|

|

Post by runner42 on Jun 22, 2018 7:53:27 GMT

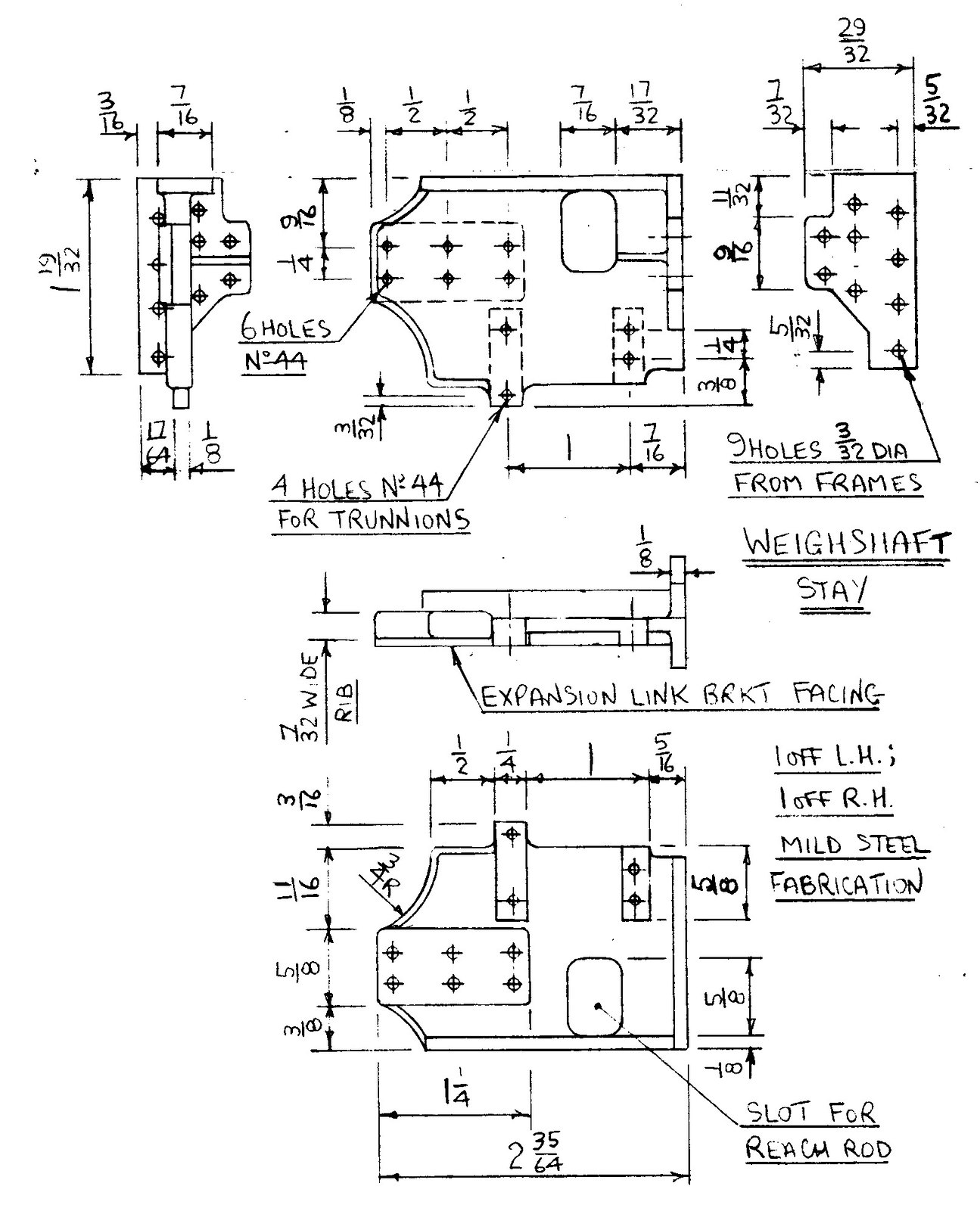

I have started making Don Young's Black 5. I don't know if I have bitten off more than I can chew. I have the set of drawings but no published words and music, so I am heavily reliant on understanding the drawings. The drawings are very busy cramming a lot of information on each sheet probably needed to have twice as many sheets than is provided and using them at the coal face is worse than trying to read those old broad sheet newspapers. I am getting the mainframes laser cut, whilst waiting for them I decided to start on something relatively simple such as the expansion link assembly including the expansion link bracket. The expansion link bracket consists of 5 pieces that I assume needs to be silver soldered together. The part of the drawing for this is not dog b*lls obvious in how each part is produced but after much head scratching I have come up with what I think is required. What I would like some assistance on is how I would hold the pieces during the silver soldering operation. The critical point is getting a right angle between the two major parts. I have scanned the relevant item to provide visibility on the requirements. An aside the drawing shows a hole to enable the reach rod to pass through the bracket for both the LH and RH. It is only required for the LH I assume. Brian  Expansion link bracket Expansion link bracket by Brian Leach, on Flickr |

|

44767

Statesman

Posts: 538

|

Post by 44767 on Jun 22, 2018 11:05:03 GMT

Hi Brian,

There are a few chaps on here who are building Don Young's Black 5, including me. You should be able to sort out any issue you may have.

Is that a particularly old set of his drawings? The set I have, although drawn by hand, has been drawn much more neatly with stenciled lettering etc. I'm not saying yours is wrong, it's just that my set dates back to the early 80's and I wonder just how long you have had yours.

As far as fabrication goes, I cut my teeth on this model; I knew nothing about engineering before I bought a set of these drawings and a lathe. So everything was an exercise in fabrication and machining. I learned early on that, as in full size, make your fabrications to a size that will allow it to be machined to the finished sizes on the drawing. Do not expect to fabricate anything square enough and to size that it does not need machining. Therefore, allow a little extra thickness on the flanges and faces which will all be brought to size by machining. Your fabrications then need not be quite as accurate as you fear.

I used a lot of 1.6mm pins to hold parts in place while they were soldered but the method is up to you. Slots and tabs is another good method which gets parts nicely aligned. You'll get used to having to design the fabrication before you can machine it to the drawing. Having said that, there are a few castings done by third parties which would suit this model.

I hope you enjoy making the model as it's a cracking model when finished!

Mike

|

|

Lisa

Statesman

Posts: 806

|

Post by Lisa on Jun 22, 2018 12:04:20 GMT

Re: dodgy drawings, did you get them from ej winter Brian? Some of their drawings are pretty ancient.

|

|

|

|

Post by Deleted on Jun 22, 2018 12:45:35 GMT

|

|

oldnorton

Statesman

5" gauge LMS enthusiast

5" gauge LMS enthusiast

Posts: 721

|

Post by oldnorton on Jun 22, 2018 19:32:23 GMT

Hi Brian

I also am building DY's Black 5. But it has come to a halt for a year, no problem I will be back on it again very soon.

Your drawings look early or pre-editions or copies? You can get a nice set from A J Reeves (webshop) and these are the ones that Don refers to in his LLAS write up. Well worth buying.

I have found the drawings a delight to work from. Maybe one or two minor errors but nothing you cannot spot at the time. The nice thing is that Don drew them to closely match the works drawings, and he should know as he worked in the sheds on Black 5s.

Mike fron NZ (reply above) is an expert in many aspects and I would merely class myself as a 'potential helpful' who will be pleased to respond to any question from you.

Don's extracts from LLAS I do have on file and if you PM me I am sure that I can assist in some way.

ME laser (Malcolm High) does good steel work and some nice laser cut brass for the cabs and tenders. He supplies to others so best to go direct to the source.

Norm.

|

|

44767

Statesman

Posts: 538

|

Post by 44767 on Jun 23, 2018 1:53:07 GMT

An aside the drawing shows a hole to enable the reach rod to pass through the bracket for both the LH and RH. It is only required for the LH I assume. Brian I think you're right that the hole only needs to be in the LH bracket. However. I have it on both sides of my model. I think I took it quite literally that it was LH and RH (i.e. mirror parts) as it did not state that the hole for the reach rod was only on the LH bracket. I'll have to find photos of full size to check but you may find that on the RH side some pipework may have been routed through the hole. |

|

|

|

Post by runner42 on Jun 23, 2018 5:58:23 GMT

Thanks for the replies.

Lisa the drawings are second hand and the pedigree is unknown, but they appear to be complete and accurate so I will use them with confidence, unless and until they prove otherwise. I shall use EJ Winter for the castings for wheels, cylinders and any other items that appear to be a close match to what Don Young has specified.

Pete thanks for the links particularly the model engineers laser, the UK appears to be well served for suppliers of specialized parts.

Norm thanks for the kind offer of assistance, I'll PM you.

Mike thanks for the encouraging words, yes Don Young's Black 5 is a cracking locomotive. I had the opportunity to drive one recently which inspired me to start this project. I have completed the pieces that make up the brackets and I'll use your recommendation to pin them, they have so much more detail than LBSC's Doris.

A question that has arisen is for the 9 x 3/32" dia holes in the part that bolts to the frames, what type of fastener is recommended as I suspect that the head of the fastener needs to be small and a hex drive to prevent fouling with the main horizontal member.

Brian

|

|

44767

Statesman

Posts: 538

|

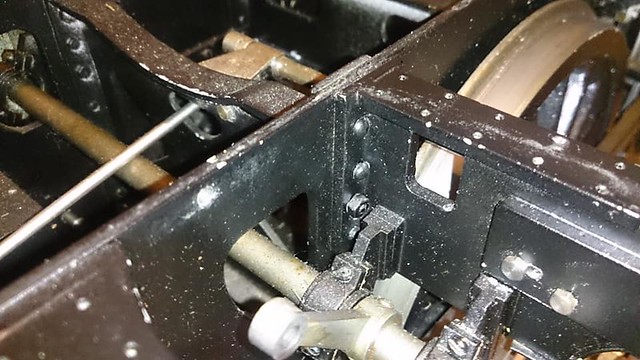

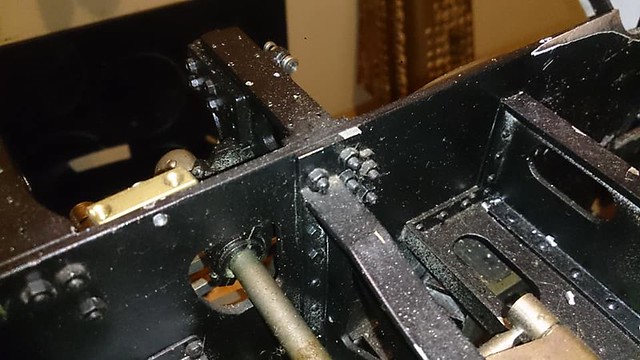

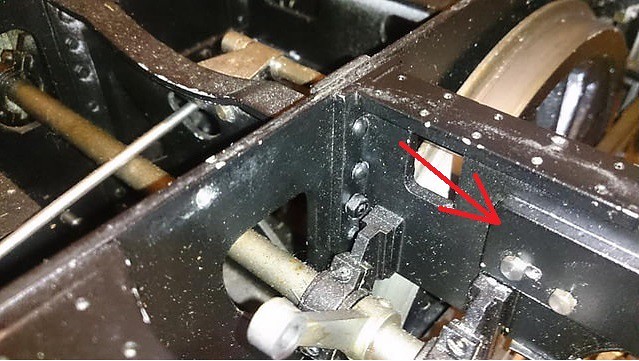

Post by 44767 on Jun 23, 2018 6:44:21 GMT

Mike thanks for the encouraging words, yes Don Young's Black 5 is a cracking locomotive. I had the opportunity to drive one recently which inspired me to start this project. I have completed the pieces that make up the brackets and I'll use your recommendation to pin them, they have so much more detail than LBSC's Doris. A question that has arisen is for the 9 x 3/32" dia holes in the part that bolts to the frames, what type of fastener is recommended as I suspect that the head of the fastener needs to be small and a hex drive to prevent fouling with the main horizontal member. Brian Here's a photo of mine which I have just taken. Excuse the dusty appearance, please!)  You can see that I must have turned the hex off the screws to make them look like rivets from the outside of the frame. Note the one you can't get in from the outside because of the pad for the weighshaft bearing bracket!  The nuts are on the inside but note that these bolts also go through the stay between the frames. I'm not sure what your machining skills are like but having done a lot of machine building I realise that best practice is not to use bolts to locate parts; they should be in clearance holes. So some other means of locating the part is necessary. I would plan the machining of the parts to include two dowel holes (say 2mm), machined relative to the holes on the drawing (in line with and between other holes is fine) and place corresponding holes in the frame and the stay, in this case. Then alignment will be automatic. I hope this helps a bit. As far as sizes go for the screws: I now use metric fastenings. There is an German firm which makes fastenings with scale size heads using standard metric threads. Their range is huge with hex head, round head, Allen head, countersunk etc. in brass, steel, stainless steel, some blackened steel etc. and sizes right down to M0.6 with 1mm A/F hex heads. They also have a range of spanners and nut runners which are designed to fit these and still clear the flanges you talk of. I'll get details later, if you're interested. Cheers, Mike |

|

|

|

Post by runner42 on Jun 23, 2018 7:32:58 GMT

Hi Mike, thanks for the photo, I can see now that there is an extra pad indicated in the photo that I have missed, although now obvious I could not see that it was there on the facing diagram, which was a little confusing to me. Brian  Expansion link bracket photo Expansion link bracket photo by Brian Leach, on Flickr |

|

44767

Statesman

Posts: 538

|

Post by 44767 on Jun 23, 2018 7:45:43 GMT

Brian,

You may have noticed mine does not have the holes for the expansion link bracket as I'm building 44767, the only Black 5 to have Stephenson's Link motion.

|

|

|

|

Post by ettingtonliam on Jun 23, 2018 10:08:50 GMT

[quote author=" 44767" source="/post/160965/thread" timestamp="15297362 As far as sizes go for the screws: I now use metric fastenings. There is an German firm which makes fastenings with scale size heads using standard metric threads. Their range is huge with hex head, round head, Allen head, countersunk etc. in brass, steel, stainless steel, some blackened steel etc. and sizes right down to M0.6 with 1mm A/F hex heads. They also have a range of spanners and nut runners which are designed to fit these and still clear the flanges you talk of. I'll get details later, if you're interested. Cheers, Mike[/quote] This German firm doesn't do square head nuts and bolts for fasteners in the 2 -4 mm range does it? Richard |

|

44767

Statesman

Posts: 538

|

Post by 44767 on Jun 23, 2018 10:41:43 GMT

This German firm doesn't do square head nuts and bolts for fasteners in the 2 -4 mm range does it? Richard I've just had a look Richard. I'm afraid they don't. But have a look here to see their range. You'll probably need to get Mr Google to translate it for you! |

|

Lisa

Statesman

Posts: 806

|

Post by Lisa on Jun 23, 2018 10:46:21 GMT

They do have square nuts for M2 and M3, go to "Muttern -Stopp/-Hut/-Spezial" (Nuts -Stop/-Hat/-Special), then "Vierkantmuttern" (Square Nuts). Not bolts though, but they do make everything themselves, so you can always ask.

|

|

44767

Statesman

Posts: 538

|

Post by 44767 on Jun 23, 2018 11:09:49 GMT

Oh, yes, sorry, I did see the nuts but I thought you were looking for bolts. I have asked them to make special bolts but they really only have time to do their own parts. Depending on quantities you could try Polly Models. They have a lovely new Star sliding head Swiss auto and recently made 2500 of these for me. They are M2.5 with a g6 tolerance shank and 60 degree taper.  They are for holding on the horn blocks on the class 3's   Cheers, Mike |

|

|

|

Post by simplyloco on Jun 23, 2018 12:04:16 GMT

They do have square nuts for M2 and M3, go to "Muttern -Stopp/-Hut/-Spezial" (Nuts -Stop/-Hat/-Special), then "Vierkantmuttern" (Square Nuts). Not bolts though, but they do make everything themselves, so you can always ask. When Richard asked about square headed nuts I thought that he was just having a go at the Germans!  |

|

|

|

Post by ettingtonliam on Jun 23, 2018 12:20:51 GMT

Ho Ho. Having some German relations, I wouldn't dare do that!

|

|

dscott

Elder Statesman

Posts: 2,440

|

Post by dscott on Jun 23, 2018 22:29:29 GMT

I splashed out on a pair of brackets from Model Engineers Laser last Midlands show!

When I say pair 4 sets as I intend building 2 with some help from a completed tender

and a lifetime of machining!!!

Had a superb day driving a friends Sweet Pea round the Reading Track... Such a relaxing

locomotive.

Took my Black Five Boiler for a show to the Young Engineers. Quite a lump.

The expansion brackets do need that lovely beading soldered round the outside to

make them look superb!!

Who said that Life was easy!!

David and Lily.

|

|

jma1009

Elder Statesman

Posts: 5,919

|

Post by jma1009 on Jun 23, 2018 23:43:18 GMT

Hi Brian,

It is nice to see Don Young's handwriting and original pen work on his drawings. Those of us with the IOW O2 5"g 'Fishbourne' drawings were never retraced apart from the GA, and are also in Don's own hand.

I have a folder of correspondence with Don somewhere. Don would invariably type a letter, then add lots of penned additions!

At 'Bardonela', Adgestone, in the 1980s and 1990s Don had a large photocopier for copying his original drawings such as 'Fishbourne' and the Black 5 Stephenson valve gear details, and the retraced masters; pretty much everything else having been retraced.

Your drawings must be very old and of interesting origin, and I would strongly recommend you purchase a set of updated drawings as retraced. Don kept all the master drawings in a large plan chest alongside his drawing board in the rear 'office' at 'Bardonela' and would update them as required on receiving input from builders. The Myford 254 was adjacent. The plan chest had stacked upon it large packages of his favourite packets of cigarettes.

A few steps away from the door of the rear 'office' was Don's workshop shed transported from Smithards Lane, Cowes, containing Gordon Chiverton's original Myford ML7 which Don acquired when Gordon upgraded to a new Myford Super 7.

I often drove John Edward's 5"g Black 5 which was the first to be finished to Don's design, and it was probably John's best loco, and very well it went, and pulled the punters every Summer weekend in those halcyon days in the mid 1980s. John did enter it in IMLEC but didn't do too well.

I always thought the tube layout and sizing could be improved upon as the free gas area through the tubes compared to the grate size always seemed to me to restricted, and I recall Don commenting on this to me.

Cheers,

Julian

|

|

|

|

Post by runner42 on Jun 24, 2018 8:14:56 GMT

This is a hurried reply because SWMBO is about to shout to me to come into dinner. Of perhaps general interest I am going to use 2.5mm hex drive round head stainless steel screws that I purchased from China at a very cheap price which will be ideal for fixing the brackets to the mainframes. Happenstance, if you require to tap the mainframes instead of using nuts and do not have a 2.5mm tap then 7BA is near enough to be good enough. In this application the tools required for fixing would allow access to clear the main bracket piece and the round head giving the near appearance of a rivet head.

Julian as always you provide good information but it's a bit early to have any relevance to me, but never the less thank you.

Brian

|

|

|

|

Post by doubletop on Jun 24, 2018 21:02:38 GMT

This German firm doesn't do square head nuts and bolts for fasteners in the 2 -4 mm range does it? Richard I've just had a look Richard. I'm afraid they don't. But have a look here to see their range. You'll probably need to get Mr Google to translate it for you! Mike Thanks for the heads up, it looks like a very usefull resource. The link is now doing the rounds of the Wellington guys. Although, I'm a bit of a BA luddite as all my locos were originally built using BA. Pete |

|