kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Feb 22, 2018 18:46:39 GMT

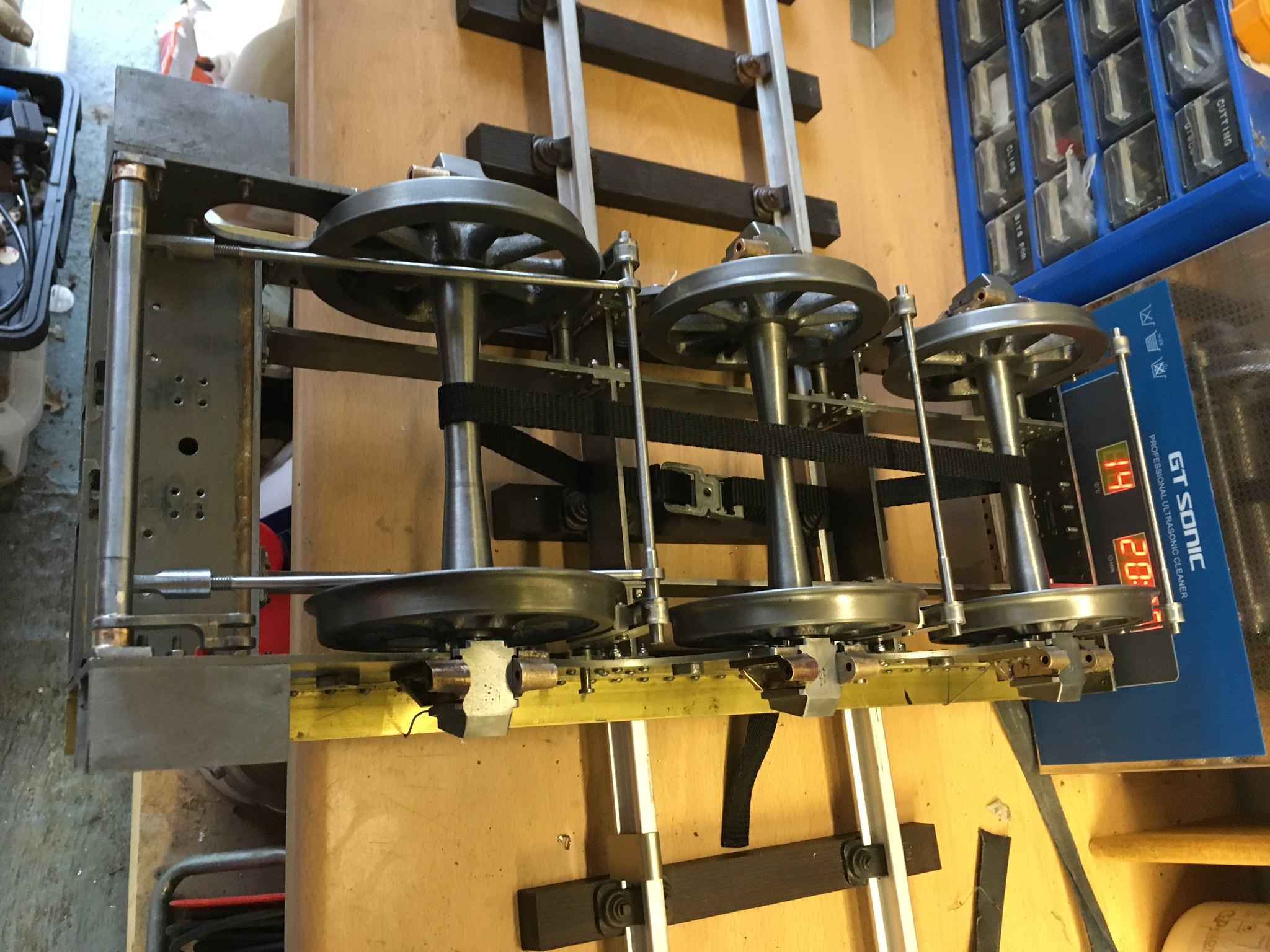

Hope to post some pictures of more work on the tender next week. I bought an oxy/propane set earlier in the week which is ace, so much nicer than using a gas torch. So I can now braze (not silver solder) all the stretchers assemblies for the tender frames and the front drag box. However to day I finished the high level track version of the driving truck. Must admit it is quite comfortable. Just need to check it out on track to make sure it rides correctly. Any way a couple of photos:  IMG_0160 IMG_0160 by Dave Smith, on Flickr  IMG_0161 IMG_0161 by Dave Smith, on Flickr Sad what!  IMG_0158 IMG_0158 by Dave Smith, on Flickr Dave |

|

|

|

Post by mr swarf on Feb 22, 2018 20:51:55 GMT

That's a very nice driving trolley. Thanks for sharing the details with us, given me some ideas for mine.

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Apr 10, 2019 21:42:15 GMT

A long while since my last post and lots of things were going on like, going back to work because they were in the sh*t and offered me a load of gold! Going to New Zealand on holiday for 5 weeks. Our first grandchild etc. I cannot do the fabulous updates that Roger, Greenglade and others do where they photograph each set up etc. I find by the time I remember to do anything, I am miles down the road, so updates will be a case of this is what it now looks like. I must admit was also a bit concerned the quality may not be quite as good as some! Anyway here are we, still on the tender of course: A word on the axles boxes: These were supposed to be made from bronze castings, but the castings were crap, being too small and not cleaning up when machined. So I cut my losses, binned them and redesigned them in steel using needle roller bearings. I then wrote off the first steel set due to me assuming a slot drill will cut to the size it is supposed to be! The machine shop at the Mid Hants Railway where I volunteer put me right on this one and advised a suitable machining technique and sequence. The photos below show the squared off blocks and the finished items. I must admit I am quite pleased with the result and learnt a hell of a lot about using a mill. I have made about 90% of the tender now, with only the last parts of the brake system, tender springs and the water valves to go. Then it needs undercoating and assembly. I will top coat the tender body when the loco is finished. A deviation from Don’s design is that apart from the coping and the tool locker boxes, the tender body is all steel. Reason for this is that I got it laser cut for £0 at work, rather than about £200 in brass from Model Engineers Laser, no brainer, you can protect steel quite adequately. Also like Roger I am using all metric threaded fasteners. So some photos: Steel axle boxes.  20180811_163819446_iOS 20180811_163819446_iOS by Dave Smith, on Flickr Boxes of bits  IMG_0727 IMG_0727 by Dave Smith, on Flickr On axles for first time  IMG_0872 IMG_0872 by Dave Smith, on Flickr  IMG_0873 IMG_0873 by Dave Smith, on Flickr  IMG_0741 IMG_0741 by Dave Smith, on Flickr First stages of brake rigging.  IMG_0881 IMG_0881 by Dave Smith, on Flickr  IMG_0878 IMG_0878 by Dave Smith, on Flickr  IMG_0876 IMG_0876 by Dave Smith, on Flickr  IMG_0875 IMG_0875 by Dave Smith, on Flickr Hope they are of interest Dave |

|

Midland

Elder Statesman

Posts: 1,875

|

Post by Midland on Apr 11, 2019 7:44:02 GMT

Beautiful and clean! Makes my learning project from 20 years ago look a bit rubbish!! I hope the paint will cover a multitude of sins!!!!

Cheers David

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Apr 11, 2019 9:01:45 GMT

David

Been there got the tea shirt, it is amazing what a bit of filler can do. I volunteer at the mid hants on Wednesdays in the loco shed. S15 No 506 is starting to get its final paint job. Having seen the lumps bumps crevices etc in the boiler cladding, before they started and the amount of filler they applied yesterday when I was walking by, you have no worries.

Dave

|

|

|

|

Post by Deleted on Apr 11, 2019 9:37:30 GMT

Excellent Dave, love the detail on the axle boxes...As it's one of Don's I bet they are fairly prototypical in shape accepted you have added needle bearings...they look the business sir...

Regards

Pete

|

|

Midland

Elder Statesman

Posts: 1,875

|

Post by Midland on Apr 11, 2019 9:43:38 GMT

Pete

Twenty years ago I hacked those axle boxes out of solid with a file and a fobco drill. Even so they do not look that bad! Then I discovered milling and it has been downhill ever since!

D

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Apr 28, 2019 9:07:53 GMT

I recently joined Fareham and District Society of Model Engineers, they seem a very nice bunch, very welcoming. So I took the opportunity last Thursday to try out the driving truck on the raised track. Very pleased it runs well and appears very stable. The only issue is I need to space out the foot rests another 12mm or so each side to clear errant sleepers. Also had a good chat with the boilers inspectors about the boiler build, they suggested some improvements to Don's design which I am incorporating. One of them has previously built one of the boilers for someone else, so we experience available.  IMG_0908 IMG_0908 by Dave Smith, on Flickr Dave |

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,988

|

Post by JonL on Apr 28, 2019 11:02:12 GMT

Thats a very tidy driving truck. I've just got some bogies from a friend, hopefully it's the start of a nice truck for mine (nothing like jumping the gun!).

Can I ask which Oxy/Propane set you went for? Now you've had it a little while would you recommend the one you bought? I'm just about to make the pounce myself. Sorry to derail the thread.

Thanks,

Jon.

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Apr 28, 2019 11:37:16 GMT

Nobby Having used it for about a year would recommend an oxy/propane set up in addition to ordinary propane, but I use both. To be honest I cannot remember who it came from but it was on Ebay and around £150. They all seem much of a muchness. What I do use though is the Welderworkshop propane no 3 nozzle in lieu of the standard oxy/acetelene ones as shown in the picture, they are much easier to control. Note it will still end up costing around £300 to set up though, once you have paid the for the oxygen and propane bottles. What bumps it up is the one off fees for the bottles.  Capture1 Capture1 by Dave Smith, on Flickr Dave |

|

JonL

Elder Statesman

WWSME (Wiltshire)

WWSME (Wiltshire)

Posts: 2,988

|

Post by JonL on Apr 28, 2019 14:49:01 GMT

Ok, might have to wait for a bit then! Thanks for the info.

|

|

|

|

Post by andyhigham on Apr 29, 2019 14:20:05 GMT

If you are ever up this end of the country, the sole surviving class 27 is regularly running on the East Lancs railway

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Apr 29, 2019 18:27:09 GMT

Andy

Thanks yes I know, not had a chance to visit the East Lancs yet. HOWEVER, I am up in Preston at the end of May helping out on a project for the Mid Hants Railway, if we get time I may swing by on the way home and have a look at it.

Dave

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Jun 21, 2019 21:52:59 GMT

|

|

Midland

Elder Statesman

Posts: 1,875

|

Post by Midland on Jun 22, 2019 8:53:22 GMT

Dave

All Aspinal builders I have spoken with say the tender is worse than the loco so down hill now on! Lovely job on the tender!

D

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Jul 6, 2019 9:23:06 GMT

Question for the forum. DY specifies bronze for the front and rear cylinder covers. With bronze being very expensive I was thinking of machining the covers in either steel or Stainless with the rear cover bushed for the piston rod. I think the potential long term problems are far outweighed by the cost saving, what the consensus?

|

|

|

|

Post by Deleted on Jul 6, 2019 10:08:21 GMT

Question for the forum. DY specifies bronze for the front and rear cylinder covers. With bronze being very expensive I was thinking of machining the covers in either steel or Stainless with the rear cover bushed for the piston rod. I think the potential long term problems are far outweighed by the cost saving, what the consensus? I would say steel or stainless should be fine, it's only a cover to seal the cylinder, I can't see any problem with using another material. Pete |

|

|

|

Post by David on Jul 6, 2019 22:03:35 GMT

Cast iron is extremely common for cylinder covers. Do rates of expansion matter much on cylinder covers?

|

|

|

|

Post by thumpersdad on Jul 8, 2019 5:57:08 GMT

Have you considered the possibility of galvanic corrosion between dissimilar metals in a warm moist environment?

Eric

|

|

timo

E-xcellent poster

Completing 3 1/2 Rainhill .Building 5" Railmotor and waiting to start 3 1/2" King

Completing 3 1/2 Rainhill .Building 5" Railmotor and waiting to start 3 1/2" King

Posts: 234

|

Post by timo on Jul 8, 2019 7:58:56 GMT

Cast iron is extremely common for cylinder covers. Do rates of expansion matter much on cylinder covers? David,

I guess it depends how much of an experiment you want. If you have three different materials, cylinder, covers and studs with quite different coefficients of expansion then something will have to give. Will it matter? I don't know but if you use gunmetal cylinders and covers with stainless studs (stainless has a similar coefficent to gunmetal I believe) then you won't have problems. I do know you can get internal rust / corrosion problems with cast iron cylinders and covers and have seen some ingenious solutions to lubricating same after a run and during storage - special screw in plugs on the cylinder covers so that oil can be squirted in for example.

Tim

|

|