|

|

Post by donashton on Jan 11, 2015 21:06:06 GMT

Hi Ross,

"700 can't be wrong" is a bold but safe boast if the definition of 'wrong' is rather blurred. Stephenson's gear exhibits a reversal of the lead condition according to the use of crossed or uncrossed eccentric rods. Since the Allan gear straight link and double hanger arrangement is usually close enough to a straight line the lead should remain about the same however driven. However,the eccentrics as a pair should sit with the crank dead on centre, and be all in line and symmetrical about the inclined centreline. BUT they are not on the drawing and the only given 9/64ths measurement is ambiguous.

Problems inherent with Allan link are mostly to do with the hangers, especially one which is effectively a very short lever and the other not much better - 700 can't be wrong but I prefer a proper gear, properly designed and dimensioned (no idea from what is given about the valves and ports). AND don't tell me it is OK 'cos it is scaled from the full size - there have been far too many professional lapses.

Don.

|

|

|

|

Post by donashton on Jan 11, 2015 22:14:35 GMT

Just a little more, following my previous post: any hanger which is going to affect the valve movements ought to have the long arm connection to the link's forward end. That helps a smoother forward operation and leaves the more rarely used backgear to suffer the ducking and diving of reverse.

Don.

|

|

|

|

Post by suctionhose on Jan 11, 2015 22:16:13 GMT

Don,

You know me well enough not to suggest I would blindly follow fullsize with out question. I felt the "bold statement" was necessary to quell Julian's enthusiasm for regurgitating something he got second hand from you in the course of telling us we are all idiots.

Granted the 9/64ths erroneously references the vertical centreline instead of the inclined centreline but even that produces a small error in the context of the whole Allan approximation (provided the advance is mirrored identically either side of the crankpin)

As I believe I have said my the previous contris to this post: -

1. Eccentrics have to equally advanced either side of crank and this must be achieved first and without the gear assembled.

2. Allan is not as good as Stephenson's in any way (except possibly in terms of low head room to move link up and down)

3. Representatives of the 700 fullsize were less than perfect.

The last Allan geared engines here were retired from active duty in 1986. Of course several live on in preservation. They aren't GWR but they have nothing to be ashamed of. They were fit for purpose as history has shown.

As for Ned and his uncertainties, he has accepted the design as drawn and now needs to look for the result in simple terms. I have known EJW for over 30 years and I am quite sure the design of Allan he has adopted would be scaled from fullsize drawings rather than designed from scratch.

I have read the analysis of Allan by Simon Bowditch and yourself and to accept that it has deficiencies is only to confirm what we already know. There are not the "how to instructions" available like that which you have generated for Stephenson's and Walschaert's.

Glad you are fightin' fit for 2015!

|

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Jan 11, 2015 22:33:57 GMT

hi ross,

your above post is somewhat disingenuous towards me! i take no offence, as always value your comments, and am more than happy to be corrected when proved wrong! however i think if you read between the lines both don ashton and myself find something amiss with the E.J. Winter's layout of the Allan valve gear. whether or not it is exactly correct to prototype is quite another matter!

and for the record i didnt regurgitate something i 'got secondhand' from don re Marie E. we discussed the matter at some length at the time and both arrived at the same conclusion, and i have all my emails with don to back up same, though i dont record our regular telephone conversations however fascinating they may be when listening to all of don's astute observations! perhaps they ought to be recorded!!

cheers,

julian

|

|

|

|

Post by suctionhose on Jan 12, 2015 0:02:35 GMT

Julian,

Jousting with you is one of life's pleasures! Unfortunately, wading in with "this is all bollox" splashed across your tee shirt does not help Ned in the least. The Thread is about Ned, not you or me after all.

We aren't experts in everything by a long way but we do know something of our own engines including the fact Allan gear is not as good as GWR Stephenson's. Give us some credit!

The mission here is to help Ned make the best of what he's got. It will be satisfactory and he will drive and enjoy that engine. At this point he does not need a 7 plank wagon full of theory that makes him wish he'd never left the cricket.

|

|

|

|

Post by donashton on Jan 12, 2015 7:30:32 GMT

Hi Ross,

Perhaps I should take the can here. I certainly agree with your splendid no-nonsense aid for Ned but I notice the column of those who have read the thread - always far exceeding actual participants. By this means the forum also addresses those interested in the thread yet not specifically tied to it or wanting to comment.

And quite out of topic - thanks for your good health wishes re 2015, though currently2015 does no better than 2014!

Don.

|

|

|

|

Post by NSWGR Steambuff on Jan 12, 2015 8:04:20 GMT

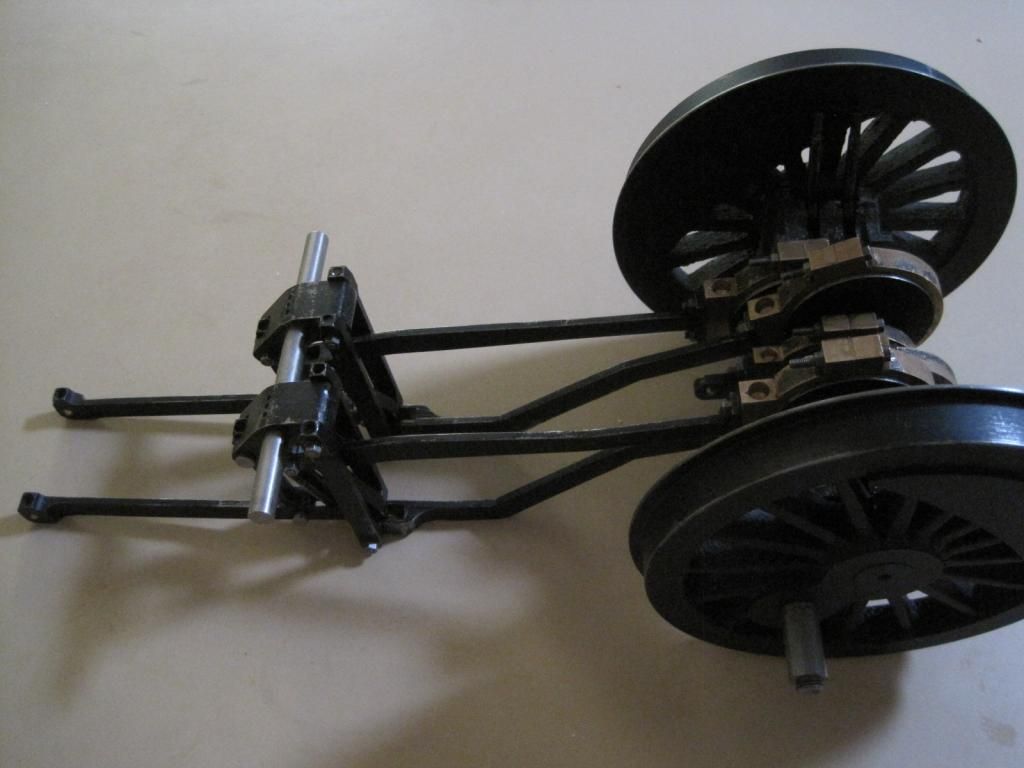

Well that discussion was interesting. I have spent all day disassembling and reassembling the valve gear to the point where I think I could do it blindfolded. I followed Shawki's advice and looked more closely at the assembly where I found the clevis ends of the eccentric rods to not have enough clearance to allow the expansion link to rotate freely at the extremity of their movement (if that makes sense). Bottom line is after much filing and refitting, the eccentrics now rotate freely without any binding. It wasn't the positioning of the eccentrics as I originally thought. As I had the assembly removed from the frames, I thought I would take a couple of photos for those interested. As the radius rod ends aren't connected to anything at the piston end, some of the angles shown won't look right. A bit of paint touching up also required after all the work. I live very close to the coast so rust prevention is high on the priority list. First one overall  Second in reverse gear  Third in forward gear.  As Shawki has built this engine to the EJW drawings and it works, seems to say the valve setup in the drawings must be correct. Correct in the sense that it works. Not so sure if it is prototypical. I am trying to get hold of a book written by Ron Preston which is specifically on the P or C32 class of engine as used in Australia. I think I will attack the brakes next, followed by the linkages for the drain cocks, plumbing for the axle pump, then probably the cylinders. Thanks to all who replied, especially Ross who gave me some confidence that I hadn't stuffed it up by blindly following a set of drawings. Ned |

|

|

|

Post by donashton on Jan 12, 2015 9:51:48 GMT

Hello Ned,

Glad that you now feel more sanguine of success, and thanks for posting the photos.

Don.

|

|

|

|

Post by suctionhose on Jan 12, 2015 11:11:05 GMT

|

|

|

|

Post by Jim on Jan 12, 2015 21:05:10 GMT

Here's 3265 heading a transfer train through very familiar country between Goulburn and Junee, NSW . www.youtube.com/watch?v=ax6dilbzpWUSorry Ned, have lots of happy memories of going on holidays behind a C32. Jim |

|

|

|

Post by suctionhose on Jan 13, 2015 0:32:27 GMT

For the benefit of discussion, here is a scan from the "drawing under the bed". It shows the layout of Allan gear used by Mr Thow on the 50 class in 1896, just 4 years after the 32's were introduced. Notice the link is now a "centrally suspended Launch type" . Perhaps Don A would care to comment on the virtues of this change.  |

|

|

|

Post by suctionhose on Jan 13, 2015 1:05:08 GMT

|

|

|

|

Post by Jim on Jan 13, 2015 5:36:40 GMT

Yes indeed Ross, lovely to see 3265 working on it's own free of diesel fumes. The Governor General's carriage would look just great behind your C32 Ned, the next project after this one's completed?  Jim. |

|

|

|

Post by NSWGR Steambuff on Jan 13, 2015 9:24:30 GMT

Here's 3265 heading a transfer train through very familiar country between Goulburn and Junee, NSW . www.youtube.com/watch?v=ax6dilbzpWUSorry Ned, have lots of happy memories of going on holidays behind a C32. Jim Jim, Absolutely no need to apologize. I welcome all input, especially if it is in regard to the C32. I enjoyed the videos you and Ross posted. It all adds to my learning more and therefore hopefully help me with my build. I know there are good reasons for it, but it is a shame to see those dirty polluting diesels hooked up to a fine steam locomotive. Thanks for the kind comments on the rods. Cheers, Ned |

|

|

|

Post by NSWGR Steambuff on Jan 13, 2015 9:30:36 GMT

Jim, A good thought, but I have a looong way to go on the engine. Ross, Now that you have bought it to my attention, I see what you mean by the irregular beat of the C32. Does that mean I have an excuse if the timing isn't exactly the same for each stroke on mine when it is done??  Cheers, Ned |

|

|

|

Post by ejparrott on Jan 13, 2015 9:58:36 GMT

My meagre understanding of valve gear says the centrally hung link will be much better, but underneath it is still the straight link!

|

|

|

|

Post by donashton on Jan 13, 2015 17:22:55 GMT

Quite right Ed, but it has necessitated a large offset, and now it is not necessary why do we still have those awkward crossed rods?

Ross, I wish I could conjure up such fascinating stuff from under my bed!

The five years between C32 and C50 show a bit of juggling and a hybrid link partway between loco and launch. One wonders why.

My guess is that the answers are based in history. Once we have the Howe link those with the least inkling of geometry, and in an age rife with patent, Gooch and Allan were inevitable but much inferior. Even Stephenson's gear probably had more bad designs than good.

How bad is bad? If the GWR could easily achieve event equality of 1 or 2% then that should be the aim. What you hear on the videos is at a guess at least 10% discrepancy.

Thanks Ross,

Don.

|

|

|

|

Post by suctionhose on Jan 13, 2015 21:29:16 GMT

The rods have to be crossed because the link is up for forwards - opposite of Stephenson's.

For those unfamiliar, pay close attention to the weighshaft and see the the act of tilting the reachrod forward - from the reverser in the cab - both raises the link and lowers the valve rod.

The dual movement allows the die block travel to approximate a straight vertical line. This might have been the 'Eureka!' moment Allan had that lead us into this mess!

Actually, the link raises and lowers only slightly, perhaps 30% of the slot. The rest is up to the valve rod.

I suspect Thow's first version of the gear - for the 32 - suffered for having a loco link and end suspension. The former exacerbating the angular errors by requiring larger eccentric throws and the latter - well as Ed said, central is best.

|

|

|

|

Post by ejparrott on Jan 13, 2015 22:11:11 GMT

Don and I...well Don really!...have tweaked my Manning Wardle valve gear by converting to center hung so it runs better...its being built for hard work, not a 100% accurate museum piece

|

|

jma1009

Elder Statesman

Posts: 5,922

|

Post by jma1009 on Jan 13, 2015 22:58:12 GMT

i do like very much the C32 loco that Ned is making a fantastic job of restoring. i am very fond of some of the older 'down under' locos, some of which are very alike to much missed and long scrapped UK locos.

i have always been very interested in the Allan valve gear because many of my favourite locos have this gear fitted.

i fully appreciate that the simple weighshaft, reach rod, and lever reverse arrangement on the C32s lends itself to an 'upside down' arrangement of the valve gear. however valve events in Allan valve gear create a number of compromises between equal leads and equal cut offs. to reduce these compromises or deficiencies the valve gear needs to be very well laid out. i am far from convinced that the C32 (or class 50) arrangement is the optimum layout for good valve events with Allan valve gear.

i am however very pleased that Ned has found a cause and solution to the original problem with the valve gear binding, though his description of the eccentrics being at the wrong settings sparked off my criticism of the valve gear layout.

Ned,

please dont be in any way put off by some of us discussing the finer points of Allan valve gear on your thread! you are doing a superb job!

cheers,

julian

|

|