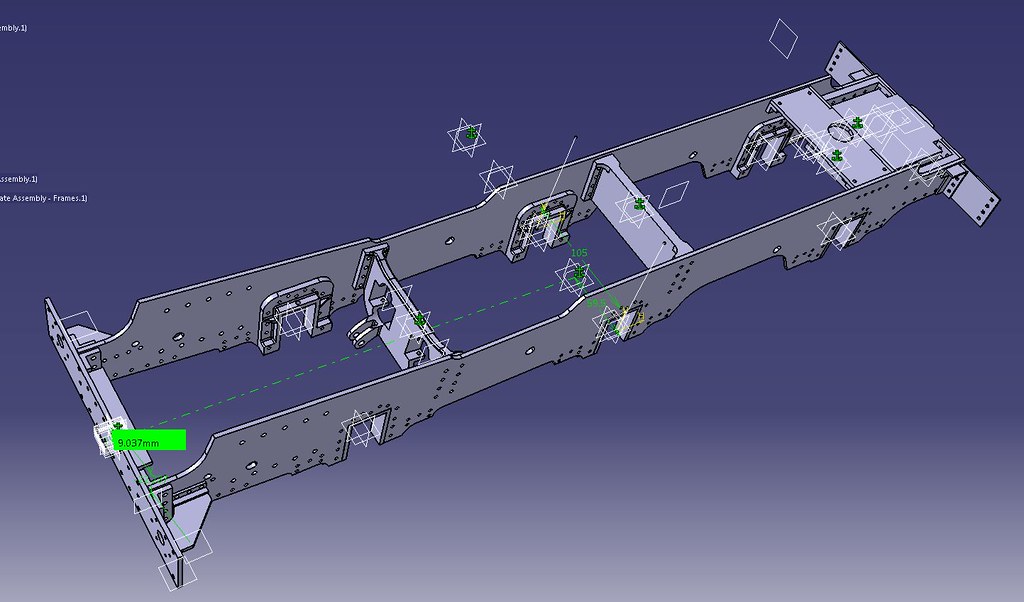

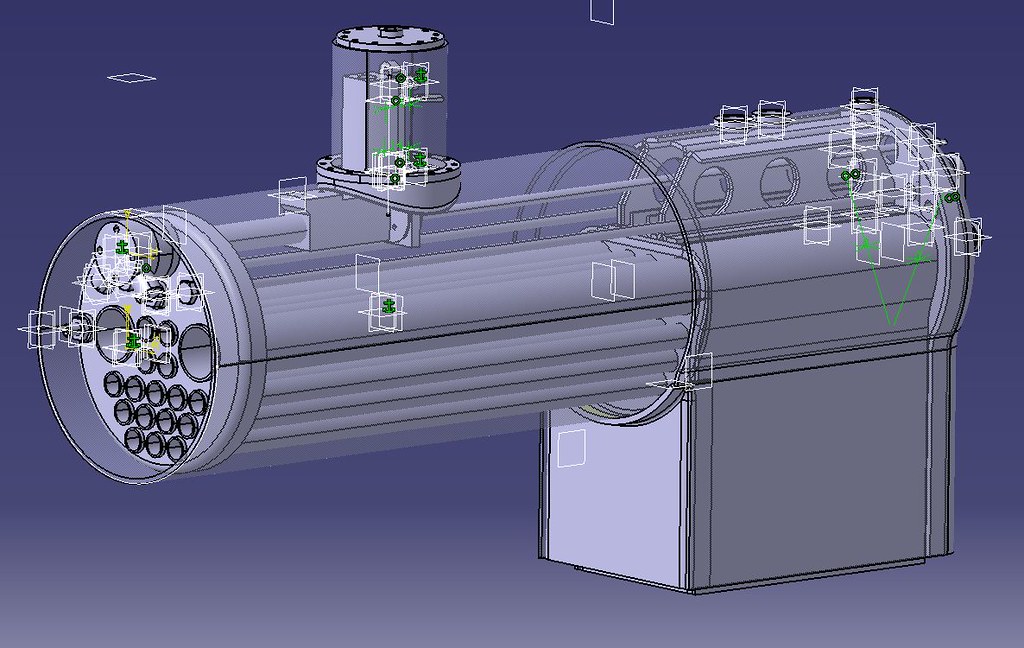

Post by kipford on Nov 12, 2015 9:00:37 GMT

After absorbing the advice given to me, I have decided to build the Don Young Aspinall class 27. Why? I have an involvement at 4mm scale in a scale 4 L and Y layout. I did all the artwork for the L and Y society for their range of 4 mm locomotive transfers (which includes the class 27). Its a good looking locomotive. You can drive it without having to compromise the cab, I like my locomotive to be reasonably accurate. So I have bought the drawings and have commenced a complete remodel in as a 3D CAD. Two reasons for this. First to sort out any missing dimensions and make sure it does all go together, second I am finding it a great way of understanding how it works. Attached are a couple of pictures of progress to date. The boiler is complete except for the backhead detail and I am now working through the chassis before dropping onto the motion. So far there have been very few problems with only the odd missing dimension. The method of dimensioning is a bit odd to say the least as there is no global datum so I have created my own on the centre driver. I am lucky enough to have access at work to a Trumpf CNC punch/laser cutter and CNC press brakes. So while I am going through the design I am looking at opportunities to where I can take advantage of these facilities.    I have bought a two year old Warco WM250 lathe. The guy who I bought it off had upgraded the headstock bearings to proper ones! added higher quality aftermarket 3 and 4 jaws chucks, quick change tool post and lots of holders, a complete set of Glanze cutting tools including parting and knurling tools. Every thing in fact to make a start. Including the stand it cost a grand which I though was a fair deal. At the weekend I bought a WM16 mill at the Warco open day. They threw in a couple a machine vice, collets a set of cutters and some clamps, so again enough to get me started. At Christmas the garage will be reworked to get it all set up properly. Any way the real reason of my post is that I have noticed that Reeves have all the castings at 15% off at the moment, so it would seem sensible to buy them now even if I do not start maching them for a while. The question I have is do I go for CI cylinders (cheaper castings) or Gunmetal? PS thanks to Midland and his wife for the hospitality at the Southampton club back in September. Dave |

|

|

|

Post by ejparrott on Nov 12, 2015 9:45:04 GMT

That's a can of worms that is, asking what cylinder material to use!

For me Iron is the only answer, as long as you keep on top of post-running dewatering and lubrication.

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on May 23, 2016 16:38:45 GMT

Things have been progressing slowly but surely, I have a lot of 4mm scale commitments that are taking time up. I have a workshop at the end of the garden but it has a suspended floor so that has been relegated to the painting and woodwork shop and the garage reworked to accept the lathe, mill, a band saw and a new bench. This machine tool lark is very addictive and I seem to find an inordinate amount of things to spend money on! The mill has had DRO’s fitted and I made some small ones from tyre depth gauges for the lathe that attach using magnets. I am starting slowly making bits and pieces to get the hang of the machines as its 40 odd years since I last twiddled any knobs. Before starting on the loco I thought I would build the driving truck as this seemed a good way to get into the swing of things without wrecking expensive castings etc. Being an idiot of course I decided to design my own truck. I wanted a truck that could be configured for both ground level and raised tracks and also something that had a bit of a prototypical look to it. The LNWR Boiler Trolley filled that brief, especially as one of its chemical wagon sisters was fitted with a body and seats to transport people around Crewe yard and this set up would provide a seat for the ground level version. So the result is the 4 wheeled wagon shown in the pictures. As I still work for a living I am very lucky and have access to Laser/Punching and CNC bending facilities. So the sheets metal parts were all designed with pre-formed holes that were laser/punched on the scrap parts jobs running through the shop floor. I know it is cheating but life is too short to not use facilities like this. As an aside we use argon as the shielding gas for our lasers which means we do not get the very hard surface on the cut edges. So the following pictures show the kit of parts and then the basic chassis pinned together. no additional holes or fettling has been used it just self jigs. Also shown is the set up for raised and ground level track. I started the machined parts yesterday so the journey begins!!!!!!!!!!! HELP: for some reason I cannot get any picture to insert from flickr or as an attachment?   ?? I have copied the link in flickr then pasted it in the URL box in insert picture but it just put a box in like this ?? I have copied the link in flickr then pasted it in the URL box in insert picture but it just put a box in like this

This is the URL address can anyone see anything wrong This is the URL address can anyone see anything wrong

www.flickr.com/photos/135583346@N06/27163292666/in/dateposted-public/Regards Dave |

|

|

|

Post by Rex Hanman on May 23, 2016 17:30:52 GMT

You can't attach pictures as the forum limit has been reached but you have managed to insert pictures ok before. I suggest you click "edit" on your previous post and see what you did differently.

Nice trolley though!

|

|