kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Jul 8, 2019 8:11:21 GMT

Eric

Yes, corrosion is my only concern, as mechanically there are no issues. The potential difference between Bronze/SS or Bronze/Mild Steel is about half that of Aluminium/SS which you have to be very careful of. However I would only expect problems with long term continuous exposure, which the cylinders are not going to be subject to. I think I may have answered my own question.

Dave

|

|

|

|

Post by David on Jul 9, 2019 0:21:03 GMT

I do know you can get internal rust / corrosion problems with cast iron cylinders and covers and have seen some ingenious solutions to lubricating same after a run and during storage - special screw in plugs on the cylinder covers so that oil can be squirted in for example. My loco has cast iron cylinders and cylinder covers and has occasionally seized up between runs when I didn't get enough oil into them. But it's always come back fine after a tap on the big end of the con-rod with a soft hammer and piece of wood. I've just drilled and tapped the front cylinder covers so I can get more oil into them after a run. I think rusting is a minor problem. Hardly anyone down here uses gunmetal cylinders. |

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Jul 9, 2019 12:17:11 GMT

DOH!!!!!!! You know some days you wonder if your mind is going. I bought all the castings about 2 years ago, suddenly remembered they include the front and rear covers, so no problem. What is interesting is that the price of the casting has increased by around 30% since purchasing them.

Dave

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Mar 25, 2020 22:59:44 GMT

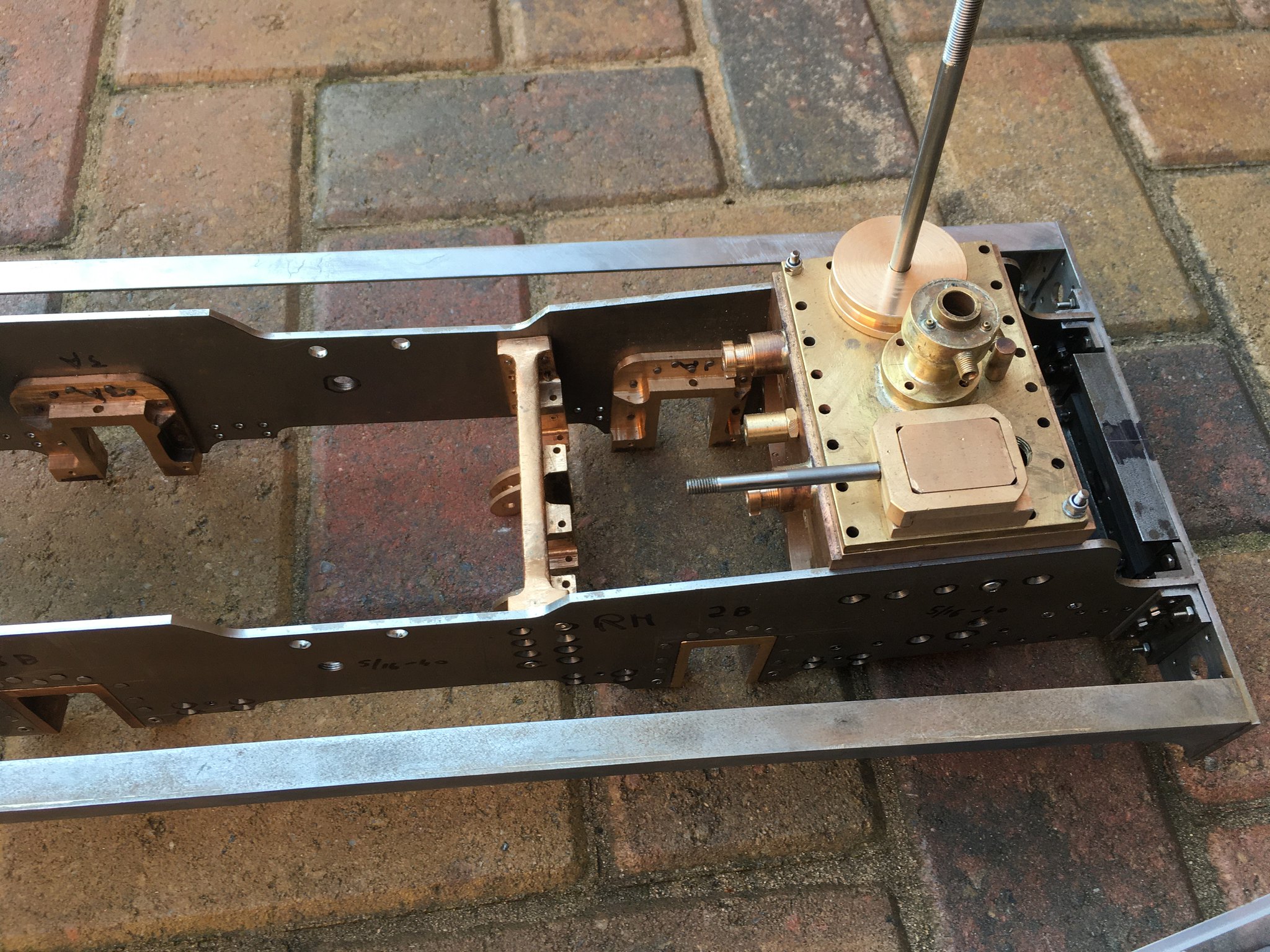

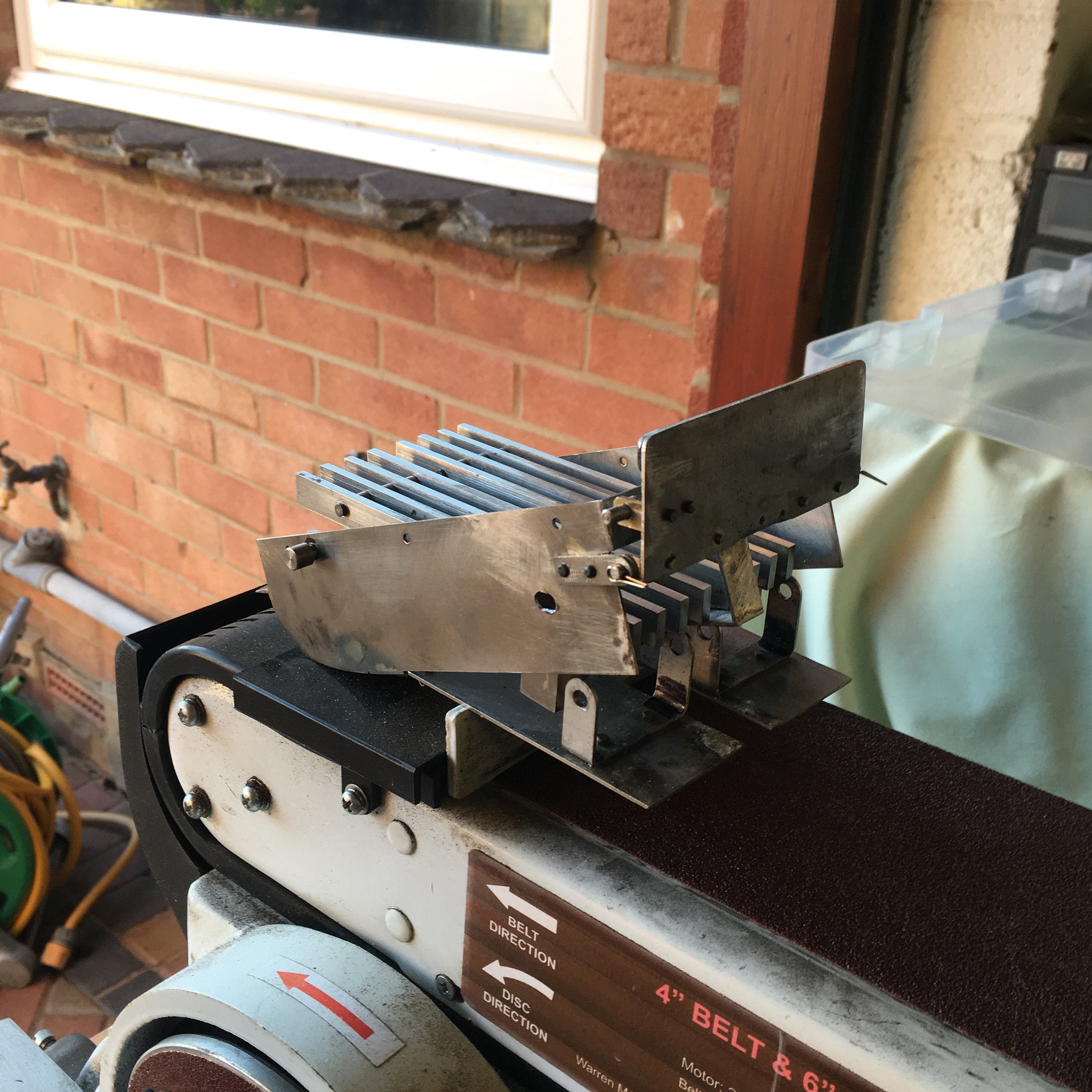

A stop and start time on the Aspinall since my last post. Other distractions have been haemorrhaging the time available to work on it. First after an offer I could not refuse, I went back to work for 7 weeks which involved living away during the week (very lucarative as I got paid travelling time as well) so I lost nearly two months there. Since Xmas I have had 6 weekends away at model railway exhibitions with my own 4mm scale Brighton East layout and the SHMRC's LNWR/GWR Hope-under-Dinmore. I was also finishing the production standard of an LNWR shunting engine and building the first prototype of the LNWR crane tank 4mm scale kits which I have been working on for the last couple of years. Finally I have been re-engineering the centre cylinder casting of unrebuilt Bullied Swanage for the Mid Hants Railway, so the Aspinall has taken a bit of a back seat. Oh and like I am also finishing a major piece of DIY. But am now starting to get going again and with social distancing I am going to have a bit more time to spare! The first photo shows the two LNWR girls on Hope at the Leamington exhibition, then the bits I have finished on the loco since completing the tender. Loco frames with horns fitted but not final machined. Drag box, boiler stay, motion plate, the complete cylinder assembly including the blast pipe, front foot steps, rear foot steps/valence and the ashpan/grate.  IMG_1652 IMG_1652 by Dave Smith, on Flickr  IMG_1688 IMG_1688 by Dave Smith, on Flickr  IMG_1691 IMG_1691 by Dave Smith, on Flickr The ashan/grate was finished last week. Don Youngs design has a fixed gate with the only access either via the smoke box and the damper flap. I was not happy with this and wanted to try and get access to empty the ashpan from underneath the loco. However the centre pull brakes prevent the ashpan being a simple drop down affair. I did not want to change or delete the brakes so came up with a compromise design which has two dropdown doors and a moving grate. By drop the doors and the grate there should be sufficient room to remove any detritus from the ashpan and grate. The next couple of photos show the result although It is not fully cleaned up yet.Today I started work on the axle boxes and the photos show progress so far. Being a split box design , I was very nervous about getting the fit between the two parts correct. It seems myself and my mill can work to the required accuracy.  IMG_1697 IMG_1697 by Dave Smith, on Flickr  IMG_1700 IMG_1700 by Dave Smith, on Flickr  IMG_1703 IMG_1703 by Dave Smith, on Flickr Dave |

|

|

|

Post by coniston on Mar 26, 2020 21:02:36 GMT

Welcome back Dave, a lot of great work there.

Chris D

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Mar 26, 2020 22:52:44 GMT

Thanks Chris. With the increased modelling time now available I hope to make some good progress. What about your A3 are we going to see progress on that now? Todays tasks were to 3D print some Armco barriers in 4mm scale for my son and take the flash off the castings for the driving wheels (in between the obligatory exercise and a bit more decorating). I am waiting to see if M2 screws I ordered turn up before doing any more work on the axle boxes. I want to use the screws to hold the split axle boxes together rather than pins.

Dave

|

|

|

|

Post by coniston on Mar 27, 2020 20:39:16 GMT

Thanks Chris. With the increased modelling time now available I hope to make some good progress. What about your A3 are we going to see progress on that now? Todays tasks were to 3D print some Armco barriers in 4mm scale for my son and take the flash off the castings for the driving wheels (in between the obligatory exercise and a bit more decorating). I am waiting to see if M2 screws I ordered turn up before doing any more work on the axle boxes. I want to use the screws to hold the split axle boxes together rather than pins. Dave Currently adding it to 'What I've done today' post but maybe I should create a new one to keep it all together? Chris D |

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Oct 24, 2020 16:30:33 GMT

A lot has happened since my last post in March. Basically I now have a rolling chassis with the cylinders and slide bars complete, plus some bits plate work to give some light relief. The coupling rods were fitted this afternoon after three attempts at the bushes for the trailing rods. The rods need draw filing and the oil ways drilled but at least I know it all turns over ok. By the way I am never building a loco with 4 slide bars per cylinder again! About 50% of the valve gear is done and I hope to have it running on air in the early part of the new year. Then it’s the boiler. Anyway photos showing progress to date.  IMG_2270 IMG_2270 by Dave Smith, on Flickr  IMG_2269 IMG_2269 by Dave Smith, on Flickr  IMG_2271 IMG_2271 by Dave Smith, on Flickr  IMG_2272 IMG_2272 by Dave Smith, on Flickr  IMG_2373 IMG_2373 by Dave Smith, on Flickr Regards Dave |

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Nov 9, 2020 10:33:25 GMT

Bit more progress. I have finished mechanically the connecting rods. The bolts have been trimmed since the photos were taken and they need a final polish up, but I wanted to see if they fitted ok. good news is they do and the piston movement appears to be within 2 or 3 thou of where it should be both in the forward and backward positions. The whole assembly is a bit stiff at the moment, but I would prefer to either bed it in or just tickle the odd part than have it like a ROD from day one. I am now pressing on with remaining valve gear parts, which should be finished by the end of the week. Dave  IMG_2391 IMG_2391 by Dave Smith, on Flickr  IMG_2394 IMG_2394 by Dave Smith, on Flickr |

|

|

|

Post by coniston on Nov 9, 2020 20:55:21 GMT

Looks pretty damn good to me Dave

Chris D

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Nov 12, 2020 20:20:32 GMT

Seminal moment today, did a first fit on all the valve gear. Ok its not timed or all the proper pins in yet, but it all fits and appears to be in the correct place. first two photos are of the remaining valve gear parts and the slide shaft with the vibrating links fitted. Hopefully running on air by Xmas. PS still a lot of final polishing to do though. Dave  IMG_2409 IMG_2409 by Dave Smith, on Flickr  IMG_2397 IMG_2397 by Dave Smith, on Flickr  IMG_2410 IMG_2410 by Dave Smith, on Flickr |

|

|

|

Post by coniston on Nov 12, 2020 21:31:04 GMT

A moment to savour Dave

Chris D

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Nov 20, 2020 14:00:59 GMT

Made up and test fitted all the pins to hold the valve gear together. As I previously said, it was all very tight. The main culprit was the cross heads in the slide bars having a couple of tight spots. I did not want to take it apart again and re-shim, remember its 4 bars per piston and was real struggle to get them all this far and we were now probably talking about less than a thou error and I was not confident I would get it any better. So I used a trick which I have used very successfully in 4mm scale. Just run to knock off the high spots! So I made up an adaptor to fit in the end of the drill the would engage on the wheel spokes. Then removed all the valve gear and side rods put loads of oil every where, then gave it a couple of minutes running every now and then until it loosened off. This normally take about 20 - 30 mins in 4mm and this proved the same for the Aspinall. Quick video. The hunting noise is where the drill is not running on centre. Anyway pleased with result. I am now taking the laser and machining marks off the rods. 'O' rings turned up from Eastern Seals yesterday (less than 24 hours from order to delivery) so we are getting very close to running of air. Dave Running in |

|

|

|

Post by Deleted on Nov 20, 2020 16:09:44 GMT

Love the video Dave, she turns over very nicely...

Pete

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Nov 20, 2020 16:42:35 GMT

Pete

Not counting my chickens yet but it does feel good both physically and mentally. I was a bit concerned about it all being to far out of true. But it seems I was not that far out. Got to finish polishing the rods, lap the slide valves, pop some o rings on various bits, put the valve gear back on, then stand back and pray it all works. However I think a nice bottle of red tonight to celebrate that at least the wheels and pistons turn over:P .

Dave

|

|

|

|

Post by Deleted on Nov 20, 2020 17:11:57 GMT

You deserve a good drink, Dave, she runs great. i'm sure that we all question our own work, I do it all the time and still have no idea whether 4472 will ever run... I guess I still have a few years to go before finding that out? Keep up the good work sir, she's a credit to your hard work.

Pete

|

|

|

|

Post by coniston on Nov 20, 2020 20:56:27 GMT

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Nov 20, 2020 22:50:49 GMT

Chris

Had not really thought about different laps. I was going to use fine valve lap and finish with TCut (I did the Joy slides using only TCut) as I have some. But the stuff in your link looks good so I have just ordered some.

Dave

|

|

|

|

Post by andyhigham on Nov 20, 2020 22:57:18 GMT

At some point you should venture up north. Visit the East Lancs railway and see the only surviving class 27 loco and maybe ride behind it

|

|

kipford

Statesman

Building a Don Young 5" Gauge Aspinall Class 27

Building a Don Young 5" Gauge Aspinall Class 27

Posts: 575

|

Post by kipford on Nov 21, 2020 9:24:21 GMT

Andy

Agreed, that is a trip I want to do sometime.

Dave

|

|