|

|

Post by Jim on Jan 14, 2015 3:23:02 GMT

i do like very much the C32 loco that Ned is making a fantastic job of restoring. i am very fond of some of the older 'down under' locos, some of which are very alike to much missed and long scrapped UK locos. Snipped..... Ned, please dont be in any way put off by some of us discussing the finer points of Allan valve gear on your thread! you are doing a superb job! cheers, julian I couldn't agree more , your C32 will look stunning when completed.  Jim |

|

|

|

Post by donashton on Jan 14, 2015 7:11:35 GMT

Nothing to do with Ned's thread - thanks lads for the good wishes, but 'fighting fit for 2015' is a bit of a dream just yet. I think I'm on crossed rods at present!

The close colonial links of the late 19th century are somewhat responsible for the tendency for British makers to dominate. There were numerous antipodean locomotive engineers of excellence whose work ought to be better recorded.

Don.

|

|

|

|

Post by suctionhose on Jan 14, 2015 10:58:51 GMT

The close colonial links of the late 19th century are somewhat responsible for the tendency for British makers to dominate. Don. Then spare a thought for Thow's predecessor, Mr E E Lucy, who bravely stood up in Parliament and said, "Lets buy engines from America". Talk about upset the apple cart...! |

|

|

|

Post by Rob on Jan 14, 2015 12:45:26 GMT

The close colonial links of the late 19th century are somewhat responsible for the tendency for British makers to dominate. Don. Then spare a thought for Thow's predecessor, Mr E E Lucy, who bravely stood up in Parliament and said, "Lets buy engines from America". Talk about upset the apple cart...! Got his wish in the end, didn't he! |

|

|

|

Post by NSWGR Steambuff on Jan 15, 2015 11:26:28 GMT

Good stuff guys,

I welcome all the input, and have learned a lot more about the Allan valve gear.

I also enjoy the historical data coming out of this discussion.

It reinforces my admiration for what these engineers were able to do at the time with the resources available to them.

It may be a while before I post again due to family commitments, but feel free to keep the info flowing.

Cheers,

Ned

|

|

|

|

Post by suctionhose on Jan 16, 2015 7:52:06 GMT

The close colonial links of the late 19th century are somewhat responsible for the tendency for British makers to dominate. Don. Then spare a thought for Thow's predecessor, Mr E E Lucy, who bravely stood up in Parliament and said, "Lets buy engines from America". Talk about upset the apple cart...! sorry. Memory lapse. Lucy followed Thow. I meant Whitton, Midleton, Eddy et al. Purchased consolidations from Baldwin (J's). Historical accounts site volatile politics and blood ties with England and Scotland that were not happy! |

|

|

|

Post by NSWGR Steambuff on May 15, 2015 11:50:58 GMT

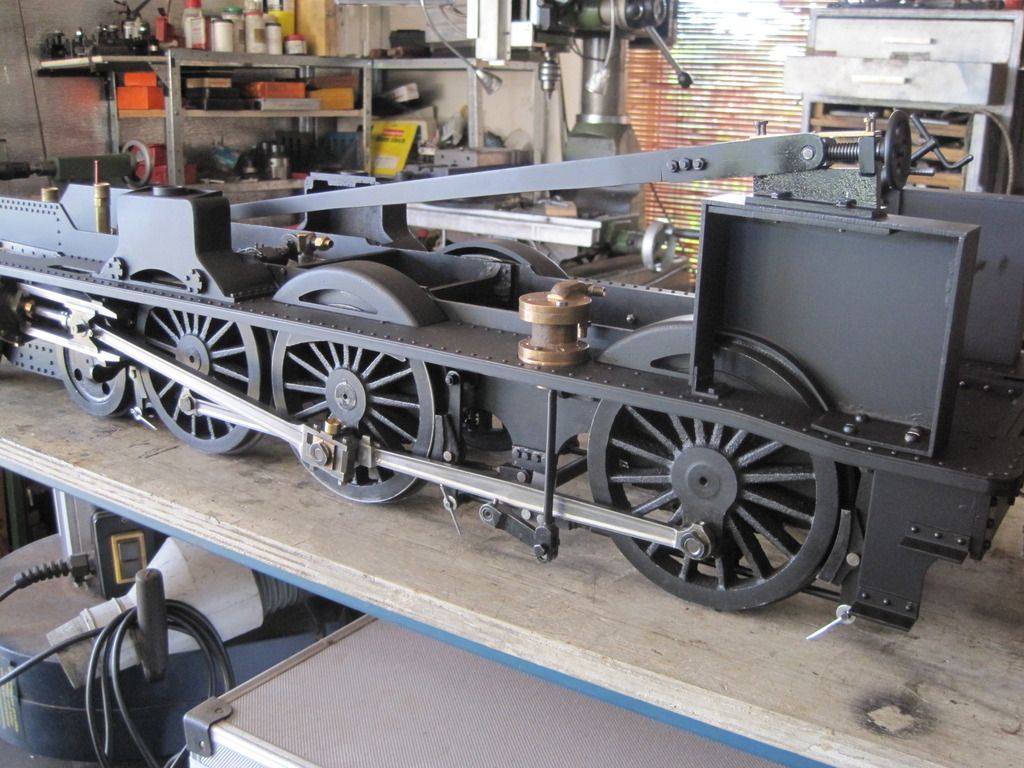

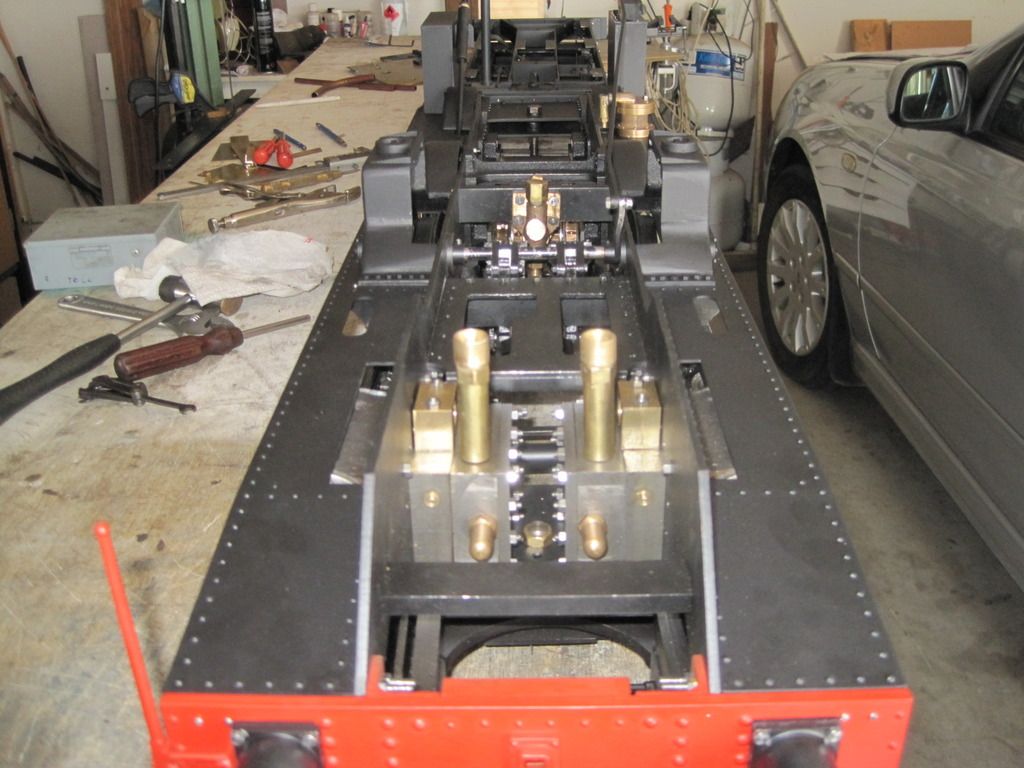

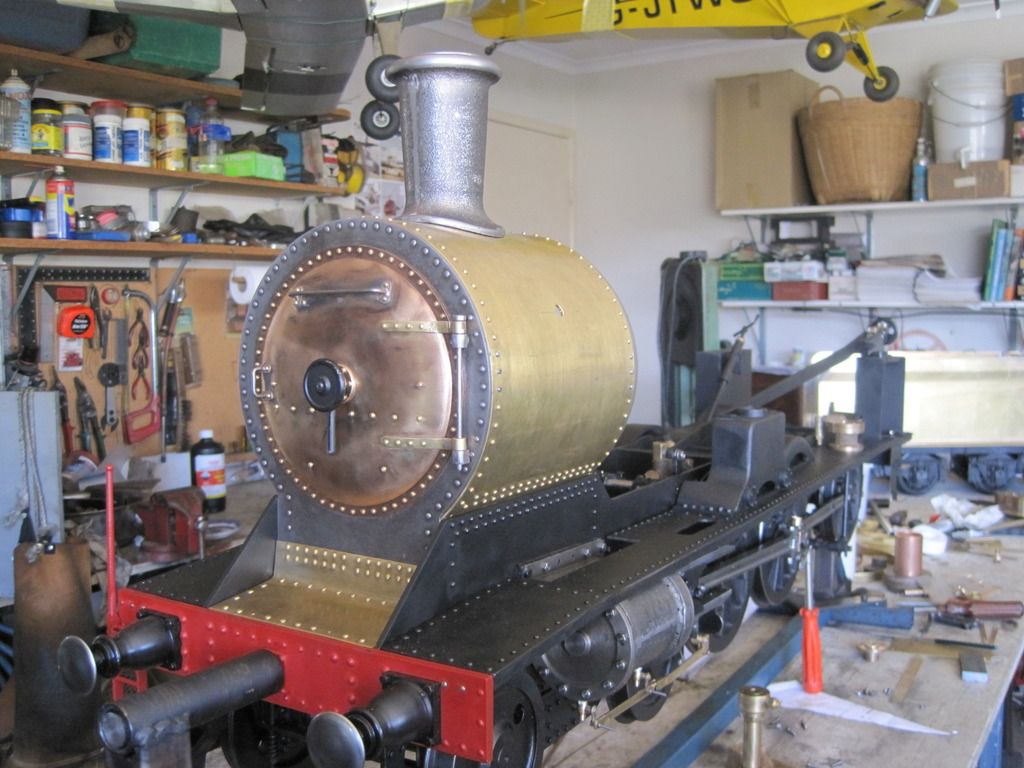

Hello to all, I have been beavering away on my C32 build now for almost a year now, and thought it might be time to provide a little update. The build is now at the stage where I can say that that most of the chassis/running gear on both the tender and engine is complete, but minus a few details like cladding of the cylinders and the like. The next step I see will be making the smoke box followed by the boiler, and I must admit I approach both with trepidation, as sheet metal work and boiler construction are both very foreign to me. The sheet metal lack of know-how is the reason I haven't attempted the superstructure on the tender yet. The boiler will be built to the Australian code and inspected/tested accordingly, so to achieve that, I will be asking many questions. I got the engine to run an air about a week ago after much frustration with the timing, such that it now runs quite well on around 10 PSI air pressure. I must thank Ross (AKA Suctionhose) for his time and patience via PM's in helping me understand the basics of getting the timing right. A few photographs of the progress so far: First mating of engine to tender to get an idea of the size       I have one question for those in the U.K. Is there a commercial source in the UK for 5" scale Beyer Peacock builders plates? I understand some of these engines had a builders plate mounted on the side of the sand boxes. I saw them on Shawki's thread and he told me he had his made quite a few years ago, so thought I would ask before trying to get some made. Cheers, Ned |

|

|

|

Post by Jim on May 15, 2015 13:30:42 GMT

Your 32 class is looking superb Ned, you're doing a great job. I have many memories of seeing them working through Katoomba in the Blue Mountains in the midst of winter with the canvas curtains pulled across the cab 'port hole' windows and the storm sheets rigged to try and keep out the icy winds and driving rain.

Jim

|

|

|

|

Post by ejparrott on May 15, 2015 14:09:52 GMT

There are a couple of people who can produce plates, I've used Peters Plates for a builders plate for mine, plus a headboard...I'm trying to get in touch with him to make me some more but I'm struggling to get in touch with. There are others, Diane Carney used to do them but I think she's quit now, Steam plates I think is another. Loving the progress  |

|

|

|

Post by fostergp6nhp on May 15, 2015 16:26:11 GMT

That's looking rather good.

|

|

|

|

Post by Jim on May 15, 2015 22:34:13 GMT

Just a thought Ned, it could be worth having a chat with Barry Potter of the Orange Society of Model Engineers regarding builder's plates. Barry's models are the gold standard for NSWGR locomotives, I believe one of his models of a 59 class is in the Power House Museum.

Jim

|

|

|

|

Post by Shawki Shlemon on May 17, 2015 10:03:55 GMT

Well done Ned , very nice work , this will be a lovely engine .

|

|

|

|

Post by NSWGR Steambuff on Jul 31, 2015 10:40:16 GMT

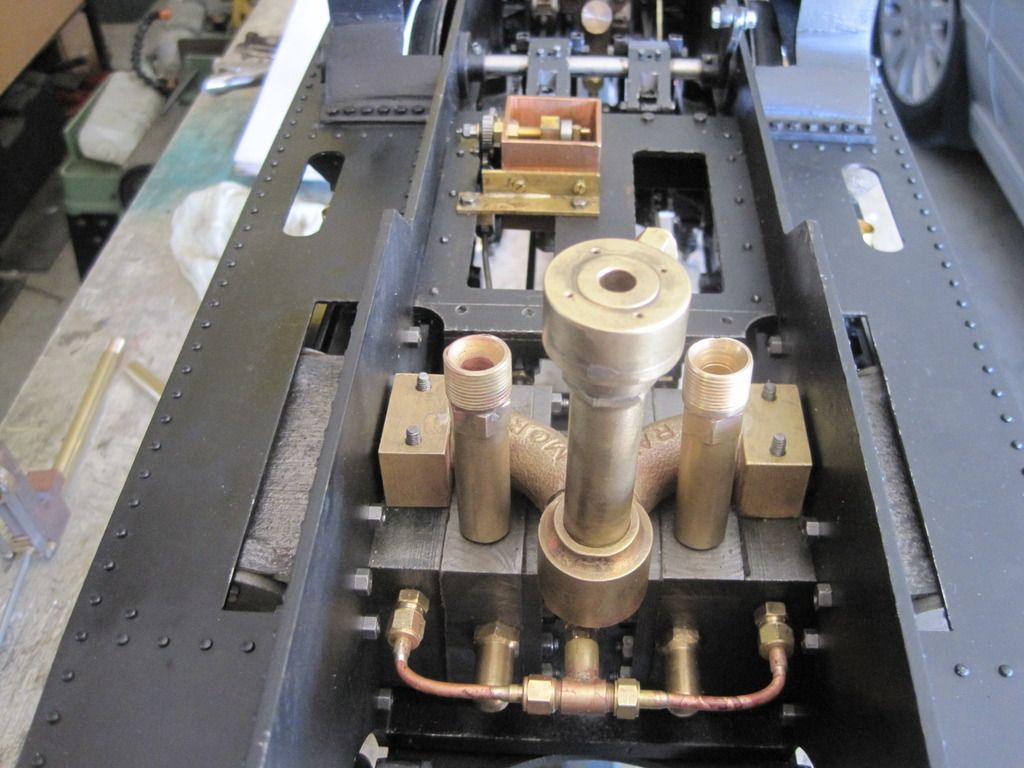

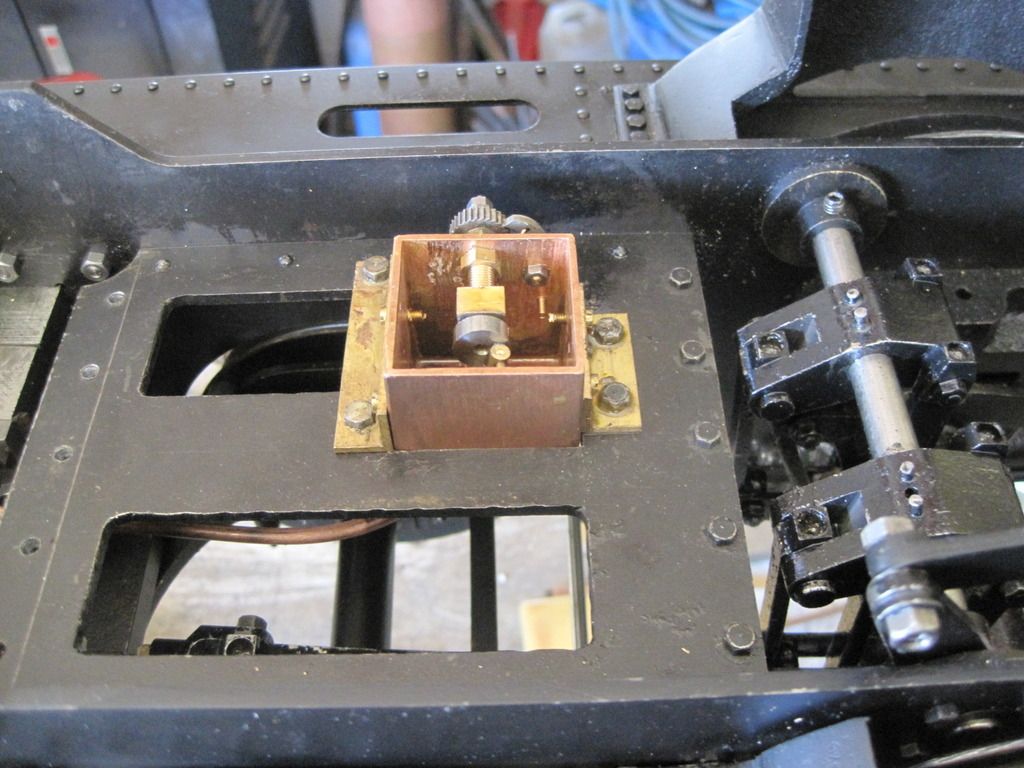

An update on progress so far. Getting close to having to have a go at building the boiler, which is something I am not looking forward to. I say that because it is something I have never done before. I have a copy of the Farmer book which I have been looking at closely, but once again the unknown is rather daunting, to me at least. The tender is coming along - sheet metal work is not my favourite activity.  Tender hand pump made and installed  Smoke box almost complete  Blast pipe, steam inlets, and lubricator lines installed  Lubricator installed and connected  I am waiting on a couple of fittings to finish off the smoke box. I have to say (once again), the new owner of Ernie Winter's business has been less than helpful when it comes to supplying parts. I could say a lot more, but don't need a libel suit at this stage of my life. I have been getting some parts from the UK which takes a little longer, but at least is reliable. Enough said on that front. Now for some more pondering over the boiler build. Cheers, Ned |

|

|

|

Post by alanstepney on Jul 31, 2015 11:43:10 GMT

Given the workmanship so far, you wont have any trouble with the boiler.

Jast take it steadily, one section at a time, and perhaps some practice joining some odd pieces together first, and all will be well.

Of course, you could always send me a plane ticket so that I could help!

|

|

|

|

Post by Jim on Aug 1, 2015 1:29:17 GMT

That's a lovely job you're doing Ned. I must say that is a neat space saving solution you've hit on to fitting the swept branch for the exhaust. Must keep that in mind if I ever start a second loco.  Jim |

|

|

|

Post by NSWGR Steambuff on Aug 1, 2015 2:35:43 GMT

Thanks Alan - when can you leave?? :-)

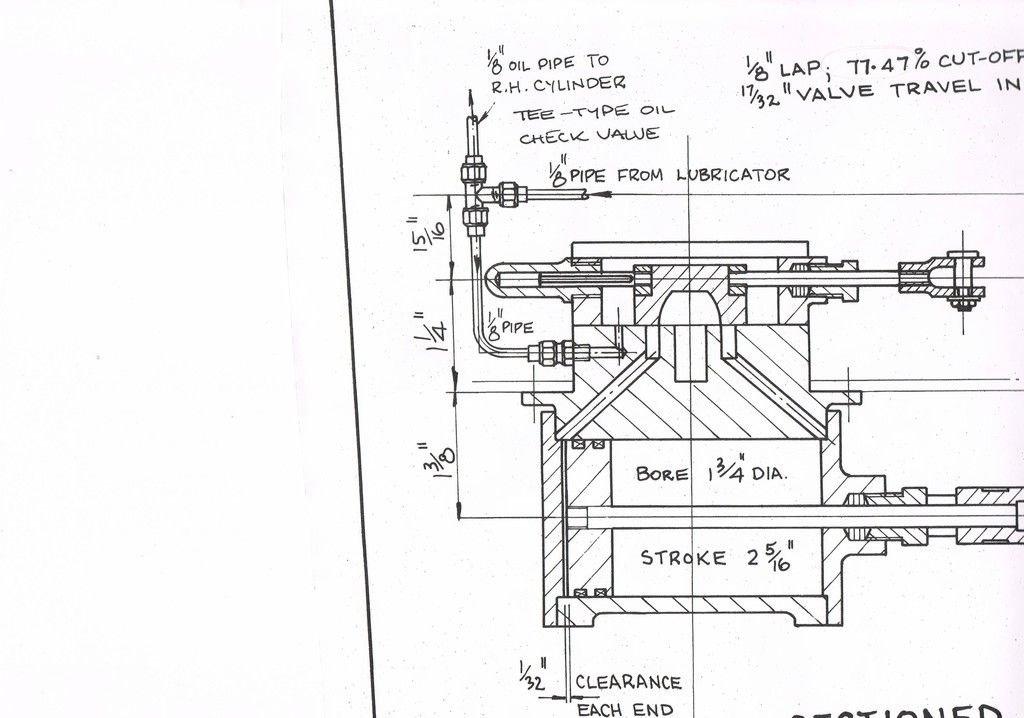

Jim, I can't take any credit for the exhaust design. It is as per the plans with the exception that I happened to find the brass fitting in my collection of old plumbing accessories which fitted the bill. It was an old 'T' piece where the junction is more like a 'Y', so I just cut off all the socket ends and silver solder some copper pipe in to take the fittings you see. The plans actually called for bent copper tube between the brass blocks on the steam chests and the base of the blast pipe.

Thank you both for your words of encouragement.

|

|

|

|

Post by Shawki Shlemon on Aug 2, 2015 8:05:56 GMT

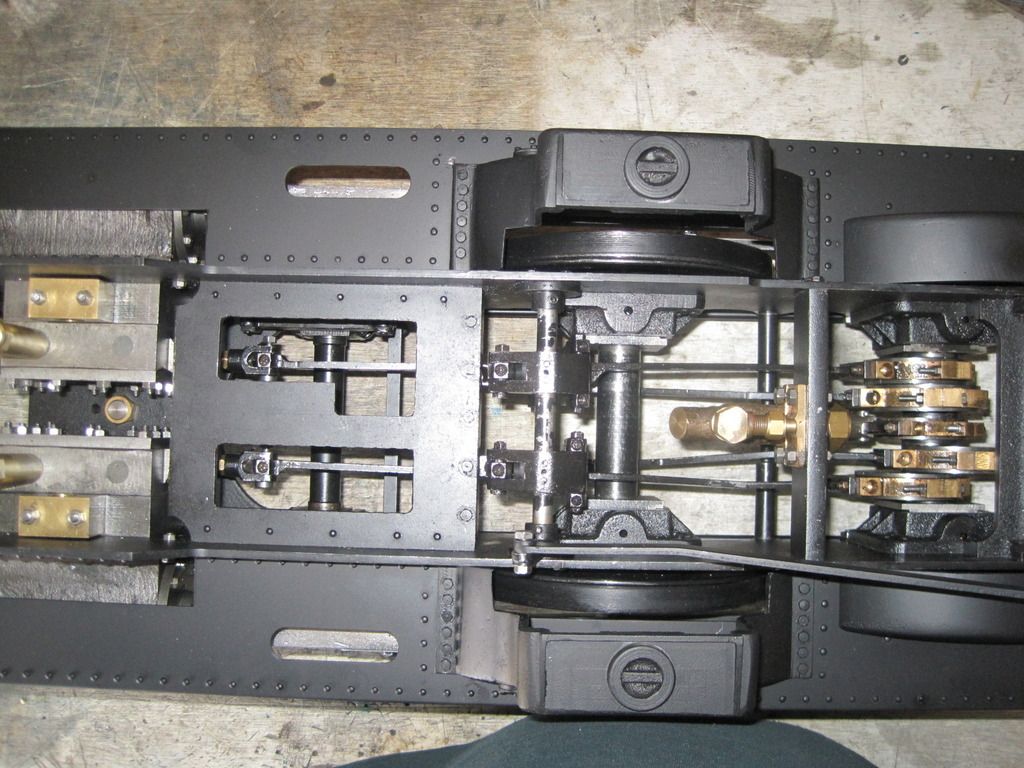

Hi Ned , The work is excellent , this is going to be a lovely model . I have one query , the oil pipes seems connected to the cylinder block and not to steam chest , am I missing something ? may be I don't remember the details .

|

|

|

|

Post by NSWGR Steambuff on Aug 2, 2015 11:54:07 GMT

Hi Ned , The work is excellent , this is going to be a lovely model . I have one query , the oil pipes seems connected to the cylinder block and not to steam chest , am I missing something ? may be I don't remember the details . Cripes Shawki, you scared the living crap out of me when you asked that question and I went back and looked at the photograph. Initial thoughts were Oh no!, how does the oil get to the slide valve. How could I be so stupid??? I rushed out and dug up the cylinder plans (10 PM) and to my relief realized what was going on. It had been quite some time since I had worked on the cylinders and steam chests, hence the scare. Just goes to show how an experienced set of eyes can spot the obvious. Thanks Shawki for pointing it out though. This photograph will explain  |

|

|

|

Post by Shawki Shlemon on Aug 3, 2015 9:00:43 GMT

|

|

|

|

Post by NSWGR Steambuff on Nov 12, 2015 1:26:14 GMT

Things have slowed down a bit since my last post thanks to a compressed fracture of a vertebra. I have been working slowly at the boiler components and am almost at the stage of beginning to start silver soldering. That should be interesting since I have never built a boiler before. It was interesting working with 3 mm copper sheet, and not quite as difficult as I had imagined, although I learned very quickly to stop and reheat as soon as it work hardened. My club boiler inspector has been very helpful with advice and some very helpful tips on buying silver solder for a reasonable price and other building advice. Not much to show other than the components completed so far.  |

|